Aerospace Manufacturing Services

Mastars’ aerospace prototype contract manufacturing utilizes advanced technologies (CNC, 3D printing, vacuum casting) and strict QC. Specializing in high-precision (±0.2mm) aerospace-grade materials (titanium, superalloys, carbon fiber), it holds AS9100 certification and offers integrated post-processing, meeting R&D verification standards for avionics, engines, and satellite components.

As a key aerospace R&D partner, Mastars delivers 7-day fast prototyping via CAD/CAM digital control. Covering suborbital vehicles, satellite payloads, and aero-engines, it provides single-component and integrated prototypes with traceable QA reports, satisfying strict supply chain requirements for enterprises’ R&D and pilot production.

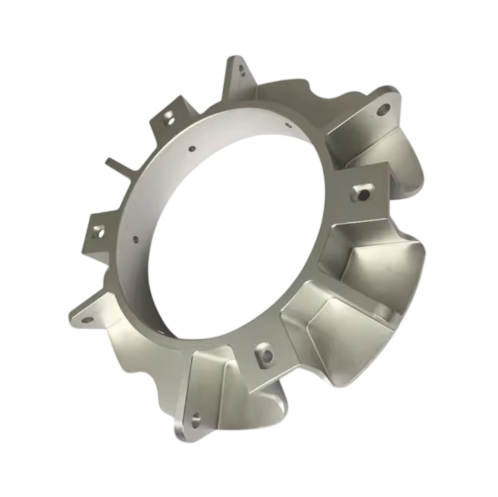

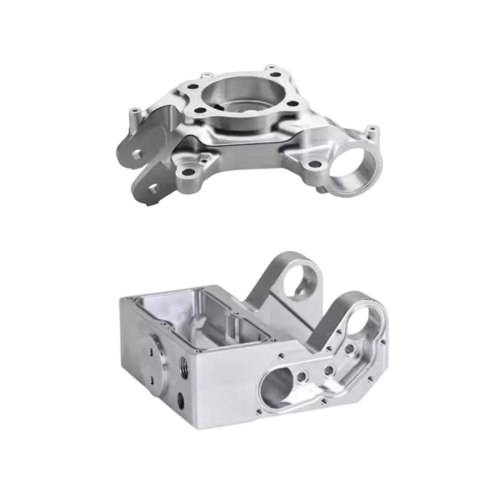

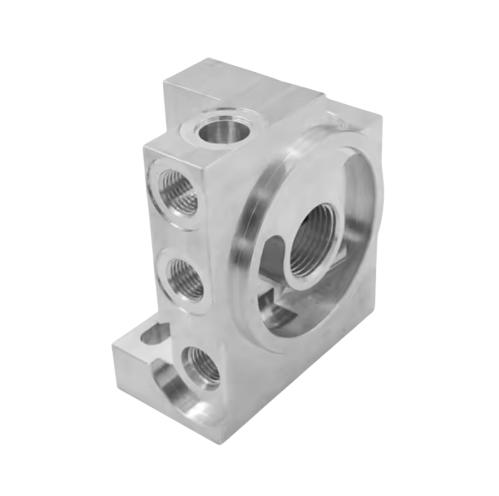

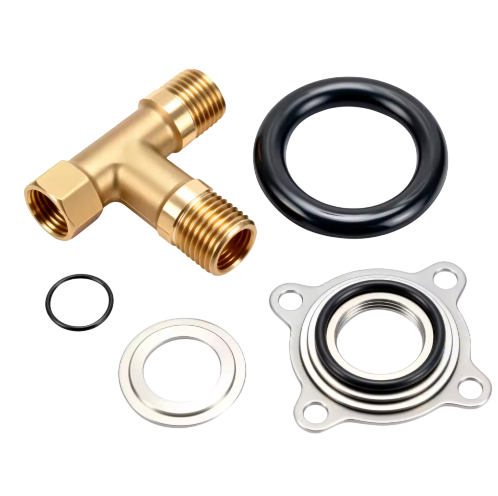

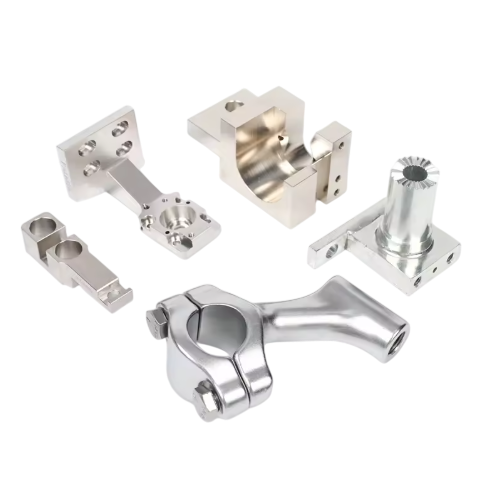

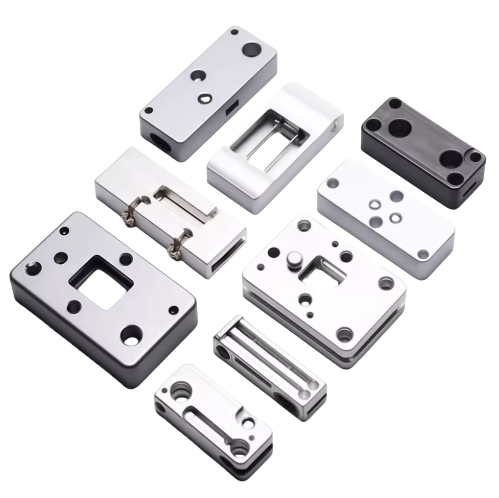

Aerospace Parts Mastars Serves

Quality Measures

We don't have MOQ, only 1pcs is according to high standard to make, we pursuit the product is perfect to every customer, from 1pcs to million,we are glad to witness and grow together with our customers, that make us proud.

Backed by industry-standard certifications and rigorously validated procedures, we deliver assured quality and unwavering regulatory compliance.

| CMM inspection report | First Article Inspection (FAI) |

| Dimensional Inspection Report (DIR) | PPAP |

| Material Certificates + Certificate of Analysis | Conflict Minerals Reporting |

| REACH + RoHS Certificates | Prop65 |

| Industry Certifications: ISO 9001 and AS 9100 | Certificate of Conformance (CoC) |

| Industry Certifications | ISO 13485, ISO 14001, ISO 45001, and ISO TS16949 |

Materials for Aerospace Components

Titanium

Aluminum

Inconel

Stainless Steel

Liquid Silicone Rubber

Choose our fluorosilicone when you need dependable fuel and oil resistance; opt for our optical silicone rubber as a robust PC/PMMA substitute.

Top Aerospace Applications

✔️ End-use production of flightworthy components with high-precision tolerances

✔️ Customized small production runs for repairs or replacement

✔️ Rapid tooling, jigs, brackets and chassis for manufacturing

✔️ Custom tooling

✔️ Rapid prototyping of parts using 3D printing with metals and plastics

✔️ Rapid prototyping of parts using CNC machining

✔️ Custom fixturing

✔️ Fit check gauges

✔️ Composite tooling

Innovative Drone Development

Powered by 5‑axis machining and high‑speed milling, Mastars provides end‑to‑end precision manufacturing for UAVs—from airframes, powertrain and landing gear to optical pods—in aluminum, titanium, high‑temperature alloys and carbon‑fiber‑reinforced composites. We combine lightweight strength, high reliability and tight tolerances to accelerate prototyping and scale to volume production with confidence.

From NPI to mass production, our integrated workflow covers programming, simulation, fixturing, CNC machining and metrology, ensuring dimensional stability and full traceability. With the flexibility to handle small batches and ramp up efficiently, we help UAV programs move from concept to delivery with speed, consistency and quality.

Aerospace Post-Processing Capabilities

✔️ Anodizing

✔️ Passivization

✔️ Electroplating

✔️ Powder Coating

✔️ Insert Installation

✔️ Heat Treatment

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.