In the field of metal precision forming, die casting technology has evolved into a diverse system including High Pressure Die Casting (HPDC), Hot Chamber Die Casting, and Cold Chamber Die Casting, each tailored to specific material and product requirements. While HPDC excels in high efficiency and mass production, and Hot/Cold Chamber Die Casting caters to different melting point metals, Low Pressure Die Casting (LPDC) stands out with its unique "low-pressure, steady filling" core advantage. As a specialized precision forming process, LPDC is mainly used to produce high-quality, low-defect metal components with complex shapes, uniform structure, and excellent mechanical properties. It is widely applied in automotive, aerospace, electrical, and other high-end manufacturing fields, filling the gap between high-pressure die casting and traditional casting, and becoming an indispensable part of the modern metal forming industry.

I. What is Low Pressure Die Casting (LPDC)?

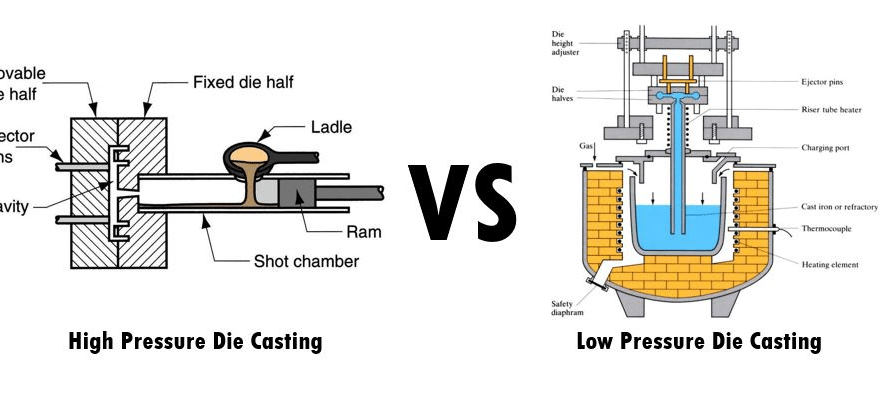

Low Pressure Die Casting (LPDC), referred to as LPDC for short, is a metal forming process that uses low-pressure gas (usually compressed air or inert gas) to push molten metal upward from the furnace into a closed mold cavity through a riser tube, and then realizes solidification and forming under constant low pressure. Its core feature is "low-pressure steady filling" — the working pressure is usually between 0.01-0.2MPa, which is much lower than the 10-150MPa of High Pressure Die Casting; the filling speed is slow and uniform (0.01-0.5m/s), avoiding the turbulence and air entrainment caused by high-speed injection in HPDC.

Different from Hot Chamber Die Casting (injection mechanism immersed in molten metal) and Cold Chamber Die Casting (injection chamber separated from furnace), LPDC adopts a "bottom-up" filling mode: the mold is installed above the furnace, and the riser tube connects the furnace and the mold cavity. The low-pressure gas acts on the surface of the molten metal in the furnace, making the molten metal rise along the riser tube at a steady speed, fill the mold cavity from bottom to top, and maintain a certain pressure during solidification to compensate for the shrinkage of the molten metal. This unique filling mode and low-pressure working condition determine that LPDC can produce components with dense internal structure, few defects, and high surface quality.

Simply put, Low Pressure Die Casting is like "slowly pouring water into a cup from the bottom up" — the molten metal fills the mold cavity smoothly under the action of low pressure, without splashing or turbulence, ensuring that every corner of the cavity is fully filled while minimizing internal defects such as air bubbles and shrinkage holes. It is especially suitable for producing medium-sized, complex-shaped metal components that require high internal quality and mechanical properties, such as automotive wheel hubs, engine cylinder heads, and aerospace structural parts.

It is worth emphasizing that LPDC is neither a branch of HPDC nor a simplified version of high-pressure die casting, but an independent die casting process with unique working principles and application scenarios. It complements HPDC: HPDC focuses on high efficiency and mass production, while LPDC focuses on high quality and low defects, forming a complementary pattern in the metal forming industry.

II. Core Structure and Working Principle of Low Pressure Die Casting

The working principle of Low Pressure Die Casting is based on the "low-pressure gas drive, steady filling, pressure-holding solidification" core logic. Its equipment structure is relatively simple compared with HPDC, but it has strict requirements on air tightness, temperature control, and pressure control. The core components and working process are as follows:

(I) Core Equipment Structure

A complete Low Pressure Die Casting system is mainly composed of five core components, which work together to ensure the stability, precision, and efficiency of the forming process. The structure is relatively unified, and there is no obvious branch like HPDC:

• Pressure-Tight Furnace: The core device for storing and melting metal raw materials, which is airtight and can withstand the low pressure (0.01-0.2MPa) required for the process. It is equipped with heating elements and temperature control systems, which can heat metal materials (aluminum alloy, magnesium alloy, copper alloy, etc.) to the specified molten state (600-1000℃) and keep the temperature stable. The furnace is usually made of high-temperature-resistant refractory materials, and the top is connected to the riser tube to realize the connection with the mold.

• Riser Tube (Feeding Tube): A connecting component between the furnace and the mold cavity, made of high-temperature-resistant heat-resistant steel. Its lower end is immersed in the molten metal in the furnace, and the upper end is connected to the sprue of the mold. The inner diameter of the riser tube is designed according to the size of the product and the filling speed, ensuring that the molten metal can rise smoothly and uniformly under low pressure.

• Mold System: Including fixed molds, moving molds, cooling channels, and ejection mechanisms, which are installed above the pressure-tight furnace. The mold cavity is processed according to the shape of the product, and the cooling channel is used to control the cooling speed and solidification sequence of the molten metal in the cavity; the ejection mechanism is responsible for ejecting the formed part from the mold cavity after cooling and solidification. The mold of LPDC has high precision, and the cavity surface is usually polished to ensure the surface quality of the product.

• Pressure Control System: The "brain" of the LPDC system, including gas source (compressed air or inert gas), pressure regulator, pressure sensor, and control panel. It can accurately set and adjust the working pressure, pressure-holding time, and pressure rise rate, ensuring that the pressure acts on the molten metal stably and uniformly. The pressure control precision is very high (error ≤ ±0.001MPa), which directly determines the filling effect and product quality.

• Mold Clamping Mechanism: Used to control the opening and closing of the mold and provide sufficient clamping force to ensure that the mold is tightly closed during the filling and solidification process. The clamping force of LPDC machines is usually between 10-500 tons, which is much lower than that of HPDC machines, and is matched with the size of the product and the working pressure. It adopts hydraulic or mechanical drive to ensure the stability of the mold during operation.

(II) Working Principle (Complete Process)

The working process of Low Pressure Die Casting is simple and easy to control, with strong stability, and the entire process can be divided into 6 standard steps, forming a cyclic production mode:

1. Metal Melting and Heat Preservation: Put metal raw materials (mainly aluminum alloy, magnesium alloy, copper alloy) into the pressure-tight furnace, heat them to the specified molten state through the heating element, and keep the temperature stable (the temperature fluctuation is controlled within ±5℃). During the melting process, inert gas (such as nitrogen, argon) can be introduced if necessary to reduce metal oxidation and remove impurities in the molten metal.

2. Mold Preparation and Clamping: Install and debug the mold, check the mold cavity for cleanliness, damage, and air tightness, and ensure that the cooling channel and ejection mechanism work normally. Then, the mold clamping mechanism drives the fixed mold and moving mold to close tightly, and applies sufficient clamping force to lock the mold, preparing for filling.

3. Pressure Application and Molten Metal Filling: Start the pressure control system, introduce low-pressure gas into the pressure-tight furnace, and the pressure acts on the surface of the molten metal uniformly. Under the action of pressure, the molten metal rises along the riser tube at a steady speed (0.01-0.5m/s), fills the mold cavity from bottom to top, and discharges the air in the cavity smoothly through the exhaust port of the mold. The filling process is slow and uniform, avoiding turbulence and air entrainment.

4. Pressure Holding and Solidification: After the mold cavity is completely filled with molten metal, the pressure control system maintains a constant low pressure (0.01-0.2MPa) to compensate for the shrinkage of the molten metal during cooling and solidification. The molten metal in the riser tube continuously supplements the shrinkage of the molten metal in the cavity, ensuring that the internal structure of the product is dense and free of shrinkage holes and air bubbles. At the same time, the cooling system works to control the solidification sequence of the product (solidify from top to bottom), improving the quality of the product.

5. Pressure Relief and Mold Opening: After the product is completely cooled and solidified, the pressure control system releases the pressure in the furnace, and the remaining molten metal in the riser tube flows back to the furnace under the action of gravity. Then, the mold clamping mechanism drives the mold to open, and the ejection mechanism ejects the formed product from the mold cavity. The ejection speed and force are precisely controlled to avoid product deformation or damage.

6. Post-Processing and Inspection: Take out the ejected product, remove the riser, gate, and burrs through post-processing (grinding, cutting, etc.), then inspect the product’s dimensional precision, surface quality, and internal defects (using non-destructive testing methods such as X-ray if necessary). Qualified products enter the next process, while unqualified products are recycled and remelted to reduce waste.

III. Process Characteristics of Low Pressure Die Casting (Advantages and Limitations)

Low Pressure Die Casting’s unique "low-pressure steady filling" and "bottom-up filling" mode give it obvious advantages in producing high-quality metal components, especially in terms of internal quality and defect control. However, compared with HPDC, it also has certain limitations in production efficiency and forming capacity. It needs to be reasonably selected according to product requirements and application scenarios.

(I) Core Advantages

1. Excellent Internal Quality, Few Defects: This is the biggest advantage of LPDC. The slow and uniform filling mode avoids turbulence and air entrainment, and the pressure-holding process effectively compensates for the shrinkage of the molten metal. The formed product has a dense internal structure, with almost no defects such as air bubbles, shrinkage holes, and oxide inclusions. The internal defect rate is less than 1%, which is far lower than that of High Pressure Die Casting (defect rate 5-10%).

2. High Mechanical Properties: Due to the dense internal structure and few defects, the mechanical properties of LPDC products are significantly higher than those of HPDC and traditional casting products. The tensile strength, yield strength, and elongation of aluminum alloy products produced by LPDC are 10-20% higher than those produced by HPDC, which can meet the performance requirements of high-load, high-reliability components.

3. Good Surface Quality and Dimensional Precision: The molten metal fills the mold cavity smoothly under low pressure, and can accurately replicate the fine structure of the mold. The surface roughness of the product can be as low as Ra≤1.6μm, and the dimensional tolerance grade can reach IT10-IT12. Most products can be directly used for assembly without a lot of post-processing, reducing production costs.

4. Low Metal Oxidation, High Material Utilization Rate: The molten metal is in a closed furnace during the entire forming process, and the contact with air is minimized, which greatly reduces oxidation and oxide inclusions. At the same time, the remaining molten metal in the riser tube can flow back to the furnace for reuse after pressure relief, and the material utilization rate can reach 90-95%, which is higher than that of HPDC (85-90%).

5. Wide Adaptability to Product Shapes: LPDC adopts bottom-up filling, which is especially suitable for producing complex-shaped components with thin walls, ribs, and multiple cavities. It can fill the narrow and complex parts of the mold cavity smoothly, avoiding the defects such as material shortage and cold shut that are easy to occur in HPDC.

6. Simple Equipment Structure, Low Maintenance Cost: Compared with HPDC machines, LPDC machines have a simpler structure, no complex high-pressure injection mechanism, and lower requirements on equipment manufacturing precision. The initial investment is moderate, and the daily maintenance is simple and convenient, which reduces the maintenance cost and workload for enterprises.

(II) Limitations

1. Low Production Efficiency, Not Suitable for Mass Production: The filling speed of LPDC is slow (0.01-0.5m/s), and the production cycle is long (each cycle takes 30-120 seconds, depending on the product size and material). The production efficiency is only 1/3-1/5 of that of HPDC, which is not suitable for large-scale mass production of small and medium-sized standard components, and is more suitable for small-batch and medium-batch production of high-quality components.

2. Limited Forming Capacity: LPDC is mainly used for producing medium-sized components, with product weight usually between 0.5-50kg and size within 1m. For extra-large, extra-heavy components (weight more than 50kg) or ultra-small components (weight less than 0.5kg), it is not suitable, and other forming processes need to be adopted.

3. Strict Requirements on Pressure and Temperature Control: The quality of LPDC products is highly dependent on the control precision of pressure and temperature. Even a small deviation in pressure (such as pressure fluctuation exceeding ±0.001MPa) or temperature (fluctuation exceeding ±5℃) may lead to product defects such as shrinkage holes and cold shut. This requires operators to have professional technical knowledge and rich operation experience, and the equipment needs to be equipped with high-precision control systems.

4. High Requirements on Mold Airtightness: The mold of LPDC must have good air tightness to prevent gas leakage during the pressure application process. If the mold is not airtight, the pressure cannot be maintained stably, which will affect the filling effect and product quality. The mold manufacturing precision and sealing performance requirements are high, which increases the mold manufacturing cost.

IV. Key Process Parameters Control of Low Pressure Die Casting

The product quality of Low Pressure Die Casting is closely related to the control of key process parameters. Due to its "low-pressure, steady filling" characteristics, the parameter control is more precise than that of HPDC, and the core parameters that need to be focused on are mainly pressure, temperature, filling speed, and pressure-holding time, which directly determine the filling effect, solidification quality, and mechanical properties of the product.

(I) Pressure Control

Pressure is the core parameter of LPDC, including pressure rise rate, filling pressure, and pressure-holding pressure, which need to be precisely controlled according to the product material and structure:

• Pressure Rise Rate: Usually controlled at 0.001-0.01MPa/s. The pressure rise rate should be slow and uniform to avoid turbulence and air entrainment caused by rapid pressure rise. For complex-shaped products, the pressure rise rate should be appropriately reduced to ensure smooth filling.

• Filling Pressure: The pressure used to push the molten metal to fill the mold cavity, usually between 0.01-0.1MPa. The filling pressure is determined by the height of the mold, the viscosity of the molten metal, and the complexity of the product. Too low filling pressure will lead to insufficient filling and material shortage; too high filling pressure will cause turbulence and air entrainment.

• Pressure-Holding Pressure: The pressure maintained after the mold cavity is filled, usually between 0.05-0.2MPa, which is slightly higher than the filling pressure. The pressure-holding pressure is used to compensate for the shrinkage of the molten metal during solidification. Too low pressure-holding pressure will lead to shrinkage holes; too high pressure-holding pressure will cause mold overflow and product deformation.

(II) Temperature Control

Temperature control is crucial for LPDC, including molten metal temperature and mold temperature, which directly affect the fluidity of the molten metal and the solidification quality of the product:

• Molten Metal Temperature: Set according to the metal material. For aluminum alloy, it is usually 650-700℃; for magnesium alloy, it is 600-650℃; for copper alloy, it is 950-1050℃. The temperature fluctuation should be controlled within ±5℃. Excessively high temperature will accelerate oxidation and increase oxide inclusions; excessively low temperature will reduce fluidity, leading to material shortage and cold shut.

• Mold Temperature: Usually controlled at 150-300℃, which needs to be kept uniform and stable. The mold temperature should be matched with the molten metal temperature and the product structure. For thick-walled products, the mold temperature can be appropriately increased to prolong the cooling time and avoid cracks; for thin-walled products, the mold temperature can be appropriately reduced to accelerate cooling and improve production efficiency. The mold temperature is adjusted through the built-in cooling channel and heating device.

(III) Filling Speed Control

Filling speed is another key parameter affecting the filling effect, usually controlled at 0.01-0.5m/s. The filling speed is determined by the pressure rise rate and the inner diameter of the riser tube, and needs to be adjusted according to the product complexity:

• For simple-shaped products with thick walls, the filling speed can be appropriately increased (0.3-0.5m/s) to shorten the production cycle;

• For complex-shaped products with thin walls and narrow cavities, the filling speed should be reduced (0.01-0.2m/s) to ensure that the molten metal fills the cavity smoothly, avoiding turbulence and air entrainment.

(IV) Pressure-Holding Time and Cooling Time Control

• Pressure-Holding Time: Usually 10-60 seconds, which is determined by the product thickness and material. Thicker products require longer pressure-holding time (30-60 seconds) to ensure that the molten metal in the riser tube can fully supplement the shrinkage of the product; thin-walled products can shorten the pressure-holding time (10-20 seconds) to improve production efficiency.

• Cooling Time: Usually 20-100 seconds, which accounts for a large proportion of the entire production cycle. The cooling time must be sufficient to ensure that the product is completely solidified before mold opening, avoiding deformation and cracks. The cooling time is adjusted through the mold cooling system, and the solidification sequence of the product (solidify from top to bottom) should be controlled to improve the internal quality.

V. Industrial Application Scenarios of Low Pressure Die Casting

Based on the core advantages of excellent internal quality, high mechanical properties, and good surface quality, Low Pressure Die Casting is mainly used for producing medium-sized, complex-shaped, high-quality metal components, and is widely applied in high-end manufacturing fields that require high product reliability and performance, such as automotive, aerospace, electrical, and medical devices. The typical application scenarios are as follows:

(I) Automotive Industry (Core Application Field)

The automotive industry is the largest application field of LPDC, mainly used for producing high-quality aluminum alloy and magnesium alloy components that require high mechanical properties and reliability, especially automotive wheel hubs, engine components, and chassis components:

• Automotive Wheel Hubs: This is the most common application of LPDC. Aluminum alloy wheel hubs produced by LPDC have dense internal structure, high strength, good impact resistance, and light weight, which can improve the safety and fuel economy of automobiles. At present, more than 80% of automotive aluminum alloy wheel hubs are produced by LPDC.

• Engine Components: Engine cylinder heads, cylinder blocks, intake manifolds, etc. These components require high temperature resistance, good sealing performance, and dense internal structure, and LPDC can effectively avoid defects such as air bubbles and shrinkage holes, ensuring the reliability of the engine.

• Chassis Components: Suspension brackets, steering knuckles, etc. These components need to bear large loads and wear, and LPDC products have high strength and durability, which can improve the safety and service life of the chassis.

(II) Aerospace Industry

The aerospace industry has extremely high requirements for the internal quality, precision, and reliability of metal components. LPDC is widely used in the production of small and medium-sized precision components of aircraft, rockets, and satellites, mainly using high-strength aluminum alloy, magnesium alloy, and copper alloy:

• Aircraft Components: Aircraft engine blades, fuel tank accessories, hydraulic system connectors, cabin structural parts, etc. These components need to have a high strength-to-weight ratio and corrosion resistance, and LPDC can ensure strict quality standards, with almost no internal defects.

• Rocket and Satellite Components: Rocket engine nozzles, satellite structural parts, etc. LPDC can form components with complex shapes and high precision, ensuring the stability of aerospace equipment during launch and operation.

(III) Electrical and Electronic Industry

The electrical and electronic industry has high requirements for the precision, surface quality, and electrical conductivity of components. LPDC is used to produce high-quality metal components of electrical equipment, mainly using copper alloy and aluminum alloy:

• Electrical Components: High-voltage switch housings, transformer cores, motor stators, etc. These components require good electrical conductivity and mechanical strength, and LPDC products have dense internal structure and good surface quality, which can meet the performance requirements.

• Electronic Equipment Components: Precision connectors, heat sinks, etc. These components require high precision and good heat dissipation performance, and LPDC can realize precision forming and ensure product consistency.

(IV) Medical Device Industry

The medical device industry has strict requirements for the precision, cleanliness, and biocompatibility of components. LPDC is used to produce small and medium-sized precision metal components of medical devices, using environmentally friendly, non-toxic, and biocompatible materials (such as medical aluminum alloy, titanium alloy):

• Diagnostic Equipment Components: Medical imaging equipment brackets, detection probe housings, etc. These components require high precision and no internal defects to ensure the accuracy of diagnostic results.

• Surgical and Rehabilitation Equipment Components: Surgical instrument handles, prosthetic structural parts, wheelchair frames, etc. These components require high strength, good corrosion resistance, and smooth surfaces, which are perfectly matched with LPDC’s process advantages.

(V) Other Fields

In addition to the above fields, LPDC is also widely used in hardware tools, marine engineering, and other fields:

• Hardware Tools: High-precision tool bodies, gears, etc., which require high strength and wear resistance.

• Marine Engineering: Marine engine components, ship hull connectors, etc., which require good corrosion resistance and high strength.

VI. Development Trends of Low Pressure Die Casting

With the continuous development of global manufacturing towards high quality, precision, greenization, and intelligence, Low Pressure Die Casting, as a high-quality metal forming process, is constantly upgrading and optimizing, breaking through existing limitations (such as low production efficiency), and expanding application boundaries. In the future, it will mainly show the following four development trends:

(I) Intelligence and Automation Upgrade

The integration of industrial robots, machine vision, AI algorithms, and high-precision control systems will make LPDC realize full-process intelligent production. Intelligent control systems can real-time monitor and adjust pressure, temperature, filling speed, and other parameters, automatically optimize the process parameters according to the production status, and predict and diagnose faults. At the same time, automated production lines will replace manual operations in mold clamping, part taking, post-processing, and inspection, improving production efficiency and product consistency, and reducing labor costs.

(II) Improvement of Production Efficiency

To solve the problem of low production efficiency, researchers will optimize the LPDC process and equipment structure: on the one hand, improve the pressure and filling speed control precision, shorten the filling and pressure-holding time; on the other hand, develop multi-cavity molds and continuous production equipment, realize one-time forming of multiple products, and improve production efficiency. It is expected that the production efficiency of LPDC will be increased by 50-100% in the future, narrowing the gap with HPDC.

(III) Green and Energy-Saving Transformation

Under the background of global carbon neutrality, green and energy-saving has become an important development direction of LPDC. Energy-saving heating elements and heat insulation materials will be widely used to reduce energy consumption during the melting process; inert gas recycling technology will be developed to reduce gas consumption; molten metal recycling technology will be optimized to improve the material utilization rate; and environmentally friendly fluxes and protective gases will be used to reduce environmental pollution, realizing green production.

(IV) Expansion of Material and Application Boundaries

With the development of material science and mold technology, LPDC will gradually expand the applicable material range, and can process high-performance special alloys (such as titanium alloy, high-strength steel) that were difficult to process in the past, meeting the needs of high-end fields such as aerospace and military industry. At the same time, it will expand to new fields such as new energy (wind power, photovoltaic) and 3C electronics, and develop towards large-scale and ultra-precision forming, further expanding the application space.

VII. Conclusion

In the diverse system of metal precision forming technology, Low Pressure Die Casting (LPDC) relies on its unique "low-pressure steady filling" core advantage, showing obvious advantages in producing high-quality, low-defect metal components. Compared with High Pressure Die Casting, it has better internal quality and mechanical properties; compared with traditional casting, it has higher precision and surface quality. It fills the gap between high-pressure die casting and traditional casting, and becomes an indispensable part of the modern metal forming industry.

Although LPDC has limitations in production efficiency and forming capacity, with the continuous integration of intelligence, automation, and new technologies, these limitations are gradually being broken. In the future, LPDC will develop towards higher quality, higher efficiency, greener, and more intelligent directions, providing high-quality, high-reliability forming solutions for automotive, aerospace, and other high-end manufacturing fields. It will not only promote the upgrading and development of the metal forming industry but also play an important role in the global manufacturing transformation and upgrading, helping the manufacturing industry move towards high-end, high-value-added, and sustainable development. For enterprises, mastering the core technology and parameter control of LPDC will become the key to enhancing core competitiveness and seizing market opportunities in the high-end component manufacturing field.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.