Automation Industry Prototyping and Manufacturing Services

With years of experience in prototyping and manufacturing for the automation industry, Mastars combines advanced rapid prototyping with digital manufacturing to deliver high‑performance prototypes and production‑ready components. From concept validation to industrialization, we support the full cycle—DFM, rapid iteration, tooling, and seamless transition from pilot to high‑volume production—ensuring design intent translates into reliable, manufacturable products on time and on budget.

Focused on the automated production of industrial components, we serve everything from simple automatic parts to complex automation systems. Our engineering and quality teams apply GD&T, CMM inspection, and SPC process control, reinforced by robotic integration and rigorous EOL testing, to provide stable, traceable, and repeatable results across builds. With an end‑to‑end supply chain that spans plastics, metals, electronics, and testing, we coordinate cost, quality, and lead time to help you accelerate time‑to‑market while de‑risking scale‑up. Typical outcomes for qualified programs include up to 10% cost reduction, annual volumes around 10,000 units, and initial lead times near 30 days from NPI to first mass production.

Automation Parts Mastars Serves

Materials for Automation Applications

✔️Metals and magnetic materials:

Steel, aluminum alloy, copper and copper alloys, stainless steel, rare‑earth permanent magnets (NdFeB), soft magnetic materials (ferrite, SMC), cast iron

✔️Engineering plastics and elastomers:

POM, PA (nylon), PC, ABS, PP, PMMA (acrylic), PTFE (Teflon), phenolic (bakelite), silicone, polyurethane (PU)

✔️Electronics and functional materials:

ICs, power semiconductors (IGBT, MOSFET), sensors, optoelectronic devices, semiconductor silicon wafers, PCB substrates, insulation materials, magnet wires/enameled wires, power/signal cables, glass, ceramics

Top Precision Automation Applications

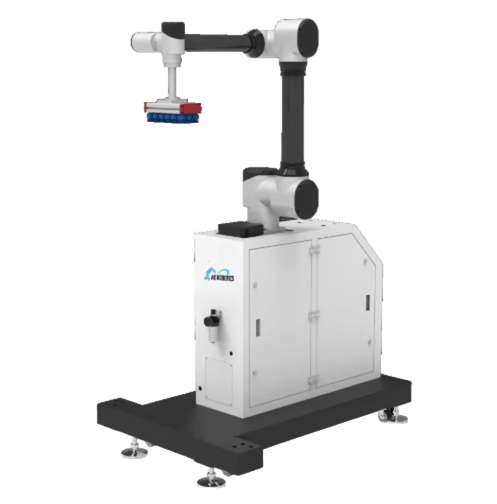

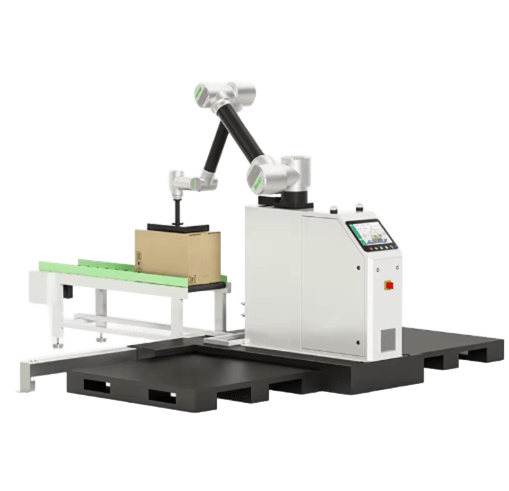

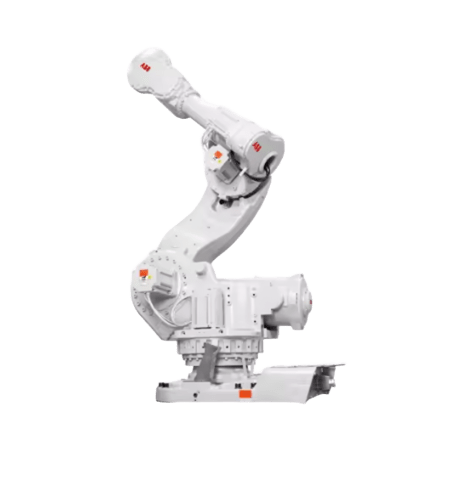

✔️ Robot prototypes and parts

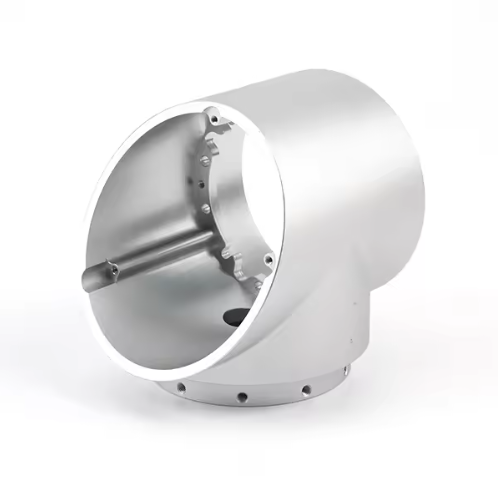

Prototype robot including precision robot arm joints, transmission parts, end effectors, etc. These parts usually require precise tolerances and complex geometries.

✔️ Components of automated mechanical equipment

Transmission parts: ball screws, guide rails, sliders, nut seats, support seats, couplings.

Linear motion parts: guide shafts, shaft supports, linear bearings/ball bushings, linear guides, ball screws, screw support seats, trapezoidal screws.

Mechanical custom parts: bearings, seat bearings, retaining rings, springs, fasteners, plungers, positioning parts, operating parts, nitrogen springs, quick clamps, locating pins, precision bushings.

Housings and brackets: metal/plastic enclosures and supports for electrical and control system components.

✔️ UAV parts

UAVs are widely used in automation, and their rapid prototyping covers propellers, frame structures, and motor brackets.

✔️ Components of automated control systems

PLC controller housings, circuit boards, and interface modules—rapid prototyping enables fast iteration and electronic performance validation.

Why Choose Mastars

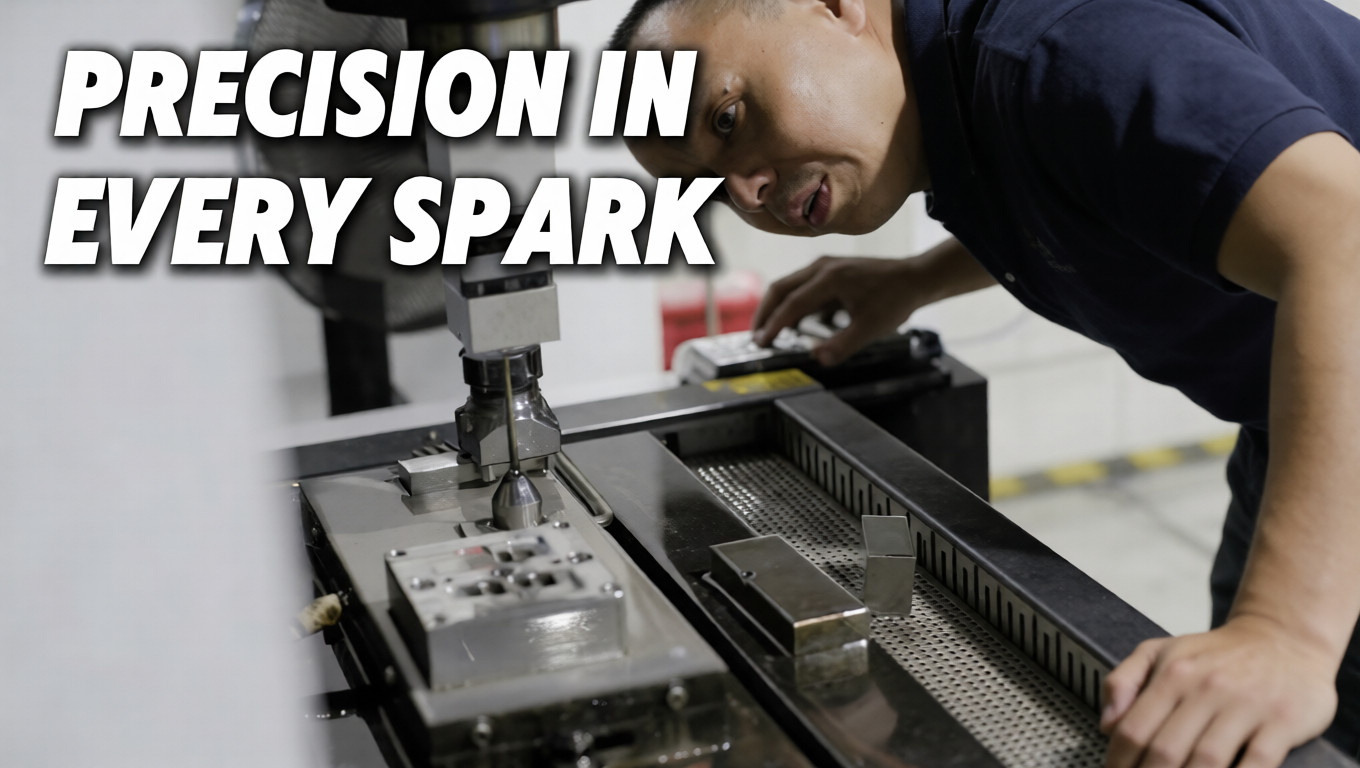

✔️Strong Manufacturing Capabilities

With ISO IATF certification, Mastars delivers communication parts that meet exact dimensions, structural integrity, and performance standards.

✔️Get Instant Quotation

Upload CAD to receive instant communication part quotes and start production immediately. Take control with real‑time order tracking and management.

✔️ Tight Tolerance Communication Parts

Tight‑tolerance CNC to ±0.001 in; supports complex custom parts.

✔️ Fast Cycle Time

Mastars delivers quotes in minutes and parts in days, cutting cycle times by up to 50%; our advanced technologies and extensive technical experience ensure high‑quality communication aerospace parts with faster lead times.

Automation Products Post-Processing Capabilities

✔️ Anodizing

✔️ Passivization

✔️ Electroplating

✔️ Powder Coating

✔️ Insert Installation

✔️ Heat Treatment

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.