Robotics Manufacturing Services

Mastars delivers end‑to‑end robotics and automation from concept—DFM—rapid prototyping—tooling—pilot—mass production, covering plastics, metals, electronics, and testing. We align mechanical, motion, and coating disciplines and implement cost control from day one, turning bold ideas into shippable, scalable products via our end‑to‑end supply chain.

Our stack uses GD&T/CMM + preload for tolerance control; optimizes lead-screw/motor matching via lead compensation and end-point calibration to reduce backlash; suppresses resonance and ensures microstepping linearity for stable trajectories; and applies wear management, thermal drift compensation and SPC for durability. With mature, cost-effective solutions (e.g., roll-forming lead screws), standardized suppliers and full-process control (machining-injection-assembly-EOL), we achieve ~10% cost reduction, 10,000 units/year output, cross-batch consistency, faster time-to-market and maximized yield from NPI to volume production.

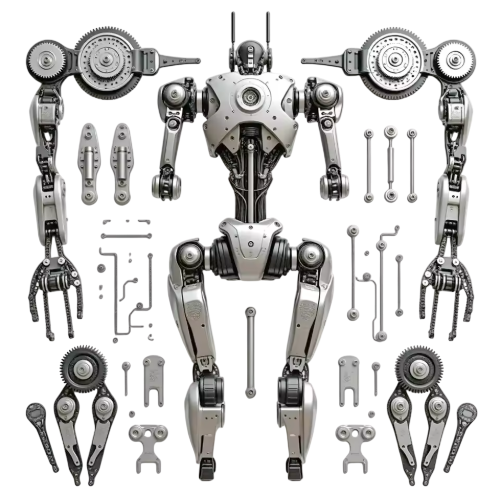

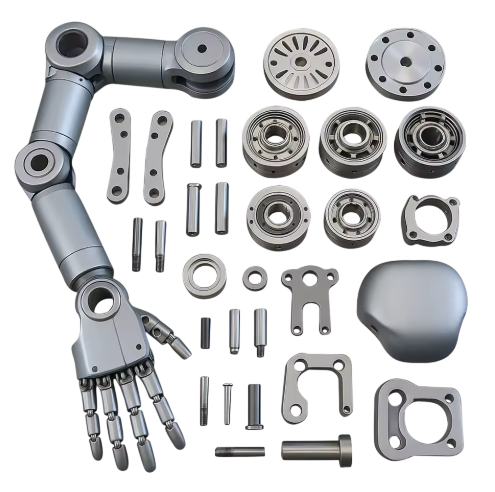

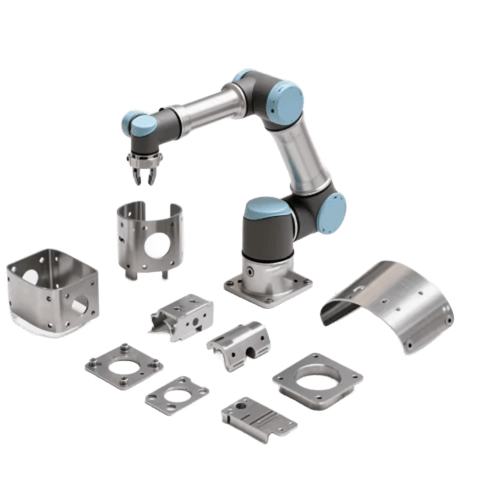

Robotic Parts Mastars Serves

Quality Measures for Robotics Industry

| CMM inspection report | First Article Inspection (FAI) | |||

| Dimensional Inspection Report (DIR) | PPAP | |||

| Material Certificates + Certificate of Analysis | Conflict Minerals Reporting | |||

| REACH + RoHS Certificates | Prop65 | |||

| Industry Certifications: ISO 9001 and IATF16949 | Certificate of Conformance (CoC) | |||

Materials for Robotics Applications

✔️ Aluminum

A top pick for robotics thanks to its lightweighting; select alloys also offer corrosion resistance, good weldability, and high heat resistance—key for demanding applications.

✔️ Stainless Steel

Widely used in robotics, stainless steel combines strength and corrosion resistance to keep robotic components reliable through repeatable cycles and tough operating conditions.

✔️ Acetal/Delrin

For robots needing tight tolerances and smooth, repeatable motion, Acetal delivers superior dimensional stability and low friction at a lower cost than many industry standards.

✔️ Elastomers

Driven by soft robotics, elastomers are increasingly popular in robotics for their ability to handle fragile operations safely and smoothly; inside standard robots, they provide the flex needed in parts such as semiconductors and casings.

Top Precision Robotics Applications

✔️ Low volume prototype, pilot, or short-term production support using: Injection molding, urethane casting, small part stampings

✔️ LProduction parts supply: Bridge tooling & parts supply, low to medium volume tooling parts supply, service parts supply using new or existing tooling

✔️ Rapid prototyping with: Additive manufacturing, CNC machining

✔️ Plant floor manufacturing support: Custom assembly fixtures/equipment/jig details, custom check fixture or part check details

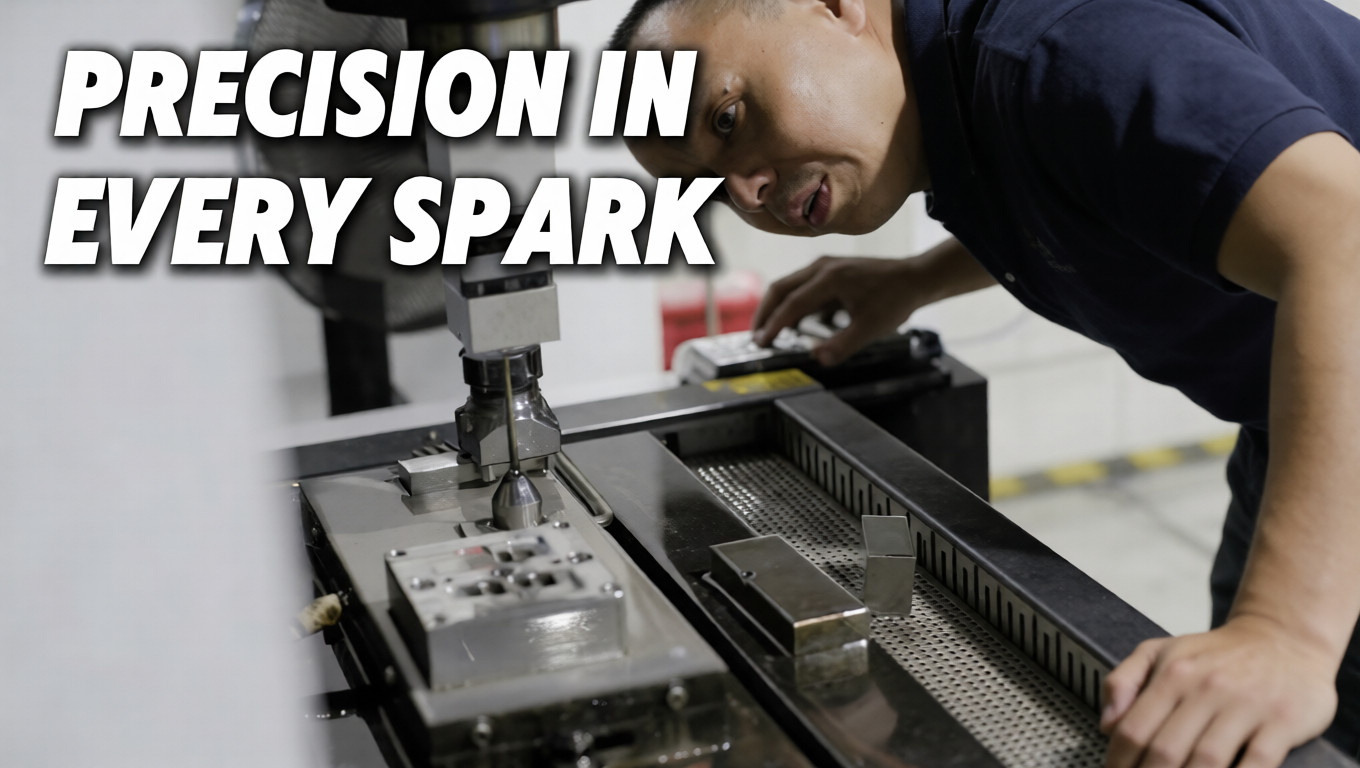

Precision Manufacturing for Robotics Industry

Robotics is a diverse and rapidly evolving field that has seen especially strong adoption in the industrial and manufacturing sectors. Typical applications include robotic arms, collaborative robots (cobots), robotic process automation (RPA), integrated AI, predictive maintenance, and service robots, reflecting its breadth across operations and industries.

For robotic components, dimensional accuracy is critical: parts are often complex and must maintain precise fits to operate reliably with other assemblies while withstanding the stresses of repetitive motion. Key considerations also include customizability, low‑friction surface finishes, and the ability to produce complex geometries—making digital manufacturing uniquely valuable for the production and assembly of high‑performance robotic parts.

Robotics Post-Processing Capabilities

✔️ Anodizing

✔️ Passivization

✔️ Electroplating

✔️ Powder Coating

✔️ Insert Installation

✔️ Heat Treatment

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.