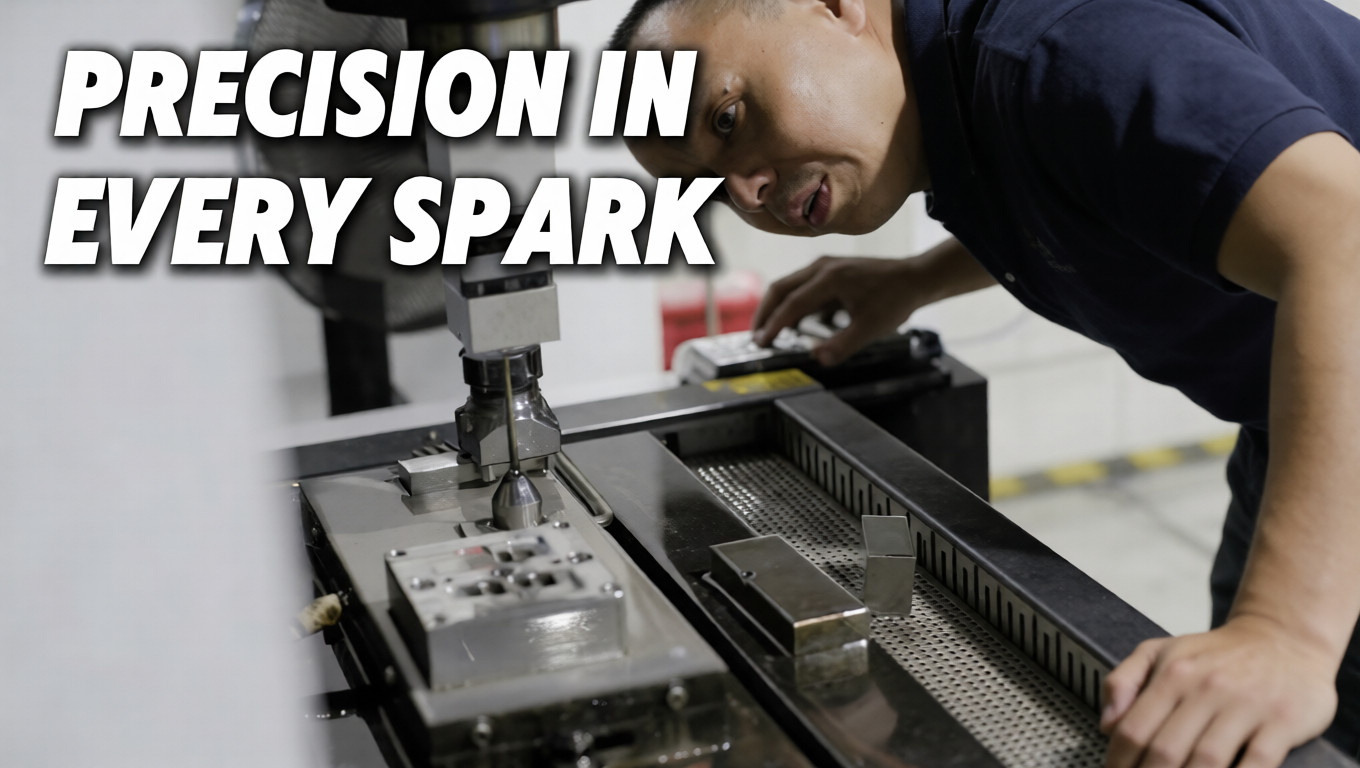

Defense Products Manufacturing

Mastars provides end‑to‑end manufacturing for the defense and military sector, from DFM and rapid prototyping through tooling, pilot runs, and high‑volume production, covering plastics, metals, electronics, and testing. Supported by an integrated supply chain and rigorous quality and cost‑control systems, we help customers turn concepts into shippable products and sustain consistent, cross‑batch performance from validation to scaled delivery.

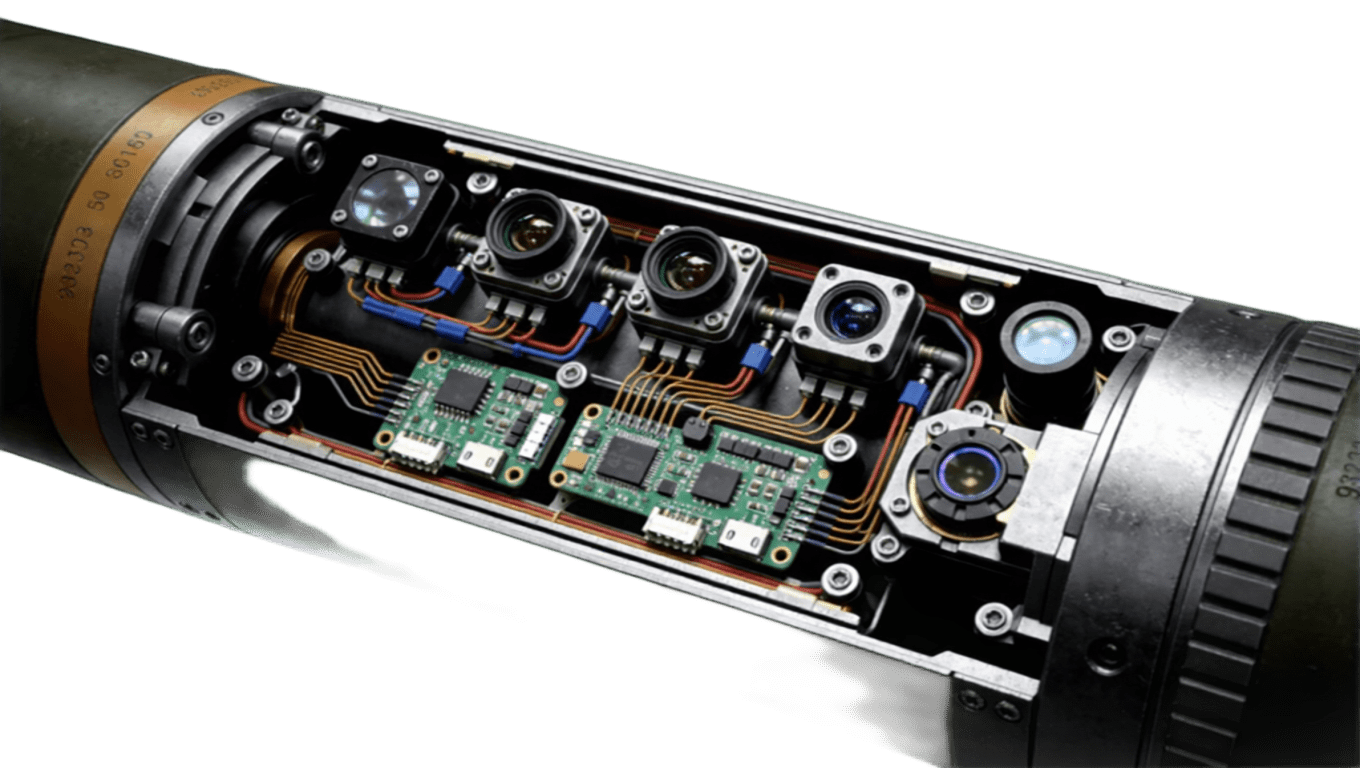

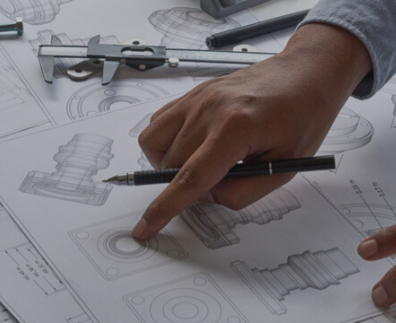

Our stack uses GD&T/CMM + preload for tolerance control; optimizes lead-screw/motor matching via lead compensation and end-point calibration to reduce backlash; suppresses resonance and ensures microstepping linearity for stable trajectories; and applies wear management, thermal drift compensation and SPC for durability. With mature, cost-effective solutions (e.g., roll-forming lead screws), standardized suppliers and full-process control (machining-injection-assembly-EOL), we achieve ~10% cost reduction, 10,000 units/year output, cross-batch consistency, faster time-to-market and maximized yield from NPI to volume production.

Defense Parts Mastars Services

Materials for Defense Applications

✔️ Titanium

Lightweight yet strong, this material is available via machining and metal 3D printing services, offering excellent corrosion and temperature resistance.

✔️ Stainless Steel

Widely used in robotics, stainless steel combines strength and corrosion resistance to keep robotic components reliable through repeatable cycles and tough operating conditions.

✔️ Aluminum

High strength‑to‑weight makes this metal ideal for load‑bearing housings and brackets; available as CNC‑machined and 3D‑printed parts.

✔️ Inconel

Nickel‑chromium superalloy parts made by 3D printing offer outstanding high‑temperature resistance, making them ideal for rocket engine components and other extreme‑heat applications.

✔️ Liquid Silicone Rubber

Fuel‑ and oil‑resistant elastic fluorosilicone is tailored for demanding sealing; our optical silicone rubber offers a high‑clarity alternative to PC/PMMA.

Top Precision Defense Applications

✔️ Aircraft interiors

✔️ Spacecraft and satellite components

✔️Telecommunications components

✔️ Optical system components

✔️ Military rifle components

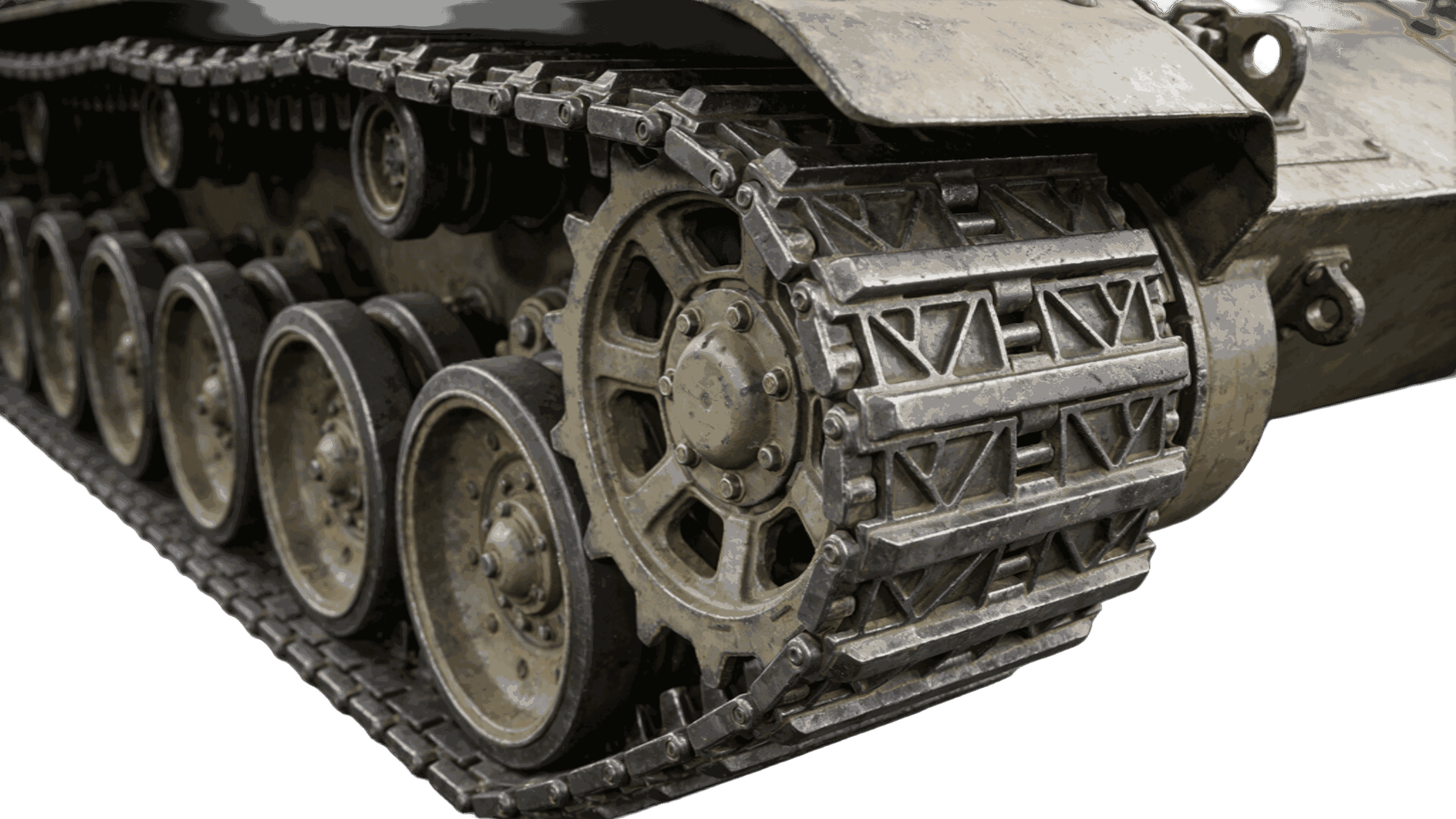

✔️ Military vehicle components

✔️ Military UAV and drone components

✔️ High-performance tools and fixtures

Why Choose Mastars?

✔️ We know the challenges your parts face—whether on the ground, in the air, or in space. Backed by certifications and deep technical expertise, we deliver high‑performance, cost‑effective components that hit your specs.

✔️ From early prototypes for design validation to late‑stage ones for fit, finish, and function—plus bridge and full production—we support you through the entire product lifecycle.

✔️ Our unmatched range of manufacturing tech—additive manufacturing, injection molding, sheet metal forming, precision CNC machining—covers every need.

✔️ We have a proven record delivering top‑quality parts to aerospace firms, military agencies, and other leaders in these cutting‑edge fields.

✔️ And we’re problem solvers. Got complex geometries, short‑run/high‑mix parts, or “impossible” projects? Bring them to us—we’ll get it done.

Defense Industry Post-Processing Capabilities

✔️ Anodizing

✔️ Passivization

✔️ Electroplating

✔️ Powder Coating

✔️ Insert Installation

✔️ Heat Treatment

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.