Custom CNC Turning

with Mastars

1-day fast lead times, competitive pricing.

CNC Turning with Mastars

Leverage our on-demand CNC turning service for reliable metal and plastic turned parts. With advanced technologies and expert technicians, RapidDirect delivers high-accuracy custom prototypes and end-use parts—regardless of complexity—with deliveries as fast as one day.

Our precision lathes (equipped with live tooling for holes, slots, flats) produce cost-effective simple/complex cylindrical geometries. Full automation enables faster, easier, low-cost production of hundreds of consistent parts.

Mastars' CNC Turning Parts

Custom CNC Machining Materials

✔️ Aluminum

·Aluminum 5052 ·Aluminum 7075 & 7075-T6 ·Aluminum 6063-T5 ·Aluminum 7050-T7451 ·Aluminum MIC-6 ·Aluminum 6061-T6 ·Aluminum 2024-T3

✔️ Copper

·EPT Copper C110 ·Copper 101

✔️ Bronze/Brass

·Brass C360 ·Brass 260 ·C932 M07 Bearing Bronze

✔️ Plastics

·ABS ·Acetal [Delrin] ·Acrylic ·G-10 Garolite ·Nylon 6/6 ·PEEK ·Polycarbonate ·PTFE [Teflon] ·Polypropylene ·Ultra-High Molecular Weight Polyethylene

✔️ Steel / Titanium / Zinc

·Alloy Steel 4130 ·4140 ·ASTM A36 ·Stainless Steel 15-5 17-4 18-8 303 ·Stainless Steel 303 304 316/316L ·Stainless Steel 416 420 ·Low Carbon Steel ·Steel A36 ·Titanium Grade 2 ·Titanium 6Al-4V ·Zinc Sheet Alloy 500

Applications of CNC Turning

CNC Turning is widely used to produce a variety of precision parts:

· Shafts: Core machine axes/pivots requiring precise diameter and surface finish for mechanical fitting.

· Flanges: Pipe/pump/valve connectors needing accurate machining to ensure secure, leak-proof joins.

· Shafts: Core machine axes/pivots requiring precise diameter and surface finish for mechanical fitting.

· Bushings & Sleeves: Smooth contact components with strict internal diameter and finish requirements for part movement.

· Pins: Small but critical alignment/fastening parts requiring precise dimensions for snug fits.

· Knobs & Dials: User interface elements where precise dimensions and aesthetics boost usability.

· Wheels & Rollers: Conveyor system components needing consistent shape and smoothness to reduce friction and wear.

Our Ideas Have Helped Clients Bring Hundreds Of Products To Market

CNC Turning Design Guidelines

| Recommended Size | ||||

| Radii | Internal radii should be at least 1/3 of the cavity depth. Use larger radii whenever possible. | |||

| Threads and Tapped Holes | External and internal threads can be precisely cut. Standard thread sizes from M1.6 and larger are feasible. | |||

| Ensure a minimum thread length of 1.5 times the diameter for stability. | ||||

| Minumum Wall Thickness | Maintain a minimum wall thickness of 0.8 mm for metals and 1.5 mm for plastics to ensure structural integrity without compromising the machining process. | |||

| Text | Engraving should have a minimum character height of 2 mm and a depth of at least 0.5 mm to ensure legibility after machining. | |||

| Holes | Minimum hole diameter of 0.5 mm. For deep holes, maintain a diameter to depth ratio of 1:10 to avoid tool deflection and ensure hole quality. | |||

Available Finishes

✔️ As-Milled

This fastest-turnaround surface finish option features visible tool marks, possible sharp edges and burrs (removable upon request), with a roughness equivalent to 125 uin Ra.

✔️ Bead Blast

The part surface is media blasted, typically using glass bead, to produce a smooth, matte appearance.

✔️ Anodized (Type II Or Type III)

Type II anodization (aluminum-only) offers corrosion resistance and common colors (clear, black, red, gold). Type III is thicker, with both corrosion and wear resistance.

✔️ Powder Coat

Powder coating sprays paint powder on parts, then cures in an oven. It forms a wear/corrosion-resistant layer—tougher than standard paint—with diverse color options.

✔️ Custom

Don’t see the finish you need? Submit an RFQ and we’ll look into a finishing process for you.

Advantages of CNC Turning

CNC turning offers numerous advantages for manufacturing:

· Precision: Tight tolerances for seamless complex assembly integration

· Efficiency: Programmed automated production, fast and consistent with minimal supervision

· Flexibility: Quick reprogramming adapts to diverse production needs

· Repeatability: Automated mass production ensures identical part quality

· Cost-Saving: Less manual labor cuts costs and reduces human error

· Material Versatility: Handles metals, plastics, composites and more

· Safety: Enclosed automation minimizes workplace accident risks

Quick links

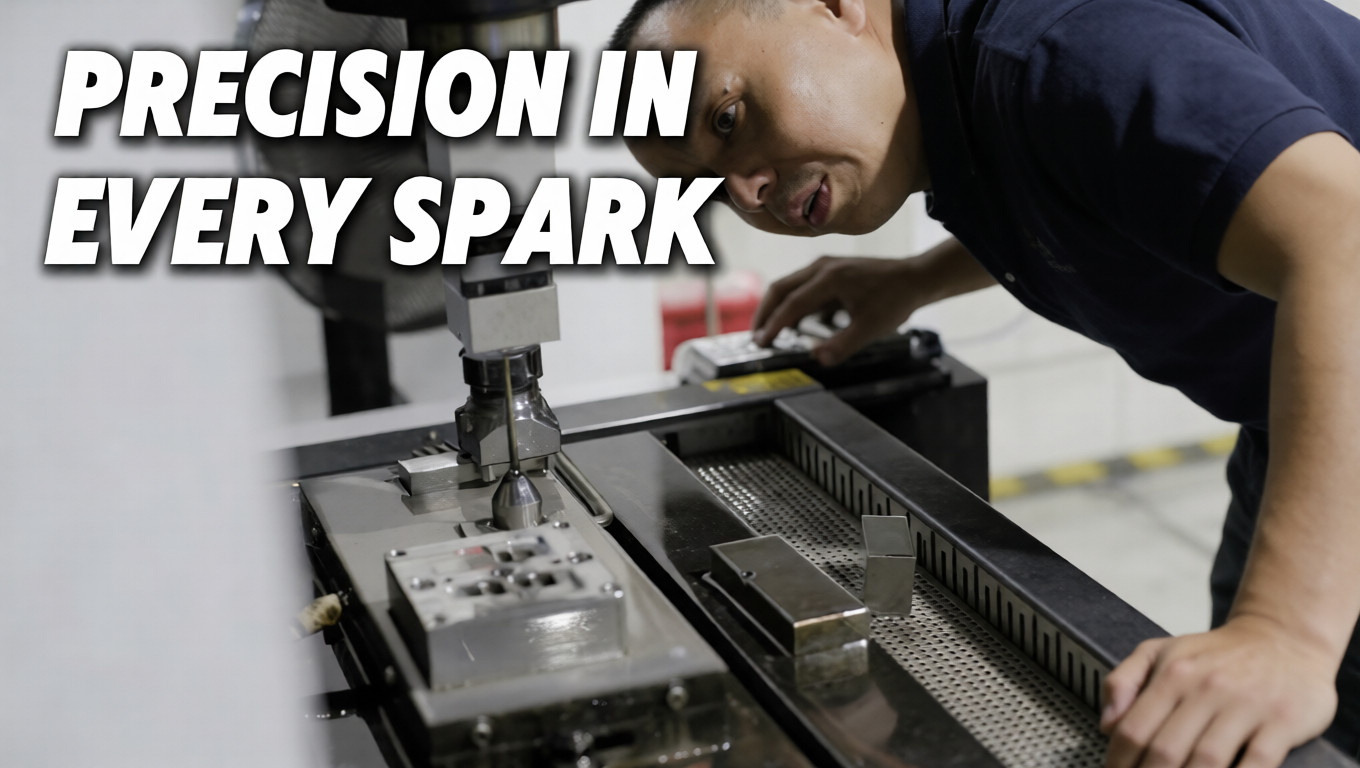

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.