Automotive Prototyping & Manufacturing Services

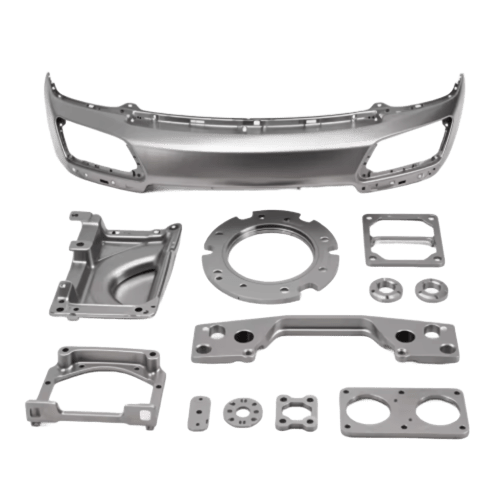

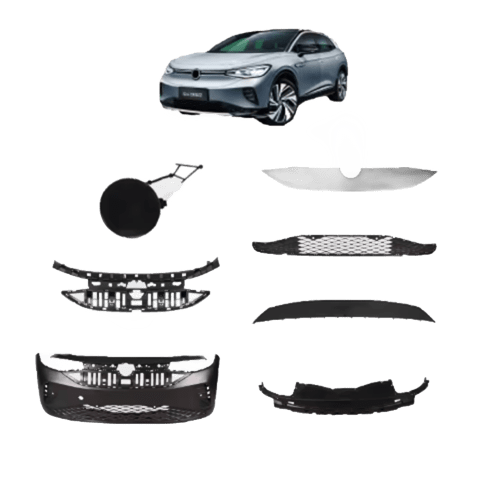

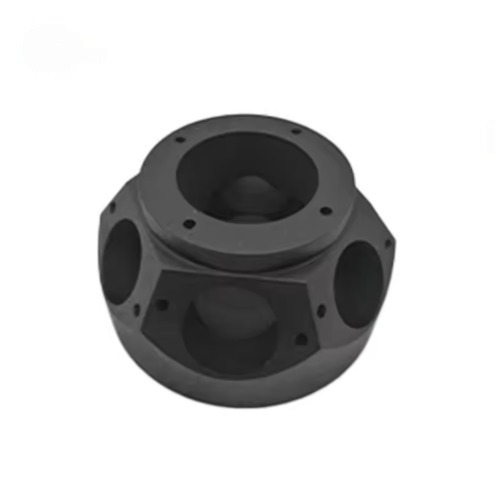

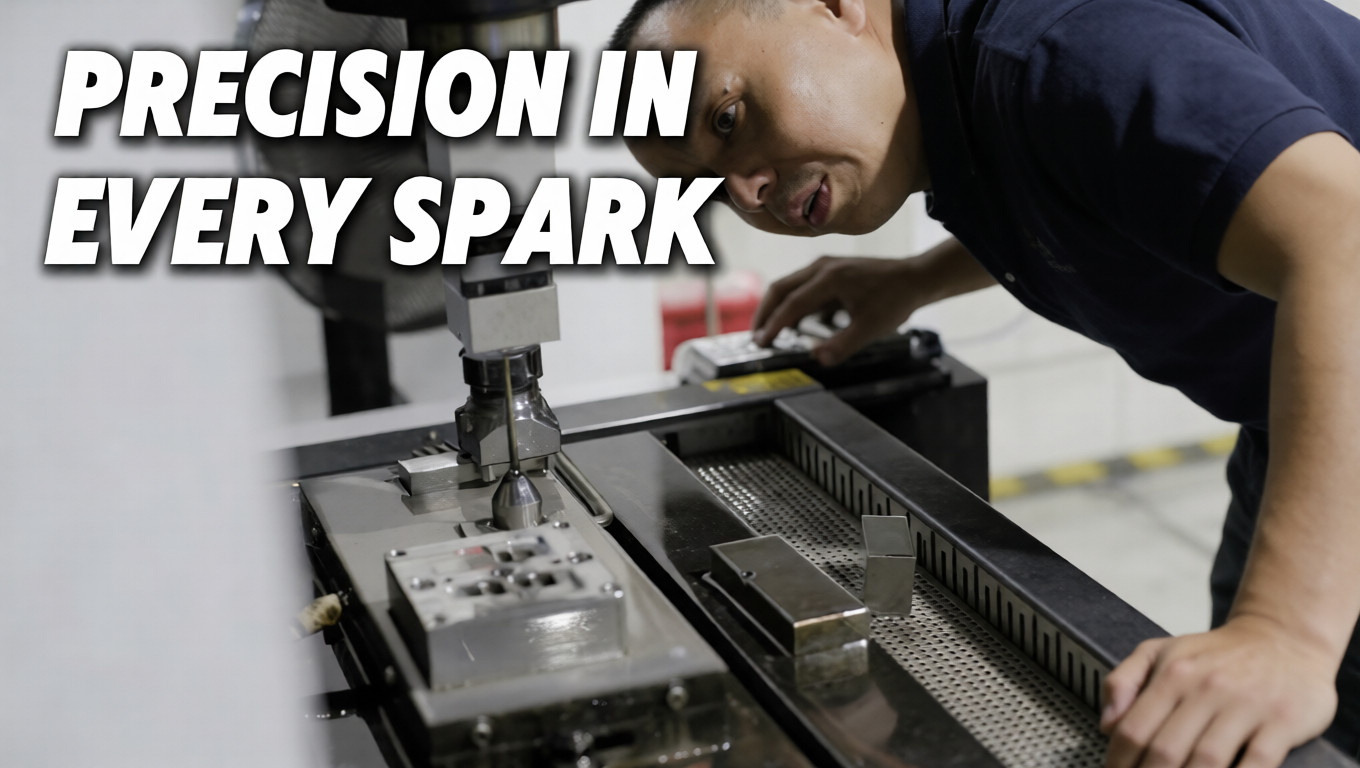

Mastars provides OEM/ODM automotive contract manufacturing from DFM/concept to prototyping, tooling, pilot, and high‑volume production. We coordinate CNC, metal stamping/welding, sheet metal, injection molding, and die casting with in‑house tooling/inspection. Our quality system—IATF 16949, APQP/PPAP, MSA/SPC, 8D, and full traceability—ensures compliance and reliability. With automated/semi‑automated lines, EOL testing, and process audits, we tailor cycle time/capacity, support JIT/JIS and VMI, and serve structural/appearance/functional parts across small/medium/high volumes to shorten lead time, reduce TCO, and enable stable on‑time delivery.

Backed by a cross‑disciplinary engineering team and digital manufacturing, Mastars applies DFM/DFMEA and analysis such as mold flow, topology optimization, and tolerance chain to strengthen design robustness. In production, we run Cp/Cpk studies, incoming/in‑process/final inspection, and reliability validation (lifetime, environmental, vibration, sealing). MES enables real‑time data collection, traceability, and alerts. We deliver PPAP, full‑dimensional reports, and material/performance certificates, support ECN/ECR change control and annual audits, ensuring a seamless ramp‑up from pilot to mass production with high consistency, full traceability, and rapid response.

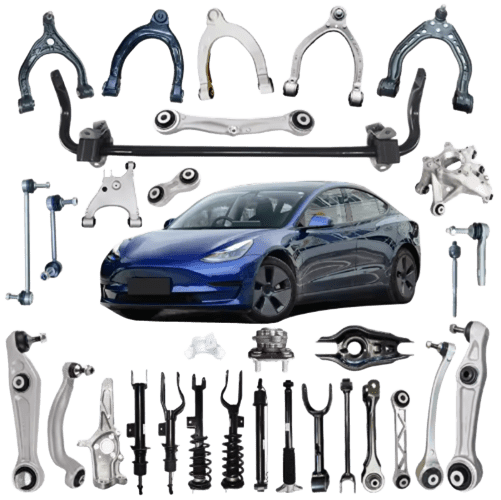

Robotic Parts Mastars Serves

Our Ideas Have Helped Clients Bring Hundreds Of Products To Market

Quality Measures

| CMM inspection report | First Article Inspection (FAI) | |||

| Dimensional Inspection Report (DIR) | PPAP | |||

| Material Certificates + Certificate of Analysis | Conflict Minerals Reporting | |||

| REACH + RoHS Certificates | Prop65 | |||

| Industry Certifications: ISO 9001 and IATF 16949 ISO 13485 | Certificate of Conformance (CoC) | |||

Materials for Automotive Applications

✔️ Thermoplastics

Select from a broad portfolio of thermoplastics including PEEK and Acetal, or provide your own material. We support custom color matching on approved programs to preserve your brand identity.

✔️ Nylons

We 3D print functional prototypes in multiple nylon materials using SLS and MJF. For higher mechanical performance, select glass‑filled or mineral‑filled nylons to enhance strength and durability.

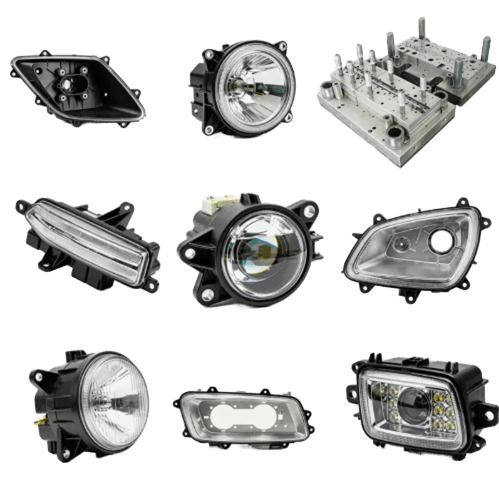

✔️ Liquid Silicone Rubber

Silicone rubber grades—including fuel‑resistant fluorosilicone—are suitable for gaskets, seals, and tubing; an optical‑clarity grade is available for lens and lighting applications.

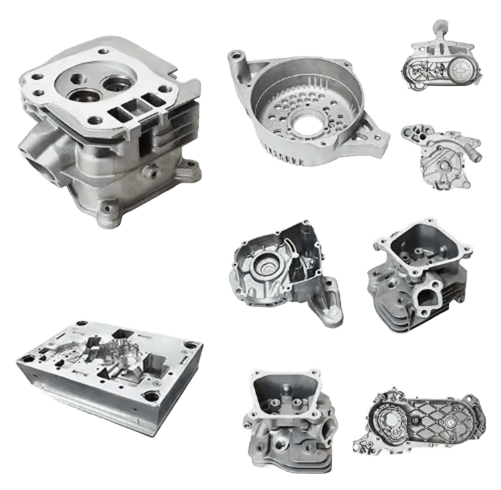

✔️ Aluminum

This all‑purpose metal enables lightweight designs with an outstanding strength‑to‑weight ratio and supports machining or additive manufacturing (3D printing).

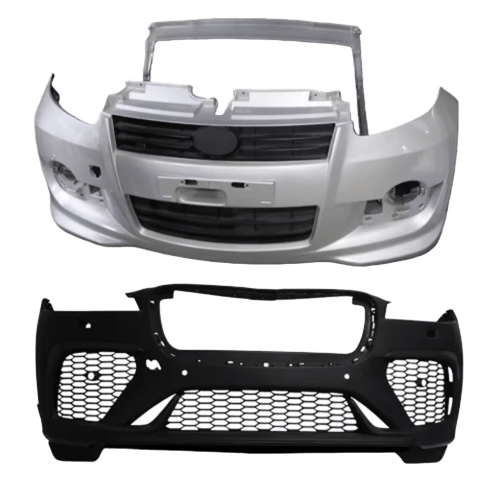

Top Precision Automotive Applications

✔️ Low volume prototype, pilot, or short-term production support using: Injection molding, Urethane casting, Small part stampings

✔️ Production parts supply: Bridge tooling & parts supply, Low to medium volume tooling parts supply, Service parts supply using new or existing tooling

✔️ Rapid prototyping with: Additive manufacturing, CNC machining

✔️ Plant floor manufacturing support: Custom assembly fixtures/equipment/jig details, Custom check fixture or part check details

Precision Manufacturing for Automotive Industry

Mastars provides one‑stop tooling and prototype services for the automotive industry, supporting OEMs and Tier‑1/Tier‑2 suppliers from DFM and prototyping to soft molds, trial molding, and fixtures/jigs. Built on IATF 16949, ISO 9001, APQP/PPAP, MSA/SPC, and 8D problem‑solving, we ensure high consistency, traceability, and on‑time delivery for DV/PV validation and smooth ramp‑up.

Our prototyping and trial‑production capabilities cover CNC machining, 3D printing (SLA/MJF/SLS), silicone molding, and vacuum casting for appearance, structural, and functional validation. We also offer aluminum/simplified steel rapid tooling for EP/E‑sample builds and small‑batch runs, with fixtures/jigs development and validation. Materials include engineering plastics (ABS/PC/PP/PA/PMMA/POM), metals (aluminum/magnesium/steel), and elastomers (silicone/rubber), supported by painting, silk‑screening, electroplating, brushing, anodizing, laser engraving, and assembly. Quality and delivery include in‑process/final inspection, Cp/Cpk studies, reliability testing (life, environmental, vibration, sealing), and full MES traceability to meet small/medium/large volume needs and accelerated timelines.

Automotive Post-Processing Capabilities

✔️ Anodizing

✔️ Passivization

✔️ Electroplating

✔️ Powder Coating

✔️ Insert Installation

✔️ Heat Treatment

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.