5-Axis CNC Machining

with Mastars

Our 5-axis CNC machining delivers high-precision, intricate parts with complex geometries, tolerances down to 0.01mm. Get instant online quotes.

5 Axis Machining with Mastars

Mastars’ 5-axis machining services deliver unrivaled speed and flexibility. Armed with a full range of advanced 5-axis CNC machines and extensive material options, Mastars is capable of producing top-tier 5-axis machined parts.

Our experienced team and robust manufacturing capacity enable rapid design and fabrication of complex, time-sensitive components. Leveraging world-class equipment and proven expertise, Mastars adopts optimized setups to deliver precise, intricate parts.

5-Axis CNC Machining Products

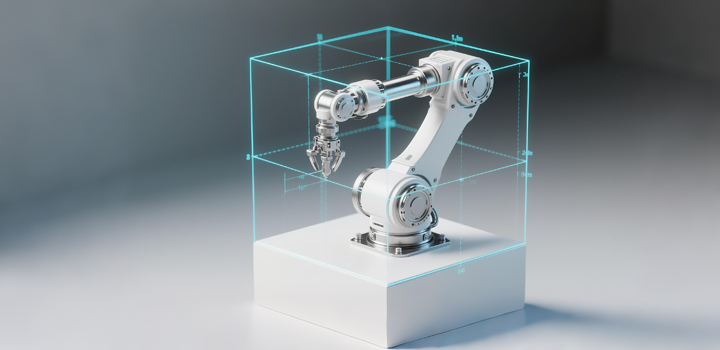

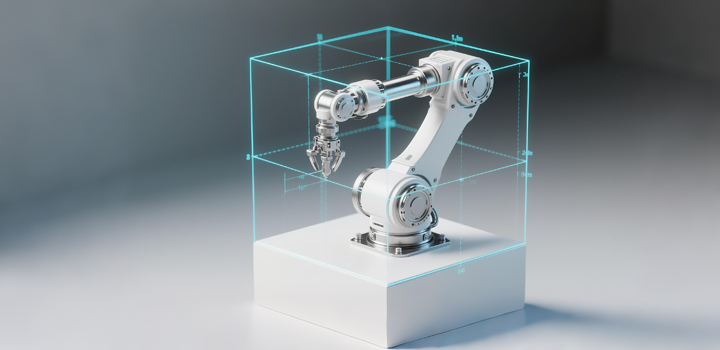

What is 5-axis Machining?

5-axis CNC machining is an advanced manufacturing process that enables cutting tools to move simultaneously across five axes. This capability efficiently produces complex, high-precision parts while minimizing the number of production setups.

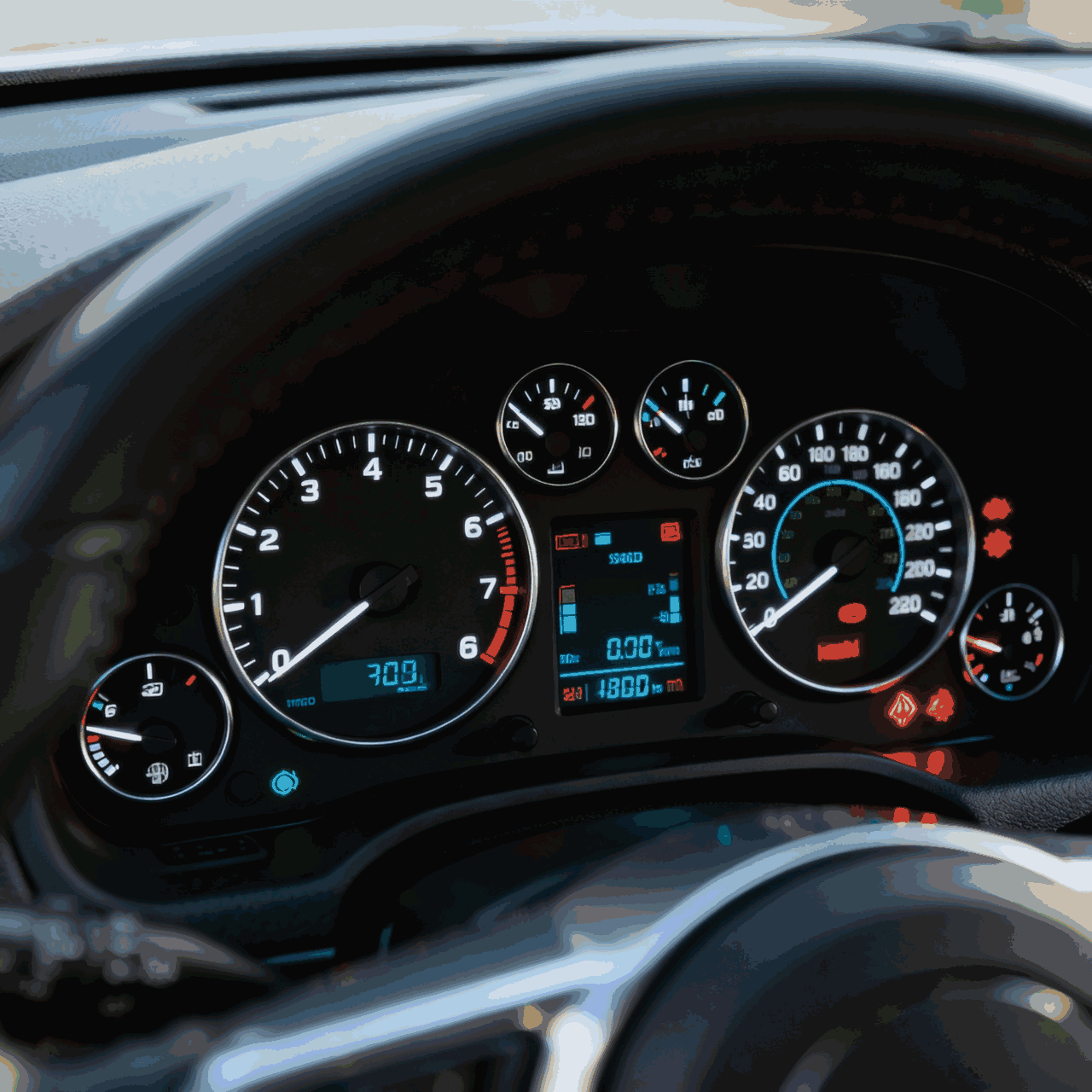

Industries including aerospace, automotive and medical device manufacturing depend on 5-axis machining services to fabricate intricate components requiring extreme accuracy.

5-axis VS. 3-axis Machining

CNC machining capacity hinges on choosing 3-axis or 5-axis systems. 3-axis (X/Y/Z) is efficient and low-cost, ideal for simple flat-surface parts, widely used in automotive, construction and aerospace industries.

5-axis adds two rotational axes for multi-angle cutting, perfect for intricate, high-precision components in aerospace, medical and advanced automotive fields. Though with higher upfront costs, it cuts setup times and human error—3-axis suits basic designs, while 5-axis excels at complex, tight-tolerance parts.

Materials for Custom 5-axis CNC Machining

| Metal | Plastic | |||

| Aluminum | Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380) | ABS | ABS Beige(Natural), ABS Black, ABS Black Antistatic, ABS Milky White, ABS+PC Black, ABS+PC White | |

| Copper | Copper C101(T2), Copper C103(T1), Copper C103(TU2), Copper C110(TU0), Beryllium Copper | PC | PC Black, PC Transparent, PC White, PC Yellowish White, PC+GF30 Black | |

| Brass | Brass C27400, Brass C28000, Brass C36000 | PMMA (Acrylic) | PMMA Black, PMMA Transparent, PMMA White | |

| Bronze | Tin Bronze | POM | POM Black, POM Blue, POM White | |

| Steel | Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC | PA (Nylon) | PA(Nylon) Blue, PA6 (Nylon)+GF15 Black, PA6 (Nylon)+GF30 Black, PA66 (Nylon) Beige(Natural), PA66 (Nylon) Black | |

| Stainless steel | Stainless Steel SUS201, Stainless Steel SUS303, Stainless Steel SUS 304, Stainless Steel SUS316, Stainless Steel SUS316L, Stainless Steel SUS420, Stainless Steel SUS430, Stainless Steel SUS431, Stainless Steel SUS440C, Stainless Steel SUS630/17-4PH,Stainless Steel AISI 304 | PE | PE Black, PE White | |

| Magnesium | Magnesium Alloy AZ31B, Magnesium Alloy AZ91D | PEEK | PEEK Beige(Natural), PEEK Black | |

| Titanium | Titanium Alloy TA1, Titanium Alloy TA2, Titanium Alloy TC4/Ti-6Al 4V | PP | PP Black, PP White, PP+GF30 Black | |

| HDPE HIPS LDPE PBT PPA | HDPE Black, HDPE White, HIPS Board White, LDPE White, PBT Black, PBT Milky White(Natural) | |||

| PAI PET PPS PS PVC | PAI Brown,PET Black, PET White, PET+GF30 Black, PET+GF30 White, PPS Black, PPS White, PPS+GF30 Black, PPS+GF30 White, PS Transparent, PVC Grey | |||

| PTFE (Teflon) UPE Bakelite FR-4 | Teflon (PTFE) Black, Teflon (PTFE) White, UPE Black, UPE White, Bakelite Black, Bakelite Orange, FR-4 Aqua Green, FR-4 Yellow | |||

Applications of 5-Axis CNC Machining Service

Applications

Surface Finishes for 5 Axis CNC Machining

| Type | Material | ||

| As Machined | As-machined finish is the direct CNC-machined surface—cost-effective, with visible tool marks. | ||

| Anodizing | Anodizing boosts aluminum parts’ corrosion and wear resistance, and enables color dyeing. | ||

| Polishing | Polishing creates a high-gloss finish, reducing metal surface roughness and boosting aesthetic appeal. | ||

| Sand Blasting | Sand blasting uses pressurized sand or media to clean and texture surfaces, creating a uniform matte finish. | ||

| Tumbling | Tumbling smooths and polishes small parts via barrel friction and abrasion, yielding a consistent, slightly textured finish. | ||

| Electropolish | Electropolishing is a chemical process that smooths, brightens surfaces and enhances corrosion resistance. | ||

| Alodine | Alodine coating delivers corrosion protection and enhanced paint adhesion, ideal primarily for aluminum surfaces. | ||

| Heat Treatment | Heat treatment modifies metal’s mechanical properties to boost hardness, strength or ductility. | ||

| Brushed Finish | Brushed finish delivers a unidirectional satin texture, minimizing the visibility of surface marks and scratches. | ||

| Powder Coating | Powder coating delivers a thick, wear-resistant layer with versatile color and texture options, suitable for diverse surfaces. | ||

| Electroplating | Electroplating deposits a thin metal layer on parts, enhancing wear resistance, corrosion resistance and surface conductivity. | ||

| Black Oxidize | Black oxide is a conversion coating for ferrous metals, boosting corrosion resistance and reducing light reflection. | ||

5-Axis CNC Machining Capabilities

| Type | Description | ||

| Maximum Part Size | 4000×1500×600 mm | ||

| Minimum Part Size | 5 x 5 x 5 mm | ||

| General Tolerances | Within ±0.002 mm | ||

| Lead Time | For standard operations, lead times can be as short as 2-3 days, while more complex projects might require up to 2 weeks. | ||

5 Axis CNC Machining Design Guidelines

| Recommended Size | |||

| Minimum Feature Size | Minimum feature size should be no less than 0.5 mm in width or depth to ensure structural integrity. | ||

| Linear Dimension | Maintain a precision within ±0.005 mm for linear dimensions to ensure accuracy across the machined part. | ||

| Hole Diameters (not reamed) | Holes can be machined with diameters starting from 1 mm up to 40 mm without reaming for precision sizing. | ||

| Shaft Diameters | Shaft diameters should range from 2 mm to 300 mm, considering the tool accessibility and torque requirements. | ||

| Threads and Tapped Holes | Threads from M2 to M24 can be machined. Ensure to provide adequate relief at the bottom of tapped holes. | ||

| Text | Minimum text height of 1.5 mm with a depth of 0.5 mm for clarity after machining. | ||

Mastars 5-axis Machine WorkShop

The Whole CNC Machining Services We Provide

We offer comprehensive precision CNC machining services, including milling, turning, and surface grinding. Whether you need high-volume production or low-volume prototype iterations, we support flexible development with fast turnaround and consistent quality. Our CNC turning and milling processes are tailored to produce a wide range of components—from jigs and fixtures to parts featuring cylinders, holes, slots, and grooves.

CNC milling service

We offers a range of CNC milling processes to produce precise and complex parts with high-dimensional tolerances:

> Carving machine

> CNC three-axis

> CNC four-axis

> CNC five-axis

> Milling machine / End milling / Gantry milling

CNC turning service

Grinding machining

EDM (Electrical Discharge Machining)

> Its machining accuracy is high.

> Get a very good surface finish.

> Any material can be machined, regardless of its hardness.

> Moulds and parts with complex shaped holes and cavities can be processed.

> It is suitable for machining deep and fine holes, curved surfaces, special-shaped holes, deep grooves, narrow slits and thin walls, etc.

> There is no physical contact between the tool and the workpiece, and the damage to the workpiece is small.

> Suitable for machining precision injection molds.

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.