In the wave of modern manufacturing transformation towards "functional integration, experience upgrading, and efficiency improvement", Overmolding, as an advanced multi-material injection molding process, is breaking the performance limitations of single materials. It perfectly integrates rigidity and flexibility, strength and texture, functionality and aesthetics, becoming a core technical support for product innovation in many fields such as consumer electronics, automotive, and medical devices. It not only reshapes the design logic of products but also promotes the development of manufacturing towards refinement, high efficiency, and high added value, serving as a key bridge connecting material properties and product needs.

I. What is Overmolding?

Overmolding, literally translated as cladding molding (also known as overmold molding or two-shot molding), is essentially a special injection molding technology. Its core is to realize continuous molding of two or more materials with different properties (usually rigid substrates and flexible cladding materials) through one or more injection molding processes in the same set of molds (or multiple matching molds), and finally form an integrated component with a complete structure and firm interface bonding.

Different from the traditional multi-component assembly process, Overmolding does not require auxiliary materials such as adhesives and fasteners. Instead, it achieves permanent fusion of different materials through mechanical interlocking, interface roughening, or chemical bonding, which not only avoids errors and looseness during the assembly process but also greatly simplifies the production process. Its core logic is "layered but not distracted" — different materials perform their respective functions: the rigid substrate provides structural support and strength, while the flexible cladding material optimizes functions such as touch, sealing, and anti-slip, ultimately achieving a "1+1>2" product performance upgrade.

Simply put, most of the tools with soft rubber grips, two-color mobile phone cases, automotive steering wheels, and medical surgical handles we use daily are manufactured through the Overmolding process, which has long penetrated all aspects of life and industrial production.

II. Core Process Types and Flows of Overmolding

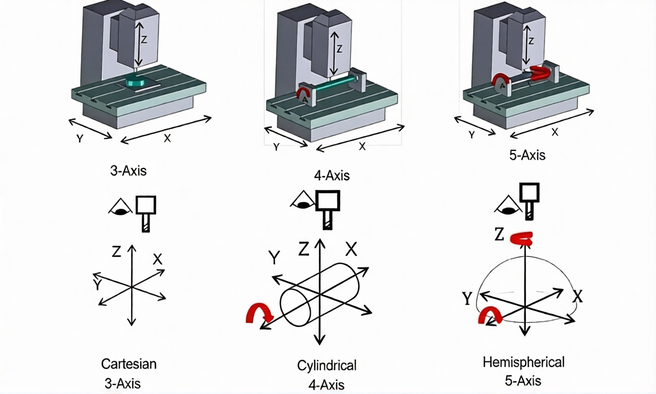

According to the differences in production equipment, mold structure, and molding times, Overmolding is mainly divided into three core types. Different types adapt to different production needs and product scenarios, each with its unique advantages and application boundaries:

(I) Core Process Types

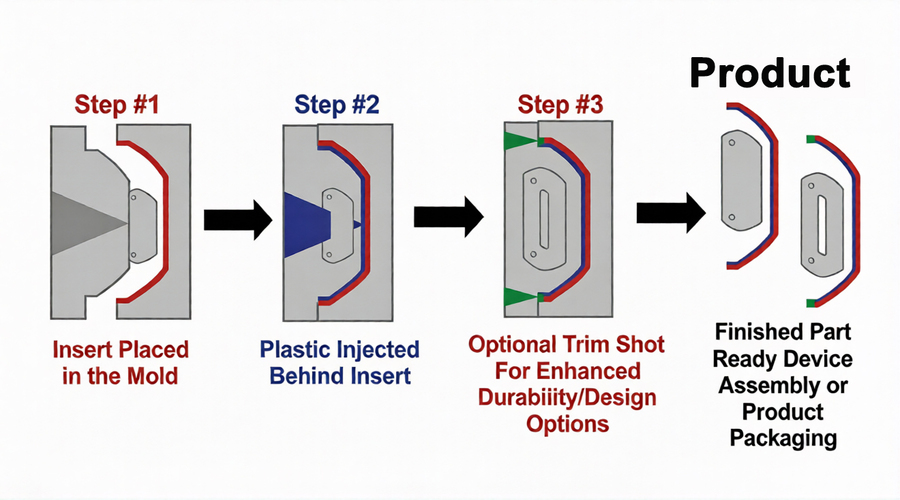

1. Insert Overmolding: This is the most basic and widely used type, belonging to a low-cost solution. The core of the process is to first insert a prefabricated substrate (which can be plastic, metal, glass, etc., usually metal inserts or rigid plastic parts) into the second set of injection molds manually or through automated equipment, then inject the cladding material (usually flexible materials such as TPE, TPU, and silicone) into the mold to coat the surface of the substrate, and form an integrated product after cooling and solidification. This type can be completed using ordinary single-shot injection molding machines with low mold costs, suitable for small and medium batch production. However, manual insertion may affect production efficiency, and positioning accuracy needs to be optimized through automated jigs.

2. Two-Shot/Multi-Shot Overmolding: Also known as 2K molding, it is a high-end precision process. It requires a special injection molding machine equipped with two or more barrels and a rotatable mold. Without taking out the substrate, the mold can automatically rotate the station, inject the substrate material and cladding material in turn, and complete multi-material cladding in one production cycle. This type has high production efficiency, high product precision, and firmer interface bonding, which can realize complex structures and multi-color fusion, suitable for mass production of high-precision products. However, the initial investment cost of equipment and molds is high, and the technical threshold is also higher.

3. Co-Injection Overmolding: Two materials are in a molten state at the same time and injected into the mold through the same gate to realize synchronous molding and fusion of the substrate and the cladding material. This process can achieve seamless connection of materials with extremely high bonding strength, but it is difficult to control and has high equipment costs. It is mainly used for high-end products with extremely high requirements on interface bonding strength, such as precision medical devices and aerospace components.

(II) General Process Flow (Taking Insert Type as an Example)

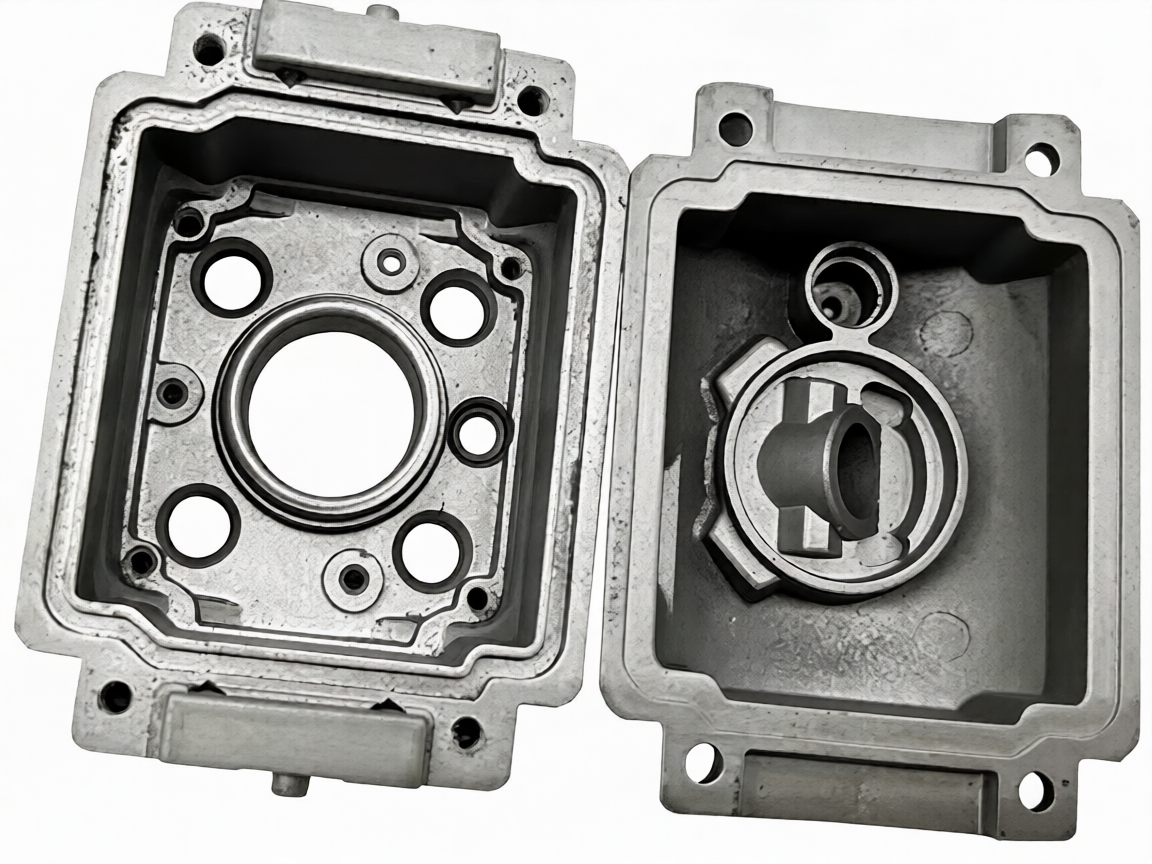

1. Substrate Preparation: Manufacture rigid substrates through injection molding, machining, and other processes. Ensure that the surface of the substrate is clean, free of oil and oxide layers. If necessary, perform surface roughening, plasma cleaning, and other pre-treatments to improve the bonding force with the cladding material;

2. Mold Preparation: Install and debug the overmolding mold. Adjust the mold gap and temperature zoning according to the difference in thermal expansion coefficients of materials to ensure accurate positioning of the substrate;

3. Substrate Positioning: Insert the pre-treated substrate into the positioning mechanism of the mold and fix it through auxiliary equipment such as vacuum jigs to prevent displacement during injection molding;

4. Injection Cladding: Heat and melt the cladding material, inject it into the mold cavity to coat the designated area of the substrate. Strictly control the injection temperature, pressure, and speed to avoid defects such as bubbles and material shortage;

5. Cooling and Solidification: Control the cooling time and temperature according to the material properties to ensure full fusion and shaping of the two materials, and avoid warping and delamination caused by uneven cooling;

6. Demolding and Post-Treatment: Open the mold to take out the finished product, remove excess parts such as gates and burrs, and perform post-treatments such as polishing and testing if necessary to ensure that the product meets quality standards.

III. Key Technical Points of Overmolding

The core difficulty of Overmolding is to achieve firm bonding of different materials and product precision control. Its quality mainly depends on three key factors, which are also the key technical points focused on in the industry:

(I) Material Compatibility: The Core Premise of Firm Bonding

Material selection directly determines the bonding strength, durability, and service life of the product. The core principle is that "the substrate and the cladding material must have good compatibility". Common material matching follows the "polarity matching" principle, and priority is given to material combinations that can form chemical bonding or mechanical interlocking:

• Rigid Substrates: Commonly used are ABS, PC, PA (nylon), PBT, liquid metal, etc. Among them, liquid metal has become the preferred substrate for high-end products due to its high surface flatness and no oxide film, which can achieve high-strength bonding with various engineering plastics;

• Flexible Cladding Materials: Commonly used are TPE (thermoplastic elastomer), TPU (thermoplastic polyurethane), silicone, etc. Among them, silicone has excellent high-temperature resistance and biocompatibility, suitable for medical devices and high-end consumer electronics; TPE is easy to mold and has a soft touch, widely used in daily consumer goods;

• Compatibility Tips: Prioritize materials with similar polarity (such as PC and TPE, PBT and TPU), and coupling agents can be added to enhance chemical bonding; avoid using materials with excessive differences in melting points to prevent the substrate from melting or the cladding material from being unable to fully mold during injection molding; the moisture content of the cladding material should be controlled below 0.02% to ensure injection molding quality.

(II) Mold Design: Guarantee of Precision and Stability

The mold is the core carrier of the Overmolding process. Its design level directly affects product precision, bonding quality, and production efficiency. The key design points include:

• Gap Control: According to the difference in thermal expansion coefficients of the substrate and the cladding material, reasonably design the mold gap — the bonding interface gap is controlled at 0.03–0.05mm, the lock area gap is controlled at 0–0.02mm (to ensure mechanical bonding strength), and the free boundary gap is ≥0.1mm (to prevent plastic stress concentration);

• Temperature Zoning: Due to the large difference in molding temperatures of different materials (for example, the mold temperature of the liquid metal section is about 280°C, and the mold temperature of the plastic section needs to be controlled at 70–120°C), heat insulation inserts or cooling channels need to be set in the mold to achieve temperature zoning control, avoiding local carbonization of plastic or deformation of the substrate;

• Positioning Structure: Adopt the method of pre-installed jigs + vacuum positioning to ensure that the substrate does not displace during injection molding. Especially for small and precision parts, the positioning accuracy needs to be controlled within 0.01mm;

• Runner Design: The runner should be smooth and free of dead corners to ensure that the molten cladding material flows evenly and covers the surface of the substrate, avoiding defects such as material shortage, bubbles, and weld lines.

(III) Process Parameters: Details Determine Product Quality

The parameter control during the injection molding process directly affects the material fusion effect and product appearance. The core parameters include:

• Temperature Control: The substrate temperature needs to be adjusted according to the material properties. Maintaining an appropriate temperature can improve the bonding force with the cladding material; the melting temperature of the cladding material needs to be strictly controlled (such as 180–220°C for TPE and 160–180°C for silicone) to avoid material degradation and discoloration caused by excessive temperature;

• Injection Pressure and Speed: The pressure should be uniform and stable to avoid substrate deformation caused by excessive pressure or loose cladding caused by insufficient pressure; the injection speed should be moderate — too fast is likely to produce bubbles, and too slow is likely to cause material shortage and weld lines;

• Cooling Time: The cooling time needs to be adjusted according to the product thickness and material properties to ensure full solidification and fusion of the two materials, and avoid affecting production efficiency due to excessively long cooling time or warping and delamination of the product due to excessively short cooling time;

• Time Interval: For insert overmolding, the time interval between substrate preparation and cladding injection should be shortened as much as possible to maintain the surface temperature of the substrate and improve the bonding strength.

IV. Industrial Application Scenarios of Overmolding

With the core advantages of "integrated molding, functional integration, and aesthetic upgrading", Overmolding has been widely applied in many fields such as consumer electronics, automotive, medical devices, and daily consumer goods, becoming a key process for promoting product innovation. The following are analyses of typical application scenarios:

(I) Consumer Electronics Field: Dual Upgrade of Appearance and Experience

Consumer electronics is the most widely used field of Overmolding. The core demand is to improve product touch, anti-slip performance, and appearance texture, while achieving lightweight and precision:

• Mobile Phones and Smart Wearables: Mobile phone cases (rigid PC substrate + flexible TPE cladding, anti-drop and anti-slip), smart watch straps (rigid plastic substrate + silicone cladding, skin-friendly and comfortable to wear), earphone casings (two-color cladding, achieving dual improvement of appearance and touch);

• Peripheral Accessories: Charger casings, data cable interfaces, game controller grips, etc. Flexible cladding improves grip comfort and enhances wear resistance and anti-drop performance;

• High-End Products: Laptop casings clad with liquid metal and PC, which have both high strength and lightweight, improving the high-end texture of the product.

(II) Automotive Industry: Equal Importance of Texture and Safety

The automotive industry has extremely high requirements on product durability, safety, and texture. Overmolding is mainly used for automotive interior and functional components to improve the overall vehicle value:

• Interior Components: Steering wheels (rigid plastic/metal substrate + PU/TPE cladding, improving grip comfort and anti-slip), interior panels, door armrests, control knobs, etc. Overmolding creates a high-grade texture and optimizes the ergonomic experience;

• Functional Components: Automotive door handles, rearview mirror casings, seals, etc. Cladding materials achieve anti-slip, sealing, and anti-scratch functions, improving component durability;

• Safety Components: Seat belt buckles, child safety seat components, etc. Flexible cladding improves use safety and avoids collision injuries to the human body caused by hard materials.

(III) Medical Device Industry: Priority to Safety and Practicality

Medical devices have strict requirements on material biocompatibility, safety, and precision. Overmolding achieves dual guarantee of product function and safety through the fusion of medical-grade materials:

• Surgical Instruments: Surgical handles (rigid plastic substrate + medical silicone cladding, improving grip stability and anti-slip, and meeting biocompatibility standards), tweezers, scissors, etc., optimizing the operation experience of medical staff;

• Diagnostic Equipment: Handheld diagnostic instrument casings, detection probes, etc. Overmolding achieves sealing, anti-slip, and insulation functions, protecting internal precision components and improving operation comfort;

• Other Components: Syringe grips, infusion tube connectors, medical catheters, etc. Medical-grade silicone cladding ensures chemical stability, avoids adverse reactions when in contact with the human body, and achieves sealing and leak-proof functions.

(IV) Other Fields: Diversified Expansion

In addition to the above three fields, Overmolding is also widely used in industrial tools (electric tool grips), daily consumer goods (toothbrush grips, kitchen utensil handles), aerospace (precision component cladding) and other fields. With its flexibility and practicality, it continues to expand the application boundaries.

V. Advantages, Challenges and Development Trends of Overmolding

As an advanced manufacturing process, Overmolding promotes product innovation while facing technical and cost challenges. In the future, it will develop towards more precision, higher efficiency, and more environmental protection.

(I) Core Advantages

1. Functional Integration to Improve Product Competitiveness: It integrates rigidity and flexibility, strength and texture, eliminates the need for assembly, reduces the number of parts, and endows products with various functions such as anti-slip, sealing, insulation, and anti-drop, improving product added value;

2. Simplify Processes and Reduce Production Costs: Integrated molding replaces the traditional assembly process, reducing the use of adhesives and fasteners, lowering labor and material costs, and reducing assembly errors to improve product qualification rate;

3. Optimize Appearance and Experience: It can realize multi-color and multi-texture integrated molding, making the product appearance richer and the texture higher-end; flexible cladding improves grip comfort and ergonomic experience, enhancing user stickiness;

4. Improve Durability and Reliability: Materials achieve permanent fusion through mechanical or chemical bonding, with firm bonding, avoiding loosening and falling off of traditional assembly parts, and improving product wear resistance, corrosion resistance, and service life.

(II) Existing Challenges

1. High Technical Threshold: Links such as material compatibility matching, mold design, and process parameter control all require professional technical support, which has high requirements on the R&D capability and production experience of enterprises;

2. Large Initial Investment: Especially for two-shot/multi-shot overmolding, the initial investment cost of special equipment and precision molds is high, increasing the access difficulty for small and medium-sized enterprises;

3. Difficult Quality Control: Defects such as interface delamination, bubbles, material shortage, and warping are likely to occur. It is necessary to strictly control every production link, which has high requirements on the quality inspection system;

4. Limited Material Selection: Not all materials can achieve effective cladding. The compatibility of some special materials is poor, which limits the flexibility of product design.

(III) Development Trends

1. Precision and High-End: With the improvement of product precision requirements in fields such as consumer electronics and medical devices, Overmolding will develop towards more precision, promoting the molding of miniaturized and complex-structured products, and expanding the application of high-end materials (such as liquid metal and special engineering plastics);

2. Automation and Intelligence: Introduce robots, intelligent monitoring systems, and AI algorithms to realize full-process automation of substrate positioning, injection molding, demolding, and testing, improve production efficiency and product consistency, and real-time adjust process parameters through intelligent monitoring to reduce defects;

3. Environmental Protection and Sustainability: Adopt degradable and renewable environmental protection materials, optimize the production process, reduce energy consumption and waste emissions, and conform to the global development trend of green manufacturing;

4. Multi-Material Fusion Upgrade: Break through the existing limitations of material compatibility, realize integrated cladding of three or more materials, and expand the integrated application of multiple materials such as metals, ceramics, and composite materials to unlock more product innovation possibilities;

5. Diversification of Application Scenarios: Continue to expand into fields such as aerospace, new energy, and high-end equipment, and develop customized overmolding solutions for the special needs of different industries.

VI. Conclusion

As the core technology of multi-material fusion manufacturing, Overmolding has not only changed the production mode of traditional manufacturing but also redefined the design logic and functional boundaries of products. With "integrated molding" as the core, it has achieved a perfect balance of functionality, aesthetics, and efficiency, becoming an important driving force for the innovation and upgrading of industries such as consumer electronics, automotive, and medical devices.

With the continuous progress of material technology, mold technology, and automation technology, the technical threshold of Overmolding will be gradually reduced, and the application scenarios will be continuously expanded. In the future, it will achieve breakthroughs in more high-end fields, helping the manufacturing industry develop towards refinement, high added value, and greenization. For enterprises, mastering the core technology of Overmolding will become the key to improving product competitiveness and seizing market opportunities; for the entire manufacturing industry, Overmolding is leading a manufacturing revolution of multi-material fusion, unlocking a broader space for industrial development.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.