Magnesium Die Casting

with Mastars

Magnesium Die Casting: Where Lightweight Meets Uncompromised Durability.

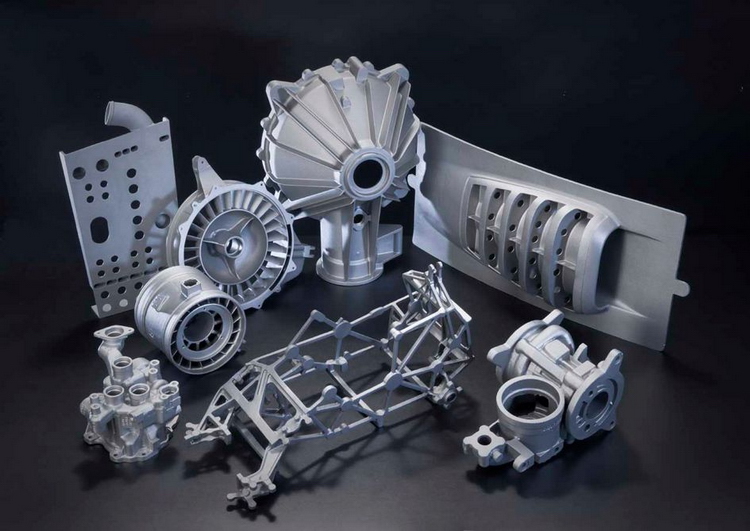

Magnesium Die Casting

Magnesium die casting is a manufacturing process that involves injecting molten magnesium into a mold—whose cavity mirrors the negative shape of the desired part—to form components. It shares similarities with other casting methods, where liquid material fills a cavity to replicate the target product’s form.

Magnesium alloys are melted either in the die-casting machine or a separate furnace. The molten material is then either gravity-fed into the mold to solidify or forced into it and held under high pressure via a hydraulic press (pressure die casting). Once the material solidifies and takes the part’s shape, the mold opens, and the component is removed manually or automatically.

Applications of Magnesium Die Casting

Why Choose Mastars

Endless Options

Easy to Use

Vetted Network

Types of Magnesium Die Casting

There are two main types of die casting: hot chamber and cold chamber. Magnesium alloys can be die cast using either process. The two methods are described in more detail below:

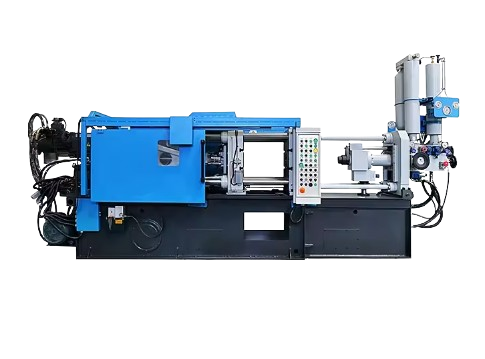

Hot Chamber Die Casting

Hot chamber die casting, also called "gooseneck casting", is a common die casting method. One end of a gooseneck-shaped channel is immersed in a closed molten metal bath, and the nozzle is heated to 400–500 °C (via gas, electric or induction heating) to prevent metal solidification. During the process, a hydraulic piston pushes molten metal from the bath through the gooseneck into the cavity. It is mainly suitable for low-melting-point metals (zinc, tin, lead, 450°F–787°F) and can also be used for magnesium (around 1100°F).

This method reduces molten metal's exposure to air, preventing oxide inclusions with the protection of a cover gas (usually sulfur hexafluoride). Hot chamber magnesium die casting is ideal for mass production due to shorter cycle times—integrated furnace and casting parts eliminate the need for molten metal transportation and superheating required in cold chamber casting. However, it produces more porous parts (due to high injection velocity trapping gas) and is more costly than cold chamber casting, as continuous high-temperature exposure causes equipment corrosion and higher long-term maintenance costs.

Cold Chamber Die Casting

Cold chamber die casting melts metal in a separate furnace, pouring the molten metal into an unheated chamber for high-pressure injection into the mold. It is ideal for high-melting-point metals like magnesium, aluminum, and copper. Similar to hot chamber casting, a cover gas is used to protect molten magnesium and prevent oxide formation.

This method is more cost-effective due to lower maintenance needs but has longer cycle times and potentially lower product quality—high pressure may trap gases before solidification. While magnesium alloys suit both processes, cold chamber is more common for magnesium casting, as integrated hot chamber machinery is expensive; manufacturers typically melt magnesium separately and transfer it to the die-casting machine.

Magnesium Alloy Properties

We don't have MOQ, only 1pcs is according to high standard to make, we pursuit the product is perfect to every customer, from 1pcs to million,we are glad to witness and grow together with our customers, that make us proud.

| Magnesium Alloy | Density | Yield Strength | Elongation | Elastic Modulus | Melting Temperature |

| AZ91D | 1.81 g/cm3 | 160 MPa | 3% | 45 GPa | 875-1105 °F |

| AZ91HP | 1.81 g/cm3 | 160 MPa | 3% | 45 GPa | 875-1105 °F |

| AM60B | 1.80 g/cm3 | 130 MPa | 8% | 45 GPa | 1005-1140 °F |

Applications of Magnesium Die Casting

Industries

TECHNOLOGY

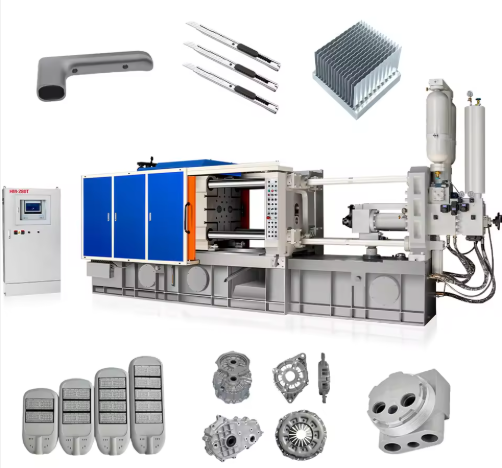

We provide multiple Magnesium die casting technologies, including but not limited to:

Multi-Slide Die Casting

Conventional Die Casting

Parts range from 5 grams to several kilograms, with a tonnage range of 60-580T, and the equipment features thrusters, flexible crosshead adaptor systems, and fast pneumatic injection.

Hot Chamber Die Casting

Our automated multi-slide and conventional machines—featuring internal melting pots, aluminum hot chamber capability, and up to 6 slides for complex geometries—are ideal for low melting-point alloys.

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.