Custom Automotive Molds

with Mastars

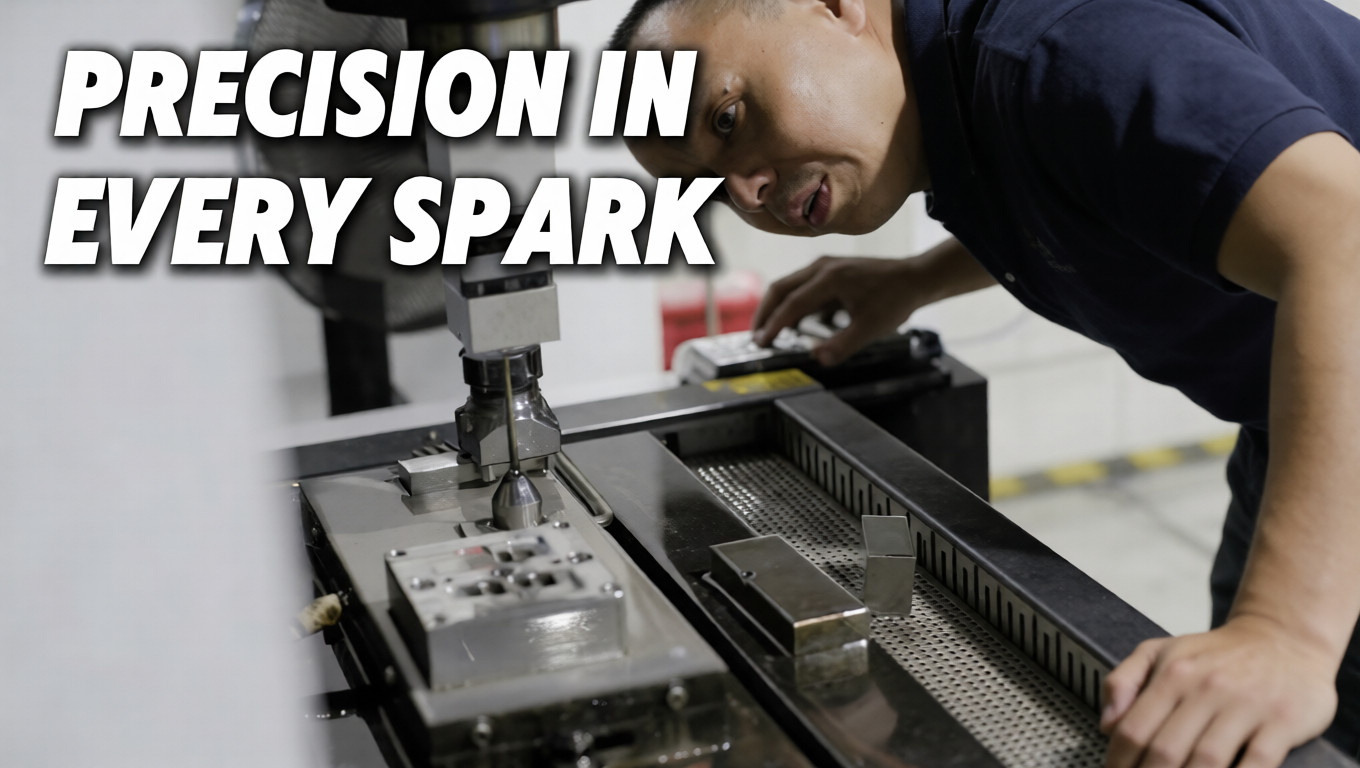

Precision Engineered Auto Molds for Streamlined Production

sets mold capacity per month

sets injection machines from 150T to 1000T

plastic parts capactiy per month

Part tolerances minimized to 0.02 mm

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.