Aluminum Die Casting

with Mastars

Durable, precise, cost-effective—aluminum die casting for high-volume production of automotive, medical, and consumer parts.

Aluminum Die Casting Service

Aluminum die casting forces molten aluminum/alloy into steel molds for part production. It enables intricate, precise (straight/flat) components with a fine surface finish, favored for high strength-to-weight ratio, corrosion resistance, and heat dissipation.

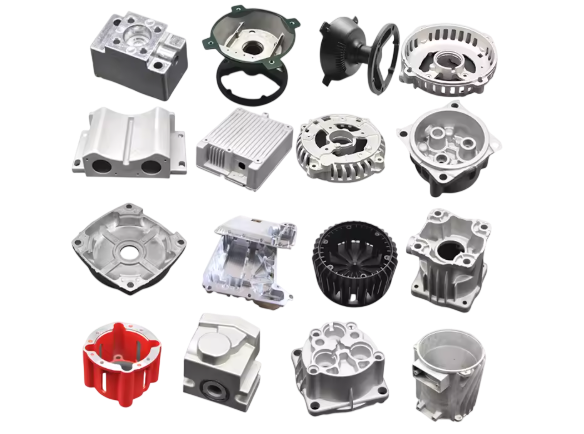

Die Casting Parts We Manufactured

Mastars Die Casting Capabilities

| Details | ||||

| Tolerance | High-precision die casted parts need secondary machining to meet tolerance requirements, achieving accuracy up to ±0.01mm | |||

| Minimum Wall Thickness | Aluminum alloy recommended 1.5mm, zinc alloy can go down to 0.8mm | |||

| Wall Thickness Ratio | Keep within 1:3 ratio to avoid uneven filling | |||

| Hole Diameter | Due to high temperatures during aluminum die casting mold processing, round holes smaller than 3mm diameter require secondary drilling. Product threaded holes and external threads are formed through secondary machining. | |||

| Draft Angle | Minimum 0.5° to avoid demolding difficulties | |||

| Maximum Die Life (Number of Cycles) | Zinc: 1,000,000 Magnesium, Aluminum: 100,000 | |||

| MOQs | 1 pieces | |||

| Lead Time | 3-10 days. Specific timing varies based on mold type and product structure complexity | |||

Why Choose Mastars for Die Casting

High-precision metal parts with integrated post-processing and full-BOM support.

T1 Samples As Fast As 3 Days

Mastars' Factory and Advanced Equipments

Our Ideas Have Helped Clients Bring Hundreds Of Products To Market

Aluminum Die Cast Products Gallery

Products

Aluminum Die Casting Material Options

Materials Gallery

View the hundreds of materials available at Protolabs through all of our service lines.

Quality Assurance

At Mastars, quality underpins every process—from tooling to standards. Our ISO 9001, ISO 14001 and IATF 16949 certifications ensure consistent excellence.

Advanced Inspection Equipment

Comprehensive Testing Procedures

Proven Quality Standards

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.