Plastic Injection Molding

with Mastars

Request an online quote today for custom plastic parts delivered in days.

Plastic Injection Molding

Injection molding is a high-efficiency process: molten plastic is injected into a precision mold, cooling into the final part. With minimal waste and low per-unit costs, it’s widely used for large-scale plastic production in medical, consumer goods, and automotive sectors.

Our custom injection molding offers 1-day lead times—ideal for prototypes and end-use parts. Using cost-effective aluminum molds and 200+ thermoplastics, we deliver rapid turnaround and consistent quality for diverse projects.

Plastic Molding Capabilities

Our basic guidelines for plastic injection molding include important design considerations to help improve part moldability, enhance cosmetic appearance, and reduce overall production time.

| Type | US | Metric | ||

| Size | 18.9 in. x 29.6 in. x 8 in. | 480mm x 751mm x 203mm | ||

| Volume | 59 cu. in. | 966,837 cu. mm | ||

| ABS | 4 in. from parting line | 101mm from parting line | ||

| Up to 8 in. if parting line can pass through the middle of the part | Up to 203.2mm if the parting line can pass through the middle of the part | |||

| Projected Mold Area | 175 sq. in. | 112,903 sq. mm | ||

| ABS-Like | ABS-Like Translucent/Clear (WaterShedXC 11122) | Injection Molding | ||

Thermoplastic Materials

✔️ General Purpose Plastics

●HDPE ●LDPE ●LLDPE ●PS ●Polypropylene

✔️ Engineering Plastics

●ABS ●ABS/PC ●Acetal ●Acetal Homopolymer/Delrin ●ETPU ●Nylon ●PBT ●PC/PBT ●Polycarbonate ●PET ●PETG ●PMMA (Acrylic, Plexiglas) ●PPE/PS ●PPA ●TPU

✔️ High-Performance Engineering Plastics

●LCP ●PEEK ●PEI ●PSU

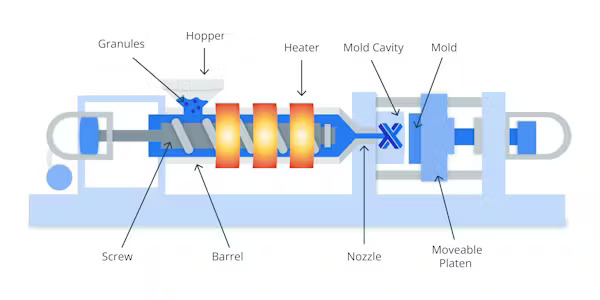

How Custom Plastic Injection Molding Works

Plastic injection molding requires an injection machine, raw plastic, and a mold. Melted plastic is injected into the steel/aluminum mold, then cools and solidifies into the final part.

Xometry reviews your injection molding quote & parts for manufacturability, aligns specs, lead time and price with your needs, CNC machines molds via 3D CAD, sends T1 samples for approval, refines molds and starts production—covering medical, automotive, aerospace and defense parts.

Our Ideas Have Helped Clients Bring Hundreds Of Products To Market

Injection Mold Finishes & Post-Processing Options

| Type | Material | |||

| Standard Finish | Moldmaker-selected finish, typically SPI B-2 (varies by geometry and drafts). Interior non-cosmetic surfaces are as-machined. | |||

| SPI Finishes | Full range of SPI finishes available, spanning Grade 3 diamond high polish to 320 stone low polish—including SPI A-1 to D-3 grades. | |||

| MoldTech Finishes (Mold Texturing) | A range of finishes (matte, swirl, line, pattern) is available; our most common textures include MoldTech MT11010, MT11020, MT11030, with custom textures on request. | |||

| Other Textures - VDI | VDI 3400 Surface Finish is a mold texture standard issued by Germany’s Verein Deutscher Ingenieure (VDI), primarily processed via EDM to produce matte finishes ranging from fine to coarse. | |||

| As Molded | No secondary polishing or grinding. Part will show tooling marks. | |||

| Threaded Inserts | We can install most commonly used standard inserts in UNF and metric sizes. | |||

| Pad Printing | Transfer a 2D image onto a 3D part. All images are subject to review. | |||

| Laser Engraving | Engrave part numbers, logos, and more onto your parts. | |||

| Assembly | Mastars provides assembly and labeling services for injection molded parts—consult your Mastars representative to discuss your specific needs. | |||

Surface Finish Options

We don't have MOQ, only 1pcs is according to high standard to make, we pursuit the product is perfect to every customer, from 1pcs to million,we are glad to witness and grow together with our customers, that make us proud.

Draft angle requirements will vary by requested finish. Industry standard Mold-Tech finishes are also available.

| Finish | Description |

| PM-F0 | non-cosmetic, finish to Protolabs' discretion |

| PM-F1 | low-cosmetic, most toolmarks removed |

| PM-F2 | non-cosmetic, EDM permissible |

| SPI-C1 | 600 grit stone, 10-12 Ra |

| PM-T1 | SPI-C1 + light bead blast |

| PM-T2 | SPI-C1 + medium bead blast |

| SPI-B1 | 600 grit paper, 2-3 Ra |

| SPI-A2 | grade #2 diamond buff, 1-2 Ra |

Applications and Advantages of a Plastic Injection Molding Service

Rapid Prototyping

Production Parts

Range of Industries and Certifications

Our molding services meet strict qualification and quality standards, holding ISO 9001, ISO 13485, IATF 16949, plus ISO 7 & 8 Medical Clean Room molding capabilities.

Custom Injection Moldings Design Guidelines

| Feature | Tip | ||

| Undercuts | Add pass-thru coring to reduce undercuts, which would otherwise increase the complexity and cost of mold ejection mechanisms | ||

| Wall Thickness | Maintain uniform wall thickness to prevent sink marks and voids; thinner walls reduce cycle time and cut costs | ||

| Drafts | Design parts with a minimum 0.5° draft angle—up to 5° for medium-textured surfaces | ||

| Ribs/Gussets | Design ribs to be 40–60% of the outer wall thickness, with draft angles maintained at all times. | ||

| Bosses | Bosses are designed to 30% of the wall thickness in depth with a 30% edge groove; attach them to side walls or ribs for structural integrity | ||

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.