Bridging Design and Manufacturing for Accelerated, De-risked Outcomes

Achieving your ultimate product goals requires a seamless transition from design to production. Our comprehensive suite of Design for Excellence (DfX) services is precisely engineered to bridge this gap, enabling you to reach the market faster and with significantly reduced risk.

We partner directly with your team for a thorough review of product design readiness, evaluating critical factors such as performance, reliability, durability, and scalability. This collaborative review is deepened through structured technology exchange meetings and a detailed gap analysis. The outcome is a customized, consultative strategy that strategically applies our deep manufacturing expertise to your development process, ensuring your product is not just well-designed, but optimally designed for manufacture.

And if you have a product that’s already verified?

We partner with you to transform key design insights into an actionable roadmap for the future, ensuring that continuous improvement fuels genuine innovation at every stage of development. While numerous factors contribute to making a product intuitive and easy to use, we are also here to ensure that its design is equally optimized for efficient and reliable manufacturability.

Large and diversified supply chain

At the heart of long-term product success lies strategic design, where we provide comprehensive guidance across manufacturability, cost, reliability, and testing to ensure your product is designed for cost-effective, scalable production. By integrating methodologies like Design for Manufacturing (DFM) early in the development process, we help identify and eliminate potential issues related to solderability, component placement, and assembly, thereby reducing costs and streamlining time-to-market. Our support extends through product validation, test development, and value analysis engineering, ensuring a robust, production-ready outcome that balances performance, quality, and economic efficiency from concept to volume manufacturing.

Learn how to select the best manufacturing process and material for your custom ...

Learn how to select the best manufacturing process and material for your custom ...

Learn how to select the best manufacturing process and material for your custom ...

Mitigation strategies

Adopting a holistic DfX methodology minimizes unforeseen challenges during the transition from design to manufacturing. Our tooling verification capabilities enable the early identification and resolution of potential quality issues with molds and tooling. Furthermore, we integrate Design for Cost (DfC) principles to prioritize your budget objectives and utilize Computer-Aided Design (CAD) file conversion to ensure you receive practical, workable design files.

How we do this

We have turned the smart factory from a concept into an operational reality through the strategic implementation of standards and a suite of internally developed automation systems, including our Digital Design for Automation Line, Digital Use Case Catalogs, and Internal Quotation Tool (IQT).

Design for Manufacturing (DfM)

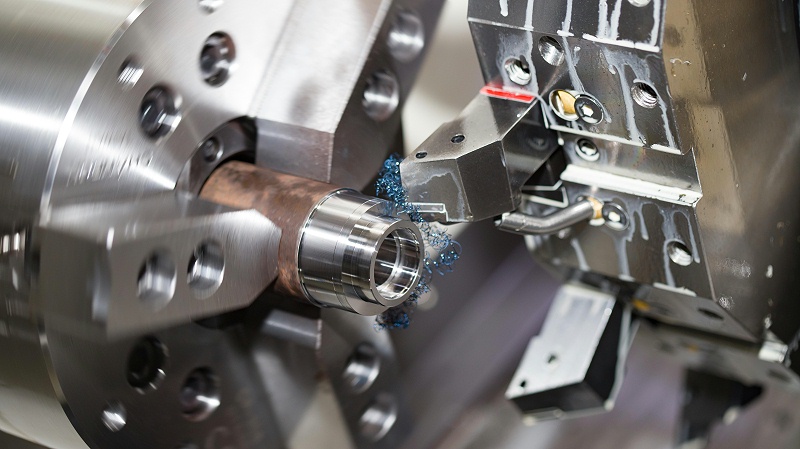

We ensure your product design is scalable by identifying both opportunities and unforeseen challenges in the manufacturing process. Our Design for Manufacturing (DfM) guidance focuses on enhancing product performance, increasing customizability, and reducing component counts—all while lowering non-recurring expenses. This approach allows you to maximize investment returns, accelerate time-to-market, and avoid costly design-related disruptions during full-scale production.

Through detailed DfM analysis, we implement key design adjustments that eliminate production waste and bottlenecks while maximizing product performance. We prepare your design to incorporate the most cost-effective and efficient available processes, supported by robust materials management and quality control systems.

Our evaluation extends to the individual part level using Design for Manufacturing and Assembly (DFMA) principles. This method reduces the number of components and assembly steps required, leading to more consistent build quality and greater manufacturing efficiency.

Design for Testing (DfT)

Our Design for Reliability (DfR) methodology ensures your product performs as intended throughout its lifespan by proactively identifying and mitigating potential failures during the design phase, long before physical prototyping . This approach integrates reliability considerations directly into the product development cycle, utilizing predictive engineering analyses to significantly reduce the risk of field failures, lower warranty costs, and accelerate time-to-market.

We employ advanced Finite Element Analysis (FEA) to simulate your product's real-world performance under various structural, thermal, and dynamic loads.This virtual validation allows for rapid exploration of design alternatives to optimize durability and performance, ensuring issues are resolved early when changes are most cost-effective.

Furthermore, our Design for Testability (DFT) strategies are implemented to guarantee efficient and comprehensive manufacturing testing.By incorporating test structures like scan chains and built-in self-test (BIST), we enable high fault coverage during production, ensuring every unit shipped meets your quality standards and reducing the need for costly post-production debugging.

Design for Automation

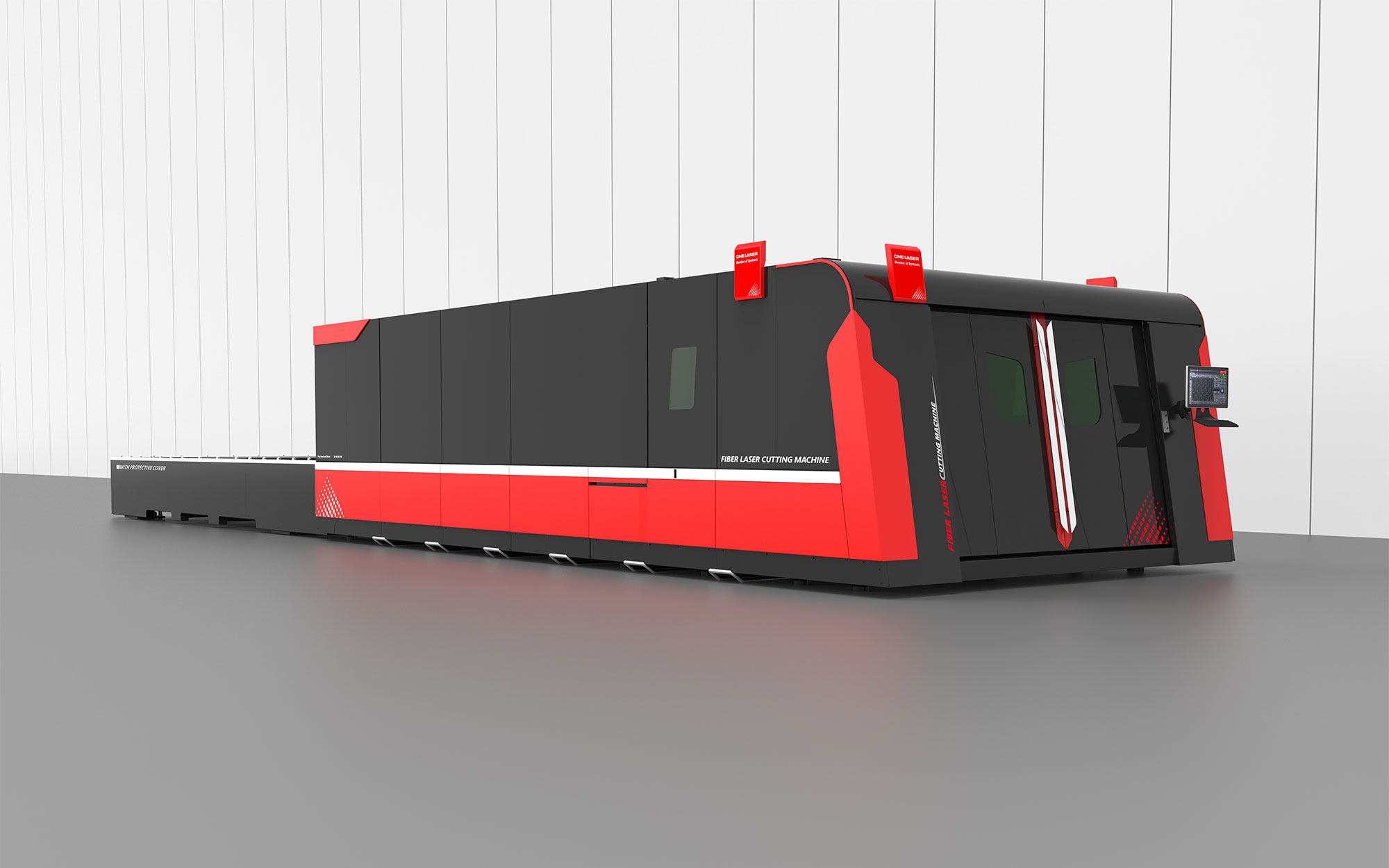

We accelerate your transition to automated manufacturing with digitized simulation tools that save time and improve accuracy.

Our integrated digital solutions for automation help you accelerate time-to-market, whether launching in a new region or scaling to meet quality and production goals. These capabilities enable your team to optimize product designs and validate manufacturing lines for automated production success.

Using centralized digital tools like Digital Design for Automation and Digital Design for Automation Line, we significantly shorten product validation time and enable virtual conceptualization of automated assembly processes.

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.