Multi-Cavity and Family Molding Servic

Maximize each mold shot by producing multiple identical or different parts in one cycle

What is Multi-Cavity and Family Molding?

Family molding is a highly efficient, widely used injection molding technique for producing multiple associated plastic parts in one cycle. Its core lies in family molds—specialized molds integrating cavities for different components into a single set. During molding, molten plastic is distributed via a pre-designed runner system to fill all part cavities simultaneously.

A typical case is automotive interior production: a family mold for door panels can mold handles and storage boxes at once, with all components formed under identical process parameters (temperature, pressure, injection speed) for consistent quality.

Applications for Multi-Cavity and Family Molding

✔️ Automotive: For high-volume fasteners, connectors, sub-assembly components, interior trim sets, and small standard parts

✔️ Construction: Commodity items like fittings, fasteners, connectors, and closures

✔️ Consumer Electronics: Standardized components used across many units, housings, and internal components for specific devices

✔️ Construction: Commodity items like fittings, fasteners, connectors, and closures

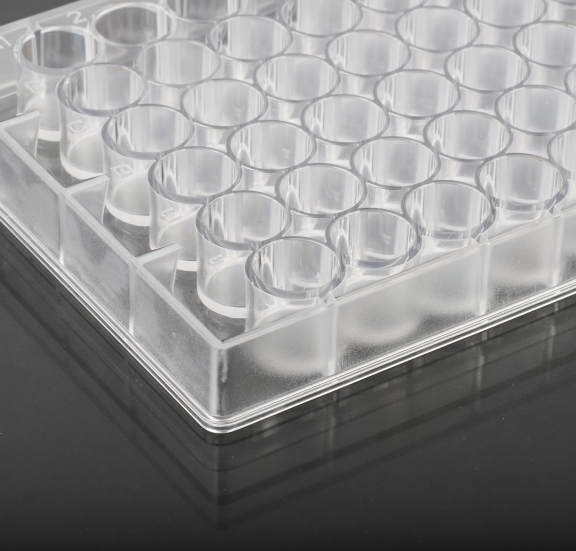

✔️ Packaging: Especially beverage, food, cosmetic, and pharmaceutical packaging

✔️ Appliances: Housings and components for smaller appliances

Mastars Multi-Cavity & Family Injection Molding Products

Materials Options

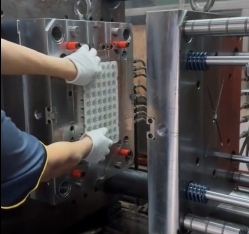

How does Multi-Cavity & Family Molding Work?

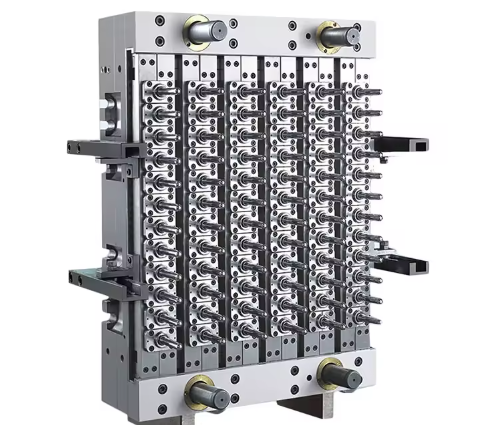

Multi-cavity and family injection molding are two efficient processes enabling multi-part production in one cycle, with distinct mechanisms for varied needs. Multi-cavity molding uses molds with multiple identical cavities; plastic melt is evenly delivered via a balanced runner system for simultaneous filling, ensuring mass production of consistent, same-spec parts. By contrast, family molding relies on specialized molds with cavities for different but related components, where melt is precisely fed through custom runners to mold all parts under identical conditions in one go.

Both processes boost efficiency by cutting mold changeover time and manufacturing costs. Widely used in automotive, electronics and consumer goods industries, they meet the core demand for cost-effective, high-quality plastic parts production.

Benefits of Multi-Cavity & Family Molding?

✔️ Cost Efficiency: Using a single mold for multiple assembly parts leads to lower overall tooling costs than making separate molds for each component.

✔️ Time Savings: Single-shot molding of all parts significantly reduces production time, and is particularly beneficial for assembly components that emerge synchronized and ready for downstream processes.

✔️ Material Consistency: Unified material injection delivers consistent properties, color and texture across parts, key to quality and aesthetics.

✔️ Ideal for Assemblies: It delivers consistent dimensions and appearance for kit/assembly parts, ensuring optimal assembly fit and aesthetic harmony.

✔️ Waste Reduction: Fewer molds + optimized runners cut scrap and boost resource efficiency; solidified runner material is recyclable (pelletized and mixed with virgin plastic, resin-dependent).

Key Design Considerations

Molding multiple parts in one cycle requires balancing function, manufacturability and performance, while reducing defects/inefficiencies. Critical factors to consider:

✔️ Part Similarity

✔️ Wall Thickness Uniformity

✔️Tolerance Stack-Up

✔️ Ejection and Venting

Family Molding and Multi-Cavity Molding Comparison

| Feature | Family Molding | Multi-Cavity Molding | ||

| Parts per cycle | Multiple different parts | Multiple identical parts | ||

| Best for | Assemblies, kits, low-to-medium volumes | High-volume production of a single part | ||

| Cost | Potentially higher upfront cost due to added complexity, but lower than multiple tools | Higher upfront cost than single-cavity, increased cost efficiency over time | ||

| Cycle time utilization | May be less efficient due to varied part geometries | Optimized for identical part geometry | ||

| Material consistency | Moderate – same material across parts, but geometry may affect flow and cooling | High across units (identical parts) | ||

| Complexity of mold design | Higher due to unbalanced flow, ejection needs | Moderate; symmetrical design simplifies flow | ||

| Risk of defects | Higher if parts differ significantly in size or shape | Lower as conditions are optimized per part | ||

| Flexibility for changes | Can accommodate multiple designs, but any change may affect all parts | A design change must be made across all cavities in production | ||

| Maintenance/Repair | May impact all parts of the tool | Only one part type affected | ||

Surface Finish Options

We don't have MOQ, only 1pcs is according to high standard to make, we pursuit the product is perfect to every customer, from 1pcs to million,we are glad to witness and grow together with our customers, that make us proud.

| Finish | Description |

| PM-F0 | non-cosmetic, finish to Protolabs' discretion |

| PM-F1 | low-cosmetic, most toolmarks removed |

| PM-F2 | non-cosmetic, EDM permissible |

| SPI-C1 | 600 grit stone |

| PM-T1 | SPI-C1 + light bead blast |

| PM-T2 | SPI-C1 + medium bead blast |

| SPI-B1 | 600 grit paper |

| SPI-A2 | grade #2 diamond buff |

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.