Sports Industry Prototyping and Manufacturing Services

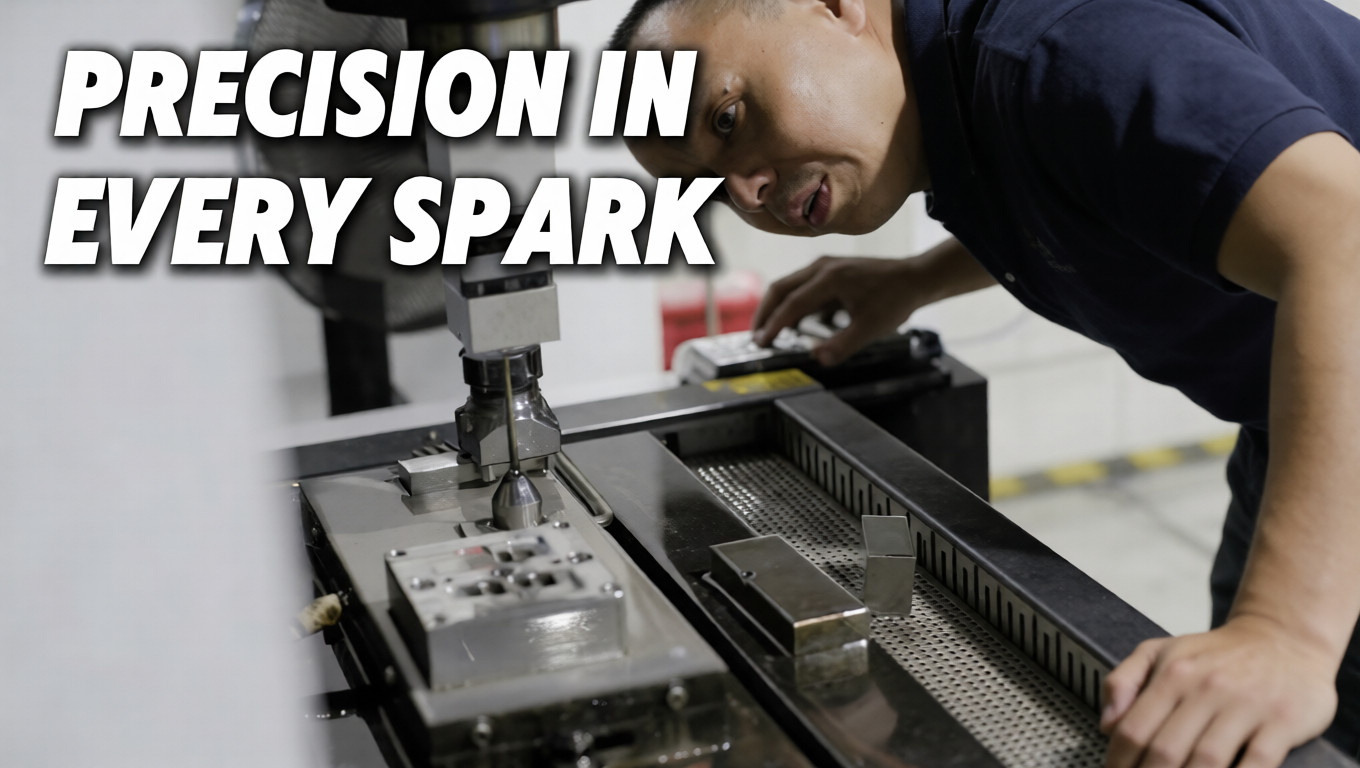

Mastars provides end‑to‑end OEM/ODM contract manufacturing for the sports industry, covering prototyping—tooling—jigs/fixtures—scalable production—assembly—secondary machining and surface finishing for plastic and metal sports components. With multi‑factory coordination and a rapid‑response engineering team, we support the full journey from low‑volume pilot runs to mass production, meeting the industry’s demands for lightweight construction, high strength, weather resistance, and visual consistency across applications such as outdoor sports, sports equipment, and protective gear.

Our manufacturing capabilities span injection molding and mold making, die casting and tooling, sheet metal stamping and laser cutting, CNC precision machining, metal injection molding (MIM), plastic and metal extrusion, assembly, and secondary operations, supported by a full range of surface treatment and finishing options. For prototyping, we offer CNC rapid prototyping as well as SLS/SLA/SLW additive manufacturing and vacuum casting to accelerate design validation and iteration—shortening time‑to‑market while ensuring stable, repeatable mass‑production quality.

Sports Parts Mastars Serves

Materials for Sports Applications

Metals: ✔️Structural steel ✔️stainless steel ✔️high‑strength steel ✔️aluminum alloys ✔️and titanium

Composites: ✔️CFRP (carbon fiber reinforced polymer) ✔️GFRP (glass fiber reinforced polymer) ✔️KFRP (aramid)

Engineering thermoplastics: ✔️PA6/PA66 ✔️POM ✔️PC ✔️ABS ✔️PBT

Elastomers and foams: ✔️TPU ✔️TPE ✔️EVA ✔️EPDM ✔️NBR ✔️Latex

Performance textiles and surfaces: ✔️Polyester ✔️Nylon (textiles), ✔️Silicone

Typical Sports & Outdoor Applications

✔️ Performance footwear and boot systems

✔️ Sports equipment and hardware components

✔️ Outdoor gear structural parts

✔️ Lightweight frames, housings, and interfaces

✔️Integrated assemblies for performance-driven products

Why Choose Mastars

✔️Integrated manufacturing across multiple processes

✔️Engineering-led approach to performance requirements

✔️ Strong DFM and tooling discipline

✔️ Experience supporting proprietary materials and complex components

✔️ Reliable production execution and scalable delivery

✔️ Dual-base manufacturing support (USA + China)

Sports Products Post-Processing Capabilities

✔️ Anodizing

✔️ Passivization

✔️ Electroplating

✔️ Powder Coating

✔️ Insert Installation

✔️ Heat Treatment

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.