In the realm of CNC Machining, 4-Axis Machining stands out as a pivotal advanced manufacturing technology that bridges the gap between 3-Axis Machining’s simplicity and 5-Axis Machining’s complexity. Unlike 3-Axis Machining, which restricts tool movement to the X, Y, and Z linear axes, 4-Axis Machining incorporates a rotational axis—typically the A-axis (rotating around the X-axis) or B-axis (rotating around the Y-axis)—to enable multi-angle cutting, continuous contouring, and enhanced access to complex geometries. This rotational capability, combined with the precision of Computer Numerical Control (CNC) systems, makes 4-Axis Machining indispensable in industries requiring high-precision, intricate components, where traditional machining methods fail to deliver consistency, efficiency, or dimensional accuracy. Below are detailed application cases across key industries, supplemented by core professional terms to illustrate the technology’s practical value and technical nuances.

1. Application in Aerospace Components: Turbine Blades and Engine Brackets

The aerospace industry demands components that adhere to stringent tolerances (often ±0.0005 inches), exhibit exceptional material integrity, and withstand extreme temperatures and mechanical stress—requirements that 4-Axis Machining fulfills seamlessly. A prime example is the manufacturing ofturbine blades for commercial jet engines, where the technology addresses the challenges of machining complex airfoil profiles, root fillets, and cooling channels.

Turbine blades are typically fabricated from high-performance alloys such as Inconel 718 or titanium alloys (Ti-6Al-4V), materials known for their high strength-to-weight ratios but poor machinability due to their hardness and tendency to cause tool wear. 4-Axis CNC Machining centers equipped with high-speed spindles (15,000–30,000 RPM), indexable carbide inserts, and adaptive control systems (ACS) are used to tackle these materials. The rotational A-axis allows the blade blank to be tilted incrementally, enabling the cutting tool to access the curved airfoil surface from multiple angles without repositioning the workpiece—a process known as continuous 4-axis contouring. This eliminates the need for multiple setups, reducing setup time by 30–40% compared to 3-Axis Machining and minimizing the risk of positional error caused by repeated clamping.

Another aerospace application is the production of engine mounting brackets, which feature complex pockets, chamfers, and angled holes that must align with other engine components. 4-Axis Machining uses CNC G-code programming (specifically G04 dwell commands and G91 incremental positioning) to control the rotational axis, ensuring that angled holes are drilled perpendicular to the bracket’s surface—critical for load distribution and structural integrity. Additionally,tool length compensation (TLC) and work offset compensation (G54–G59) are employed to correct for minor variations in tool wear and workpiece positioning, maintaining tolerances within aerospace standards.

2. Application in Medical Devices: Orthopedic Implants and Surgical Instruments

The medical device industry relies on 4-Axis Machining for the production of custom orthopedic implants and precision surgical instruments, where biocompatibility, dimensional accuracy, and surface finish are non-negotiable. Orthopedic implants—such as hip stems, knee femoral components, and spinal screws—require complex geometries that conform to the patient’s anatomy, making 4-Axis Machining an ideal solution.

Hip stems, for instance, are machined from biocompatible materials like cobalt-chromium (Co-Cr) alloys or medical-grade titanium. The stem features a tapered shaft with a rough surface texture (to promote osseointegration) and a threaded proximal end (to attach to the hip ball component). 4-Axis Machining usesface milling and end milling withball-nose end mills to create the tapered shaft, while the rotational B-axis allows for the machining of the threaded section at an angle—eliminating the need for secondary operations. CNC adaptive machining is also used to adjust cutting parameters (feed rate, spindle speed, depth of cut) in real time, based on feedback from in-process monitoring sensors, ensuring consistent surface finish (Ra ≤ 0.2 μm) and preventing tool chatter.

Precision surgical instruments, such as laparoscopic forceps and orthopedic drills, also benefit from 4-Axis Machining. Laparoscopic forceps require thin, curved jaws with serrated edges for gripping tissue, and 4-Axis Machining enables the machining of these curved features in a single setup using contour milling. The rotational axis allows the tool to follow the jaw’s curve without reorienting the workpiece, reducing cycle time and improving dimensional consistency. Additionally, EDM (Electrical Discharge Machining) is often combined with 4-Axis CNC Machining for finishing tight tolerances on instrument tips, though 4-Axis Machining handles the majority of the roughing and semi-finishing operations.

3. Application in Automotive Performance Parts: Gearboxes and Suspension Components

In the automotive industry, particularly for high-performance and racing vehicles, 4-Axis Machining is used to produce gearboxes, suspension components, and intake manifolds—parts that require enhanced strength, precision, and performance. Gearboxes, for example, rely on helical gears and bevel gears that transmit power efficiently while minimizing noise and vibration, and 4-Axis Machining is critical for machining their complex tooth profiles.

Helical gears feature angled teeth that mesh smoothly, and their machining requires precise control of the tool’s angle relative to the gear blank. 4-Axis CNC Machining centers use the rotational A-axis to tilt the gear blank, allowing the hobbing tool or gear milling cutter to cut the helical teeth at the correct helix angle (typically 15–30 degrees). CNC interpolation (linear, circular, and helical interpolation) ensures that the tool moves in a coordinated manner with the rotational axis, creating uniform tooth profiles with tight tolerances (±0.001 inches). This process is far more efficient than traditional gear cutting methods, as it eliminates the need for dedicated gear-cutting machines and reduces lead time for prototype and production runs.

Suspension components, such as control arms and knuckles, also leverage 4-Axis Machining for their complex geometries. Control arms feature multiple angled bushings and mounting points that must align with the vehicle’s chassis, and 4-Axis Machining enables the machining of these features in a single setup using drilling, tapping, and milling operations. The rotational axis allows the tool to access hard-to-reach areas, such as the inner surfaces of the control arm, without requiring the workpiece to be flipped or re-clamped. This not only improves efficiency but also reduces the risk of geometric deviation caused by multiple setups.

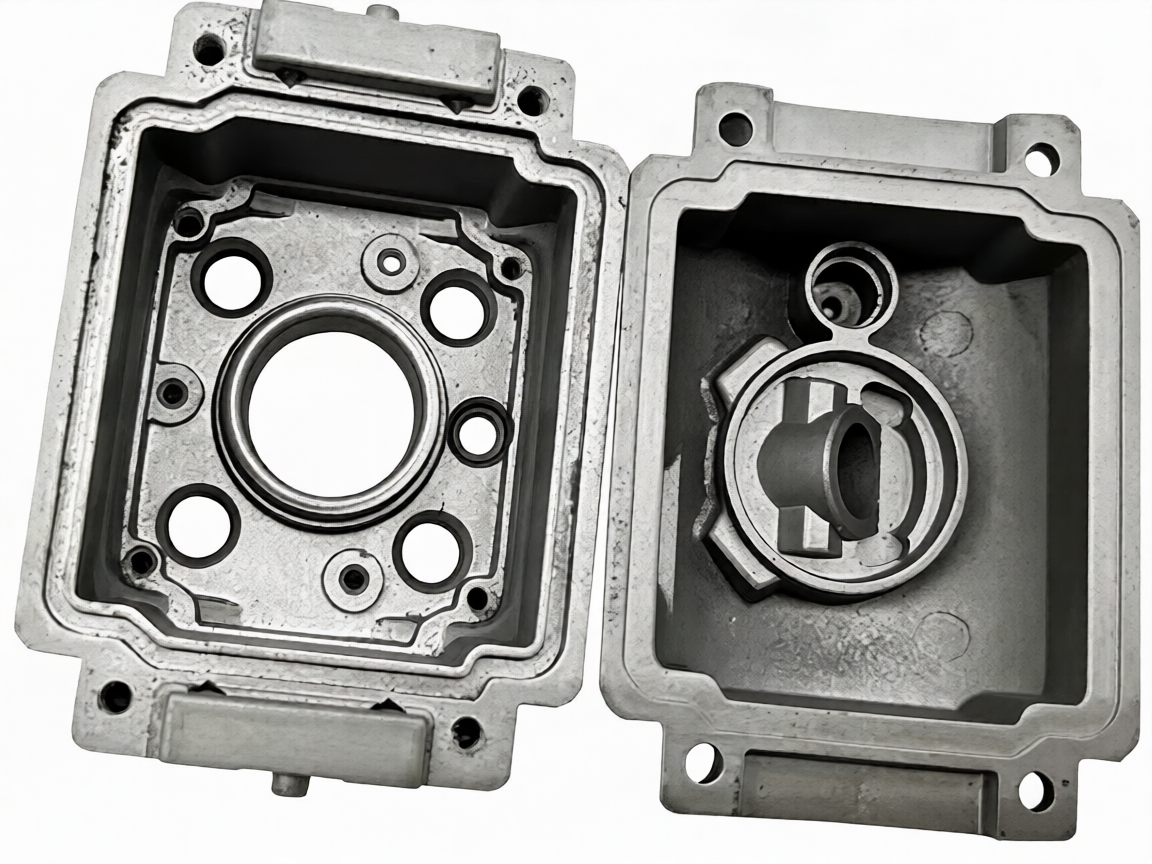

4. Application in Mold and Die Manufacturing: Cavity Inserts and Core Pins

Mold and die manufacturing requires the production of complex cavity inserts, core pins, and mold bases that define the shape of injection-molded or die-cast parts. These components often feature undercuts, curved surfaces, and intricate details that are difficult to machine with 3-Axis Machining, making 4-Axis Machining a preferred solution.

Cavity inserts for plastic injection molds, for example, often have curved inner surfaces and undercuts that require the tool to reach at multiple angles. 4-Axis Machining uses the rotational axis to tilt the cavity insert, allowing the end mill or ball-nose mill to machine the undercut features without collision with the mold body. Tool path optimization software (such as Mastercam or SolidWorks CAM) is used to generate efficient, collision-free tool paths that maximize material removal rate while maintaining surface finish. Additionally, high-feed milling (HFM) is employed to reduce cycle time for roughing operations, while finish milling with small-diameter tools ensures that intricate details are reproduced accurately.

Core pins, which form the internal features of molded parts, also benefit from 4-Axis Machining. Core pins often have threaded sections, grooves, or tapered surfaces that require precise machining at angles. The rotational axis allows the core pin to be rotated incrementally, enabling the tool to machine these features in a single setup. CNC threading cycles (G32, G92) are used to produce accurate threads, while grooving cycles (G75) create uniform grooves—critical for ensuring that the molded part can be easily ejected from the mold.

Key Technical Advantages of 4-Axis Machining in Product Manufacturing

Across all these applications, 4-Axis Machining offers distinct advantages over traditional machining methods, driven by its integration with CNC technology:

• Reduced Setup Time: By enabling multi-angle machining in a single setup, 4-Axis Machining eliminates the need for multiple clamping operations, reducing setup time by 30–50% and minimizing positional errors.

• Enhanced Geometric Capability: The rotational axis allows access to complex geometries (undercuts, curved surfaces, angled features) that are impossible or impractical to machine with 3-Axis Machining.

• Improved Precision and Consistency: CNC control systems, combined with compensation technologies (tool length, work offset, backlash compensation), ensure that components meet tight tolerances consistently, even for high-volume production.

• Increased Efficiency: Adaptive control, high-speed machining, and optimized tool paths reduce cycle time, while the elimination of secondary operations lowers production costs.

Conclusion

4-Axis Machining has emerged as a cornerstone of modern precision manufacturing, enabling the production of complex, high-tolerance components across aerospace, medical, automotive, and mold/die industries. Its integration with CNC Machining technologies—such as high-speed spindles, adaptive control, and advanced programming software—empowers manufacturers to overcome the limitations of traditional machining, delivering components that meet the most stringent industry standards. As product designs become increasingly complex and performance requirements continue to rise, 4-Axis Machining will remain a critical technology, driving innovation and efficiency in precision manufacturing. From turbine blades that power jet engines to orthopedic implants that improve patient outcomes, 4-Axis Machining proves its value as a versatile, reliable, and indispensable tool in the CNC Machining landscape.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.