Sheet Metal Fabrication

with Mastars

Sheet metal components & assemblies in as fast as 1 day

—get an online quote today for your prototype or low-volume project.

Sheet Metal Fabrication Capabilities

Mastars is one of the toppest companies in the world which offer sheet metal prototyping services. Fitted with the latest cutting edge technology, we are ready and equipped for nearly any task required by our customers. Whether you are looking for production intent sheet metal parts or one-off, mock-up style for fit & function, Mastars is your one-stop shop for prototypes, assemblies and short-run services.

Our team of highly skilled toolmakers, designers and technicians work seamlessly to provide the highest level of quality. With each piece, we assess for precise tolerances and requirements that challenge the best in the industry.

Sheet Metal Fabrication Products

Equipments

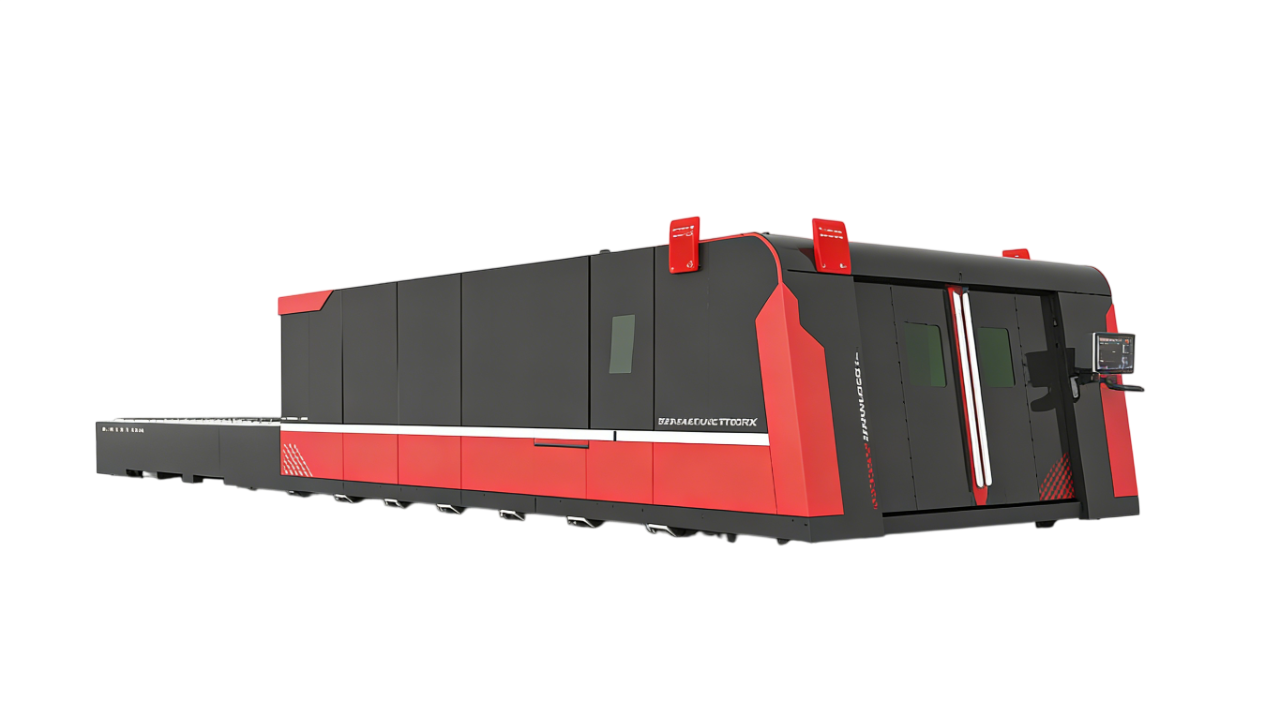

Fiber Laser Cutting Machine

Byström (Swiss) Laser Power: 6000-12000W

Processing Area (L×W): 12000×3200mm

Flat Cutting Thickness: Stainless steel, carbon steel, aluminum, and other metal sheets 0.5-50mm

Long-term stable batch cutting of medium and heavy plates over 20mm thick, with extreme cutting capabilities for ultra-thick plates over 50mm thick

Length can be customized according to user processing requirements; Wide range of processed materials, including sheet metal and large-sized steel sections.

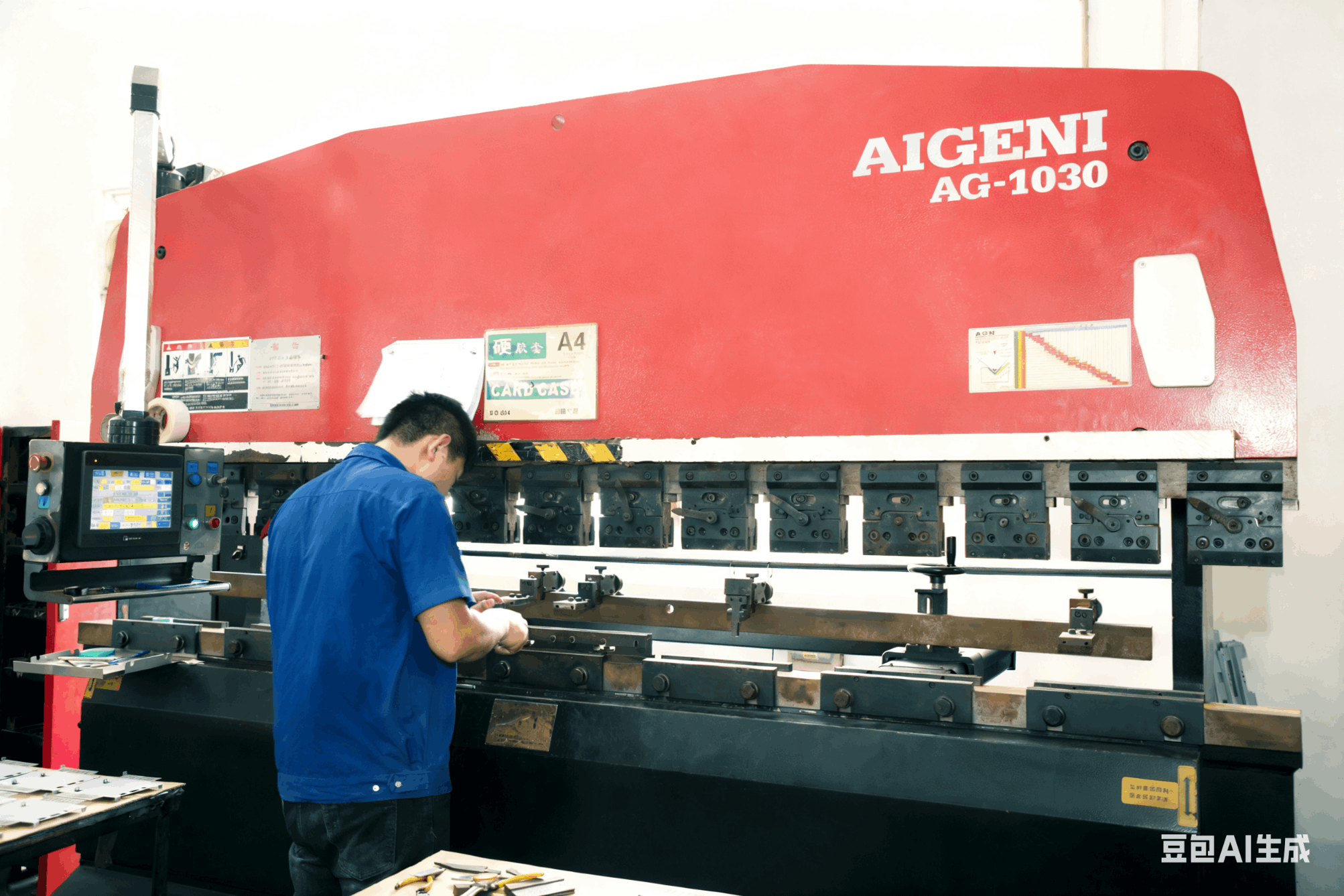

Stamping Machine

We possess 22 punch presses from Gu'anli and Jin'aolan, with pressure ranging from 60T to 500T

This includes the Jin'aolan ALE-500 closed-type double-crankshaft high-precision steel frame punch press

Punch press capacity: 500T

Maximum die height: 600mm

Slide stroke: 300mm

SLS (Selective Laser Sintering)

Example Plaforms In Production Include:

EOS P396 Build Volume: 340 x 340 x 600 mm

EOS/Integra P400 Build Volume: 400 x 400 x 400 mm

Farsoon HT1001P Build Volume: 1000 x 500 x 450 mm

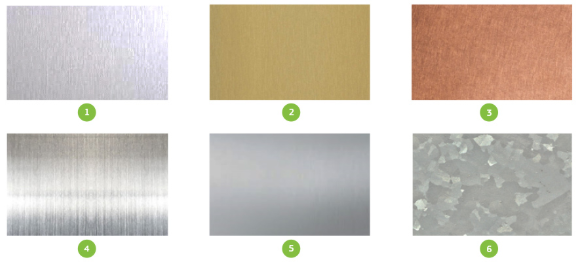

Material Options

✔️(1) Aluminum

✔️(2) Brass

✔️(3) Copper

✔️(4) Stainless Steel

✔️(5) Steel: CR Non-treated

✔️(6) Steel: CR Galvanneal and CR Galvanized

Sheet Metal Applications

Sheet metal fabrication is a versatile process for metal components, supporting both high-volume commodity production and low-volume custom applications. Common sheet metal parts include:

✔️Electrical enclosure

✔️ Parts for computer electronics

✔️Chassis

✔️Brackets

✔️Cabinets

✔️Mounts

✔️Appliances

Advantages of Mastars' Sheet Metal Services

➀ Highly Efficient and Convenient Operation

Sheet metal prototyping is simple and efficient, improving prototyping efficiency and ensuring all customer needs are met.

➁ High Precision, Reduced Production Costs

Providing efficient and professional sheet metal prototyping helps companies save significant mold-making costs and production time.

➂ Simplified Production Process:

Sheet metal prototypes simplify the equipment production process, saving time for both companies and customers, and ensuring the finished product meets customer requirements.

➃ Strong Material Adaptability

Sheet metal processing has a high power density, allowing for the processing of even high-melting-point, high-hardness, and brittle materials.

➄ Easy to Control

Sheet metal processing can be easily combined with precision mechanics, precision measurement technology, and computers to achieve a high degree of automation and high processing accuracy.

➅ Convenient and Flexible

Robots can be used in sheet metal processing in harsh environments or places inaccessible to others.

➆ Wide Range of Applications

The divergence angle of the beam in sheet metal processing can be less than 1 milliradian, the spot diameter can be as small as micrometers, and the action time can be as short as nanoseconds and picoseconds.

Core competencies of Mastars' Sheet Metal Service

✔️ Sheet Metal Stamping & Forming

✔️ 5-Axis Laser Cutting

✔️ 3-Axis Laser Cutting

✔️ Manual TIG Welding

✔️ Manual MIG Welding

✔️ Comprehensive CNC Machining

✔️ CMM Measurement

✔️ Surface Treatment Processes

Our Ideas Have Helped Clients Bring Hundreds Of Products To Market

How Does Sheet Metal Fabrication Work?

Thin-gauge sheet metal is secured on a flat bed. A laser cutter precisely cuts programmed profiles (minimizing heat damage), while a punch adds holes, slots, or tabs per geometric needs.

Post-cutting, parts are deburred to eliminate sharp edges. A press brake bends blanks to final 3D shapes with tight tolerances, followed by secondary finishing (welding, hardware insertion, coating).

Our Sheet Metal Fabrication Process

Unlike traditional sheet metal shops, we provide unlimited capacity and a user-friendly online quoting system for on-time delivery—from 1 to 500 parts. Our expert engineers optimize designs, and accessible online resources support you; our one-stop local service (prototypes, assemblies, finishing) cuts production time and speeds up product launches.

Advantages of Sheet Metal Fabrication

Precision sheet metal fabrication is perfect for metal components—flexibly catering to both prototyping needs and full-scale production orders.

✔️Low material waste

✔️Can cost-effectively scale to production volumes

✔️Multiple finishing options like anodizing and powder coating

Quality Control and Materials Management

✔️ High-Quality Raw Materials

Selected stainless steel, aluminum, non-ferrous metals and various alloys. With sufficient and abundant raw material supply, we can fully meet customer requirements for raw materials and achieve rapid material preparation, balancing quality and efficiency.

✔️ Customization Experience

We can easily adapt to diverse production requirements across multiple fields, manufacture more complex and high-precision sheet metal products, and provide professional advice on customers' raw material selection, design and production.

✔️ Quality Pursuit

Relying on advanced processing equipment and experienced operators to strictly control workpiece precision, our testing center is equipped with high-end and comprehensive testing instruments such as German GOM blue light 3D scanners, German Zeiss coordinate measuring machines, Swedish Hexagon coordinate measuring machines, 2.5D automatic vision measuring instruments, Hitachi handheld X-ray fluorescence spectrometers, Swiss TESA height gauges and Japanese Mitutoyo roughness testers, ensuring your products meet the designed precision and functional requirements.

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.