In the metal precision forming manufacturing industry, Hot Chamber Die Casting (also known as hot chamber die casting) has become the preferred process for mass production of low-melting-point metal components, relying on its core advantages of high efficiency, high automation, and excellent forming precision. It is widely used in various fields such as automotive, consumer electronics, medical devices, and hardware accessories, providing an efficient and economical forming solution for all types of small, precision, and complex metal components. Together with cold chamber die casting, it constitutes the two core process systems of the die casting industry, driving the development of metal forming technology towards refinement, high efficiency, and scale.

I. What is Hot Chamber Die Casting?

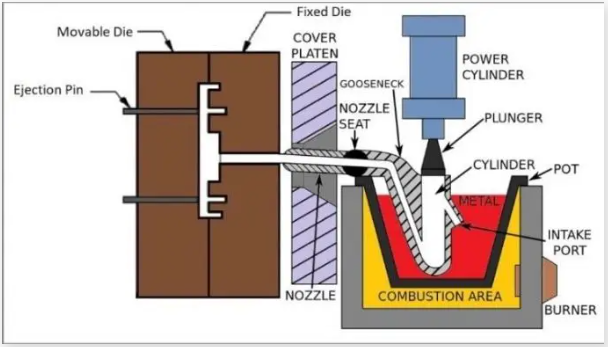

Hot Chamber Die Casting, literally translated as hot chamber die casting in Chinese, is a special metal die casting forming process. Its core feature is that the injection mechanism (including the injection chamber and injection plunger) is directly immersed in the molten metal liquid. Through the reciprocating movement of the injection plunger, the molten metal is directly injected into the closed mold cavity, and after rapid cooling and solidification, the mold is opened to take out the formed metal components.

The biggest difference from cold chamber die casting (where the injection mechanism is separated from the molten metal furnace, and molten metal needs to be scooped and injected into the injection chamber manually or mechanically) is that the injection chamber and furnace of hot chamber die casting are integrally designed. The molten metal is always in a molten heat preservation state, eliminating the need for additional scooping and transfer links. This fundamentally improves production efficiency, reduces heat loss and oxidation of the molten metal, and ensures the quality stability of the formed parts.

Simply put, hot chamber die casting is like "directly scooping soup from a boiling pot into a mold". The injection mechanism is immersed in the molten metal throughout the process to achieve "injection and forming immediately". It is especially suitable for metal materials with low melting points and good fluidity, such as zinc alloy, magnesium alloy, lead alloy, etc., and is an "efficient tool" for mass production of small precision metal parts.

II. Core Structure and Working Principle of Hot Chamber Die Casting

(I) Core Equipment Structure

The structure of the hot chamber die casting machine is relatively compact, mainly composed of four core components: furnace, injection mechanism, mold clamping mechanism, and control system. Each component works together to ensure stable and efficient operation of the process. The key structures are as follows:

• Furnace: As a storage and heat preservation device for molten metal, it is integrally connected to the injection chamber. A heating element (usually electric heating wire or gas heating) is installed inside, which can heat the metal material to a molten state and keep it warm at a set temperature (usually 380-600℃ depending on the material) to ensure that the molten metal always maintains good fluidity. The furnace material must have high temperature resistance and corrosion resistance, usually made of heat-resistant steel, and the inner wall will be coated with a heat preservation coating to reduce heat loss.

• Injection Mechanism: The core component, including the injection chamber, injection plunger, and nozzle, is directly immersed in the molten metal of the furnace. The injection chamber is a temporary storage and injection channel for molten metal, connected to the mold gate through a nozzle; the injection plunger is driven by a hydraulic system, which can realize rapid and stable reciprocating movement to inject the molten metal in the injection chamber into the mold cavity at high pressure; the nozzle is responsible for sealing the connection between the injection chamber and the mold to prevent molten metal leakage, and at the same time guide the molten metal to enter the cavity evenly.

• Mold Clamping Mechanism: Used to control the opening and closing of the mold, ensuring that the mold is tightly closed during the injection process to withstand the high-pressure impact of the molten metal (usually 10-50MPa). The mold clamping mechanism is hydraulically driven, with sufficient clamping force, and can adjust the mold clamping speed and pressure according to the mold size and forming requirements to avoid defects such as mold overflow and part flash.

• Control System: Controlled by PLC or industrial computer, it can accurately set and adjust key process parameters such as furnace temperature, injection speed, injection pressure, mold clamping speed, and cooling time to realize automatic production. High-end hot chamber die casting machines are also equipped with functions such as fault alarm, parameter monitoring, and production counting, which facilitate the management and maintenance of operators and improve production stability.

(II) Working Principle (Complete Process)

The working process of hot chamber die casting is simple and efficient, with a high degree of automation throughout, and no manual intervention in the transfer of molten metal. The core process can be divided into 6 steps, which cycle repeatedly to achieve mass production:

1. Metal Melting: Put low-melting-point metal raw materials (such as zinc alloy ingots) into the furnace, heat them to a molten state through heating elements, and keep them warm at a set temperature to ensure that the molten metal has good fluidity and no oxidized impurities;

2. Mold Clamping and Locking: The mold clamping mechanism drives the mold to close, applies sufficient clamping force to ensure that the mold cavity is completely sealed, which can withstand the subsequent high-pressure impact of the molten metal, and at the same time, the mold cooling system starts to work to cool the cavity;

3. Liquid Suction and Chamber Filling: The injection plunger moves upward, forming a negative pressure in the injection chamber. Under the action of atmospheric pressure, the molten metal enters the injection chamber through the liquid suction port at the bottom of the injection chamber to complete the filling of the injection chamber;

4. High-Pressure Injection: The injection plunger moves downward rapidly, injecting the molten metal in the injection chamber into the mold cavity at high pressure (10-50MPa) and high speed (1-5m/s). During the process, the molten metal quickly fills every corner of the cavity and discharges the air in the cavity;

5. Cooling and Solidification: The molten metal is rapidly cooled and solidified in the mold cavity (the cooling time is usually a few seconds to dozens of seconds, depending on the part thickness), forming a metal component consistent with the shape of the mold cavity;

6. Mold Opening and Part Taking: After cooling, the mold clamping mechanism drives the mold to open, the ejection mechanism ejects the formed metal component from the cavity, and the operator or automatic equipment takes the part to complete a production cycle, then enters the next cycle.

III. Process Characteristics of Hot Chamber Die Casting (Advantages and Limitations)

The process characteristics of hot chamber die casting are determined by its "integrated injection chamber and furnace" design. Compared with cold chamber die casting and other metal forming processes, it has significant advantages and certain application limitations, which need to be reasonably selected according to product requirements.

(I) Core Advantages

1. Extremely High Production Efficiency: The injection chamber and furnace are integrated, eliminating the need for manual or mechanical scooping and transfer of molten metal. The production cycle is short (each cycle only takes 5-30 seconds), and hundreds or even thousands of parts can be produced per hour, which is suitable for large-scale mass production and greatly reduces the production cost per unit product.

2. High Degree of Automation: The entire production process (mold clamping, liquid suction, injection, cooling, mold opening, part taking) can be fully automatically controlled, reducing manual intervention, lowering the labor intensity of operators, and avoiding errors caused by manual operations, thereby improving the product qualification rate.

3. High Forming Precision and Good Surface Quality: The molten metal fills the cavity at high pressure and high speed, which can accurately replicate the details of the mold cavity. The formed parts have high dimensional precision (tolerance grade up to IT11-IT13) and low surface roughness (Ra≤1.6μm), which can be directly used for assembly without a lot of subsequent grinding, polishing and other post-processing procedures.

4. Less Molten Metal Loss and High Utilization Rate: The molten metal is always kept warm in the furnace without transfer, reducing heat loss and oxidation of the molten metal. At the same time, the utilization rate of molten metal during injection can reach more than 95%, reducing raw material waste and saving production costs.

5. Stable Process and Convenient Operation: Key process parameters (temperature, pressure, speed) can be accurately adjusted, the production process is stable, and the part quality is consistent; the equipment operation is relatively simple, and operators can take up their posts after simple training with low maintenance costs.

(II) Limitations

1. Limited Applicable Materials: Since the injection mechanism is directly immersed in the molten metal, limited by the melting point and corrosion of the material, it is only suitable for low-melting-point and low-corrosion metal materials, mainly zinc alloy, magnesium alloy, lead alloy, tin alloy, etc. (melting point usually below 450℃); it cannot be used for metals with high melting points, such as aluminum alloy, copper alloy, steel, etc. (high temperature will damage the injection mechanism).

2. Limited Part Size and Weight: Limited by the capacity of the injection mechanism and the clamping force, hot chamber die casting is mainly used for producing small, thin-walled components. The part weight is usually no more than 5kg, and the maximum size is generally no more than 500mm; for large and heavy metal parts, cold chamber die casting or other forming processes need to be adopted.

3. High Initial Equipment Investment: The structure of the hot chamber die casting machine is relatively complex, especially the high-pressure and high-precision models. The initial equipment purchase cost is high, and the installation and commissioning of the equipment are difficult, which increases the access threshold for small and medium-sized enterprises.

4. Fast Mold Wear: The molten metal fills the cavity at high pressure and high speed, which has a large scouring force on the mold. At the same time, the mold is in a high-temperature environment for a long time, which is prone to wear, deformation, cracking and other problems. The service life of the mold is relatively short, and it needs regular maintenance or replacement, which increases the production cost.

IV. Control of Key Process Parameters for Hot Chamber Die Casting

The part quality (dimensional precision, surface quality, internal compactness) of hot chamber die casting mainly depends on the control of key process parameters, especially the three core parameters of temperature, pressure, and speed, which need to be accurately adjusted according to material characteristics and part structure to avoid defects.

(I) Temperature Control

Temperature is the core parameter affecting the fluidity of molten metal and the solidification quality of parts. Two key temperatures need to be strictly controlled:

• Molten Metal Temperature: Set according to different materials. For zinc alloy, it is usually 380-420℃, and for magnesium alloy, it is 420-480℃. Excessively high temperature will lead to serious oxidation of the molten metal and defects such as shrinkage holes and air holes in parts; excessively low temperature will result in poor fluidity of the molten metal, failure to completely fill the cavity, and defects such as material shortage and cold shut.

• Mold Temperature: Usually controlled at 150-250℃, which needs to be kept uniform and stable. Excessively high mold temperature will prolong the part cooling time, reduce production efficiency, and cause difficulty in part demolding and surface sticking; excessively low mold temperature will cause the molten metal to cool too fast, resulting in defects such as cold shut and cracks. The temperature can be adjusted through the mold cooling channel or heating device.

(II) Injection Pressure Control

Injection pressure determines the compactness of molten metal filling and the strength of parts, which needs to be adjusted according to part thickness and structure, usually 10-50MPa:

• Low-Pressure Stage: The injection plunger moves downward slowly to discharge the air in the injection chamber. The pressure should not be too high (usually 2-5MPa) to avoid molten metal splashing;

• High-Pressure Stage: After the molten metal enters the mold cavity, the pressure is quickly increased to ensure that the molten metal is filled compactly, reducing defects such as air holes and shrinkage holes. Excessively high pressure will cause mold overflow and part flash, increasing post-processing difficulty; excessively low pressure will result in loose internal structure of parts and insufficient strength.

(III) Injection Speed Control

Injection speed is divided into slow injection speed and fast injection speed, which need to be reasonably matched to ensure stable filling and rapid forming of molten metal:

• Slow Injection Speed: Used in the initial stage of the downward movement of the injection plunger after liquid suction, the speed is usually 0.1-0.5m/s, aiming to push the molten metal stably to avoid eddy current and air entrainment;

• Fast Injection Speed: When the molten metal is about to enter the mold cavity, the speed is quickly increased (usually 1-5m/s) to ensure that the molten metal fills the entire cavity in a short time and reduces cold shut defects. However, excessively fast speed will cause serious scouring of the mold by the molten metal and air entrainment, resulting in air holes.

(IV) Other Key Parameters

In addition to the above three parameters, cooling time and ejection time also need to be accurately controlled: the cooling time is set according to the part thickness, usually 3-30 seconds, to ensure that the part is completely solidified and easy to demold; the ejection time needs to match the cooling time to avoid part deformation and cracks caused by premature ejection.

V. Industrial Application Scenarios of Hot Chamber Die Casting

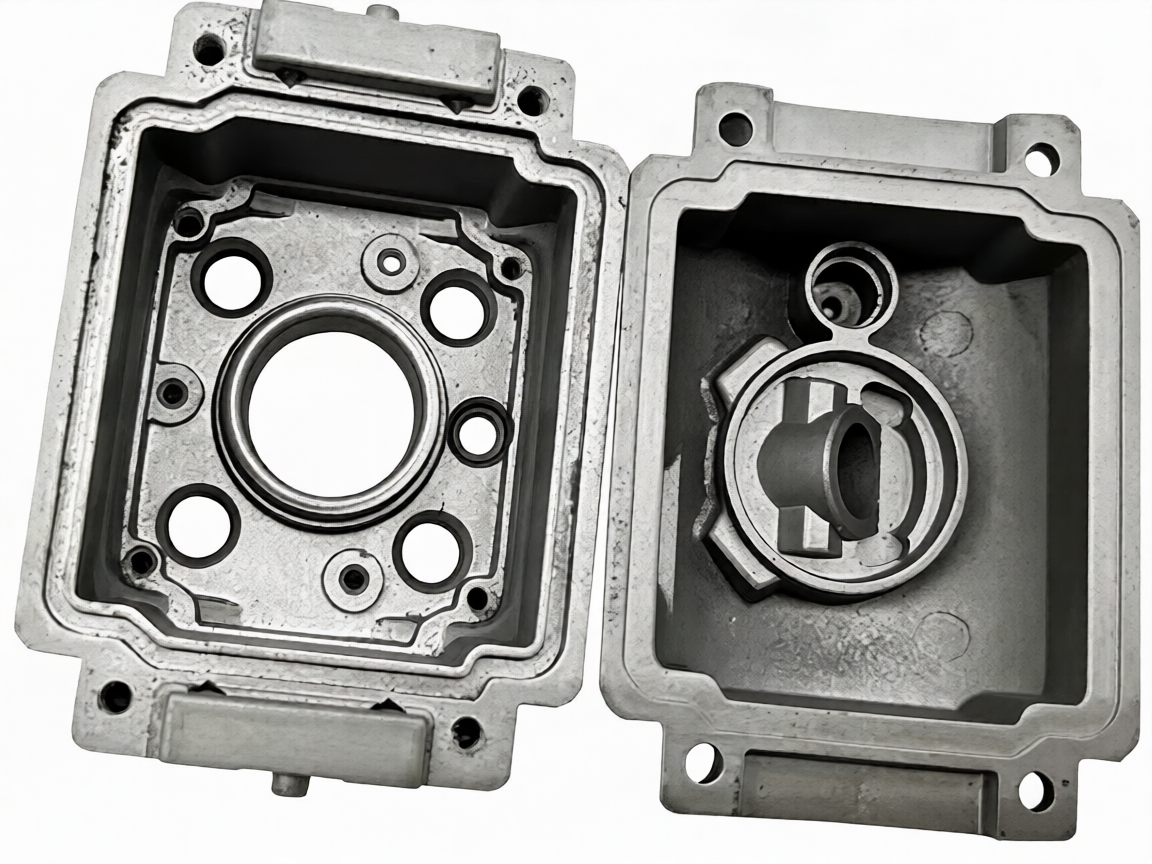

Based on the core advantages of "high efficiency, precision, and mass production" of hot chamber die casting, combined with its material and size limitations, it is mainly used for producing small, precision, thin-walled low-melting-point metal components, covering many industries. The following are analyses of typical application scenarios:

(I) Automotive Industry (Core Application Field)

The automotive industry is the most widely used field of hot chamber die casting, mainly used for producing small internal, external, and functional components of automobiles, especially zinc alloy and magnesium alloy parts, which take into account light weight and precision:

• Interior Components: Automobile door handles, instrument panel brackets, air conditioning outlet paddles, window lifter switch housings, seat adjustment knobs, etc., which require smooth surface and precise size and can be directly assembled;

• Exterior Components: Automobile logos, grille decorations, rearview mirror brackets, door latches, etc., which need to have a certain degree of corrosion resistance and aesthetics;

• Functional Components: Small gears of automobile gearboxes, steering system connectors, small brake system accessories, etc., which require high strength and high dimensional precision to ensure stable operation.

(II) Consumer Electronics Field

The consumer electronics field has extremely high requirements for miniaturization, precision, and light weight of components. Hot chamber die casting is exactly suitable for this demand, mainly used for producing zinc alloy and magnesium alloy housings and structural parts:

• Mobile Phone Components: Mobile phone middle frames, camera brackets, key housings, etc., which require precise size and flat surface to adapt to the precision assembly of mobile phones;

• Computers and Peripherals: Laptop housings, mouse housings, keyboard brackets, etc., which adopt magnesium alloy die casting to achieve the combination of light weight and high strength;

• Other Electronic Accessories: Earphone housings, smart watch cases, charger housings, etc., which take into account aesthetics and practicality and can be mass-produced to reduce costs.

(III) Medical Device Field

The medical device field has strict requirements on the precision, cleanliness, and safety of components. Hot chamber die casting can produce small metal components that meet medical standards, mainly using lead-free zinc alloy or magnesium alloy:

• Diagnostic Equipment Accessories: Handheld diagnostic instrument housings, detection probe brackets, internal instrument connectors, etc., which require precise size and no impurities to ensure stable operation of the equipment;

• Surgical Instrument Accessories: Small surgical instrument handles, forceps housings, syringe push rods, etc., which require smooth surface and no burrs, meeting medical cleanliness standards;

• Rehabilitation Equipment Accessories: Small wheelchair connectors, prosthetic structural parts, etc., which require high strength and good durability to adapt to long-term use needs.

(IV) Other Fields

In addition to the above three fields, hot chamber die casting is also widely used in hardware accessories, toy manufacturing, aerospace (small precision accessories), home appliance fields, etc.:

• Hardware Accessories: Door lock housings, key blanks, hinges, faucet handles, etc., which have high mass production efficiency and good surface quality, without a lot of post-processing;

• Toy Manufacturing: Metal toy components, model parts, such as toy car housings and robot structural parts, which can accurately replicate mold details and have rich shapes;

• Home Appliance Field: Small metal connectors and knobs of washing machines, air conditioners, and refrigerators, which require precise size and good durability to adapt to the long-term operation of home appliances.

VI. Development Trends of Hot Chamber Die Casting

With the transformation of manufacturing towards refinement, automation, and greenization, the hot chamber die casting process is constantly upgrading and optimizing, breaking through existing limitations and expanding application boundaries. In the future, it will mainly present four development trends:

(I) Automation and Intelligence Upgrade

In the future, hot chamber die casting will gradually realize full-process intelligent control, introducing industrial robots, machine vision, AI algorithms and other technologies to realize full automation of part taking, burr cleaning, quality inspection, and mold maintenance, reducing manual intervention, improving production efficiency and product consistency; at the same time, through the intelligent monitoring system, real-time monitoring of process parameters, automatic adjustment of parameter deviations, and reduction of defect rate.

(II) Expansion of Material Application

To address the existing material limitations, develop new high-temperature and corrosion-resistant injection mechanism materials, and gradually expand the applicable material range of hot chamber die casting, such as low-melting-point aluminum alloy and new magnesium alloy, breaking the limitation of "only applicable to low-melting-point metals" and expanding application scenarios; at the same time, develop environmentally friendly lead-free and cadmium-free metal materials to conform to the global development trend of green manufacturing.

(III) Breakthrough in Precision and Enlargement

By optimizing mold design, improving injection mechanism precision, and improving process parameters, promote the development of hot chamber die casting towards higher precision. The part size tolerance grade can be improved to IT10 and above, and the surface roughness can be further reduced to meet the needs of high-end fields; at the same time, develop large-scale hot chamber die casting machines, break through the limitations of part size and weight, and produce larger and more complex components to expand application boundaries.

(IV) Green and Energy-Saving Development

Optimize the furnace heating method, adopt energy-saving heating elements to reduce electric energy consumption; develop molten metal recycling technology to improve raw material utilization and reduce waste; improve the mold cooling system, adopt circulating cooling technology to save water resources; at the same time, reduce waste gas and residue emissions during production to realize green production, conforming to global environmental protection policies and the green transformation needs of the manufacturing industry.

VII. Conclusion

As an efficient and precision metal forming process, Hot Chamber Die Casting has become the core process for mass production of low-melting-point metal components, relying on its core advantages of high efficiency, high automation, and excellent forming precision, and plays an irreplaceable role in various fields such as automotive, consumer electronics, and medical devices. Although it has limitations in applicable materials and part size, these limitations are gradually being broken with the continuous upgrading of technology.

In the future, with the integration of automation, intelligence, and greenization technologies, the hot chamber die casting process will achieve higher quality, higher efficiency, and wider application. It will not only promote the upgrading and development of the metal forming manufacturing industry but also provide more precise and economical forming solutions for the high-end manufacturing industry, helping the manufacturing industry move towards refinement, high added value, and greenization. For enterprises, mastering the core technology and parameter control technology of hot chamber die casting will become the key to seizing market opportunities and improving product competitiveness.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.