Insert Molding Service

with Mastars

Get custom plastic parts with metal inserts: upload your part for a quick online quote.

Insert Molding Service

Insert molding places a pre‑formed insert—commonly metal, but also ceramic or another plastic—into the mold cavity, then injects molten plastic to encapsulate it in a single step. This integrates multiple materials, enhances functionality, and reduces or eliminates secondary assembly. Typical inserts include threaded metal inserts for durable fastening and alignment. Cooling forms a solid, reliable part with the insert securely locked in place.

Metal inserts such as aluminum or stainless steel add tensile strength and conductivity, while plastic encapsulation improves wear resistance and structural integrity versus mechanical assembly. The process also supports size and weight reduction and is suitable for high‑volume production with consistent quality. RapidDirect offers insert molding services that achieve a strong, permanent bond between inserts and molded plastic for durable, high‑performance components.

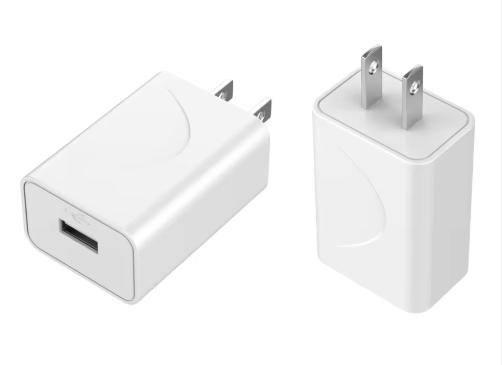

Products of Mastars Insert Molding Services

Custom Insert Molding With Mastars

Mastars offers insert mold services as part of its injection molding capabilities. For a free insert molding design review and quote, upload your CAD files. Our expert team of injection molders will get back to you within 24 hours.

Insert Molding is an injection molding process that works especially well for parts that have threaded holes. It can also help you create better wheels, pulleys, fan blades, and other similar parts. Done correctly, insert molding can help:

Materials for Insert Molding

| Type | Type | |||

| ABS | ABS Beige (Natural), ABS Black, ABS Black Antistatic, ABS Milky White, ABS+PC Black, Flame Retardant ABS Beige, Flame Retardant ABS Black | |||

| PC | PC Black, PC Transparent, PC White, PC Yellowish White, PC+GF30 Black | |||

| PMMA (Acrylic) | PMMA Black, PMMA Transparent, PMMA White | |||

| POM | Dark brown (coffee) POM 100AF, POM Black, POM Blue, POM White | |||

| PA (Nylon) | PA(Nylon) Blue, PA6 (Nylon)+GF15 Black, PA6 (Nylon)+GF30 Black, PA66 (Nylon) Beige(Natural), PA66 (Nylon) Black | |||

| PE | PE Black, PE White | |||

| PEEK | PEEK Beige(Natural), PEEK Black | |||

| PP | Food Grade PP White, PP Black, PP White, PP+GF30 Black | |||

| HDPE | HDPE Black, HDPE White | |||

| HIPS | HIPS Board White | |||

| LDPE | LDPE White | |||

Insert Molding Capabilities

| Standards | Metric | |||

| Maximum Part Size | 800×1000×400mm 31.50×39.37×15.75 in. | |||

| Manimum Part Size | 2×2×2mm 0.08×0.08×0.08in | |||

| Substrate Wall Thickness | From 0.5 to 3mm From 0.20 to 0.12 in. | |||

| Tolerance | +/- 0.025 mm +/- 0.00098 in. | |||

| Inserts | Inserts can be female and male. They both can improve a product’s appearance and utility. | |||

| Mold Validation | Provide T0, T1, T2 samples before mass production | |||

| Inspection and Certification Options | First Article Inspection, ISO 9001, ISO 13485 | |||

| Lead Time | From mold making to sample delivery: 15-45 business days | |||

Insert Molding Design Guidelines

We don't have MOQ, only 1pcs is according to high standard to make, we pursuit the product is perfect to every customer, from 1pcs to million,we are glad to witness and grow together with our customers, that make us proud.

Our overmolding & insert molding guidelines cover key design considerations to boost part manufacturability, elevate aesthetics, and shorten production timelines.

| US | Metric | |

| Maximum Part Size | 18.9 in. x 29.6 in. x 8 in. | 480mm x 751.8mm x 203.2mm |

| Volume | 59 cu. in. | 966,837 cu. mm |

| Depth | 4 in. from parting line | 101mm from parting line |

| Depth | up to 8 in. if the parting line can pass through middle of part | Up to 203.2mm if the parting line can pass through middle of part |

| Projected Mold Area | 175 sq in. (plastic) | 112,903 sq. mm (plastic) |

| Projected Mold Area | 48 sq. in. (silicone rubber) | 30,958 sq. mm (silicone rubber) |

Advantages of Insert Molding

Insert molding reduces assembly and labor costs, enhances part strength and reliability, and enables multi‑material and complex component integration.

✔️Eliminate assembly: Insert molded parts do not require assembly because there is only one manufacturing process.

✔️Reduce costs: The removal of the assembly process reduces the cost of the insert molding process compared to the standard injection molding.

✔️Reduced part size and weight: Insert molded parts weigh less than all‑metal parts.

✔️Improve part strength: Insert plastic molding securely integrates metal inserts, enhancing wear resistance and structural integrity compared to traditional assembly methods.

Applications of Insert Molding

●Consumer Goods: Custom plastic insert molding is well‑suited for consumer products, combining functional performance with aesthetic appeal.

●Medical Devices: Select biocompatible plastics and ensure regulatory compliance before using insert molding for devices and implants.

●Aerospace and Automotive: Ideal for handheld tools and control components such as screwdrivers, scissors, dials, and knobs.

●Communication Devices: Applied in aerospace, automotive, and communications for connectors, structural parts, and integrated functions, enabling lightweight and high‑reliability designs.

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.