Consumer Electronics Low-Volume One-Stop Manufacturing

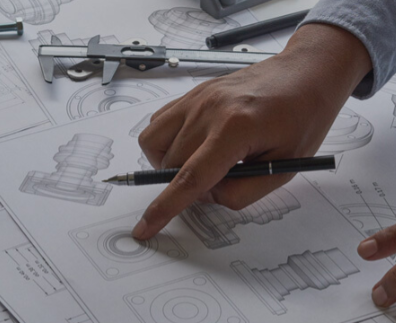

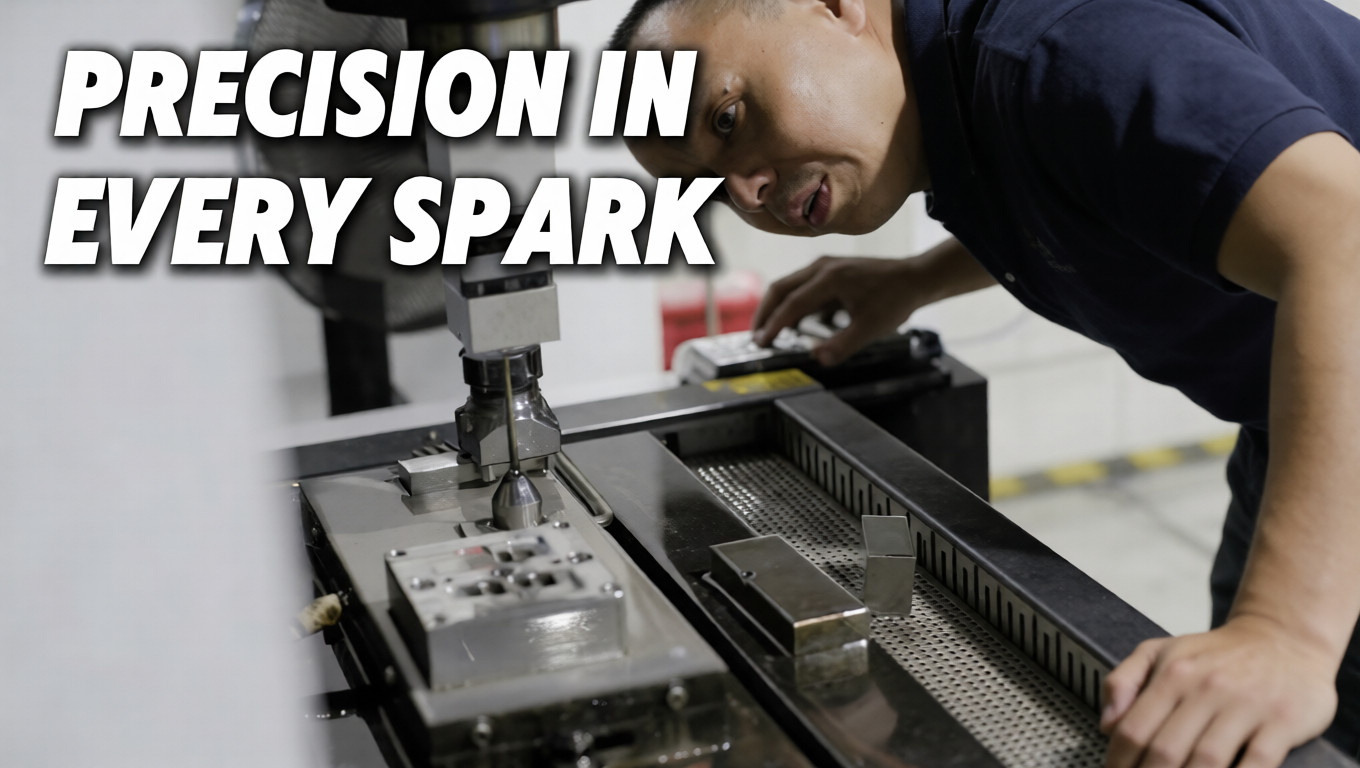

Mastars provides one‑stop small‑to‑medium‑volume manufacturing for the Consumer Electronics industry, covering DFM review, rapid prototyping, tooling, injection molding, die casting, CNC machining, sheet metal fabrication, PCBA, and final assembly. Our integrated workflow and IQC/IPQC/OQC quality control ensure your products move from concept to market with speed, quality, and cost efficiency. We support low‑volume production with no minimum order quantities (MOQ) and fast iteration to match the fast‑paced CE lifecycle. Typical parts include enclosures, brackets, heat sinks, metal hardware, and PCBA subassemblies.

From NPI to ramping, we offer flexible capacity and engineering support—including test jigs/fixtures, process optimization, and supply‑chain coordination—to shorten development cycles and reduce NRE and inventory risk. A full range of finishing options (e.g., painting, plating, anodizing, silk screening) enhances aesthetics and functionality, while our digital, end‑to‑end manufacturing solutions enable faster, more affordable delivery for smartphones, wearables, smart home/IoT devices, audio, displays, and computer peripherals.

Consumer Electronics Parts Mastars Serves

Material Options For Consumer Electronics

✔️ Thermoplastics

·PEEK ·ABS ·PC ·PVC

✔️ Elastomers

·NR ·IR ·SBR ·BR ·NBR/Buna-N

✔️ Metals

·Stainless Steel ·Copper·Brass ·Aluminum

Prototype and Production Parts For Electronics Industry

✔️ Board components

✔️ Circuits and Printed Circuit Boards (PCBs)

✔️ Knobs and dials

✔️ Heat sinks

✔️ Fans and extractors

✔️ Enclosures and casings

✔️ Handles

✔️ Buttons and switches

✔️ Phone cases

✔️ Mobile accessories cover

✔️ Fixtures

✔️ Wearable devices

✔️ Sensor devices

✔️ Electronic security

✔️ Satellite comms

✔️ Semiconductors

✔️ Battery components

Why Choose Mastars

✔️Custom, On-demand Solutions -- On‑demand offerings include sprayers, tillage, nozzles, irrigation devices, automated solar components, and material‑handling equipment tailored to your farm, factory, or supply chain

✔️Low‑volume Production -- Aligning with diverse budgets, helping you control costs and reach market faster.

✔️Rapid Prototyping -- Parts in as fast as 24 hours

✔️Quality Guaranteed -- Every part is made to specifications with dimensional accuracy, premium finishes, and optimized functionality.

✔️One‑stop‑shop Service -- In‑house fabrication with strict quality management and process control for part consistency and on‑spec delivery.

✔️Material Inspection and Compliance -- All parts meet end‑use requirements for smooth approval and regulatory inspections.

Post-Processing Capabilities

✔️ Anodizing

✔️ Passivization

✔️ Electroplating

✔️ Powder Coating

✔️ Insert Installation

✔️ Heat Treatment

✔️ Texturing

✔️ Blasting

✔️ Painting

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.