Medical Devices Manufacturing Services

Mastars provides end‑to‑end OEM/ODM for Medical Devices, from DFM and rapid prototyping to tooling, injection molding and metal machining, cleanroom assembly, functional testing, and global delivery. With scalable capacity and fast iteration, we help medical OEMs accelerate time‑to‑market while maintaining full traceability, process validation, and regulatory readiness across Class I–III programs.

Our quality system is built on ISO 13485, supported by IQ/OQ/PQ validation, process controls, and risk management to ensure dimensional stability, reliability, and cleanroom integrity for critical devices and components. From single‑use disposables to reusable instruments and diagnostic equipment, we deliver customized solutions, low‑friction finishes, and complex geometries with seamless supply‑chain integration and on‑time delivery.

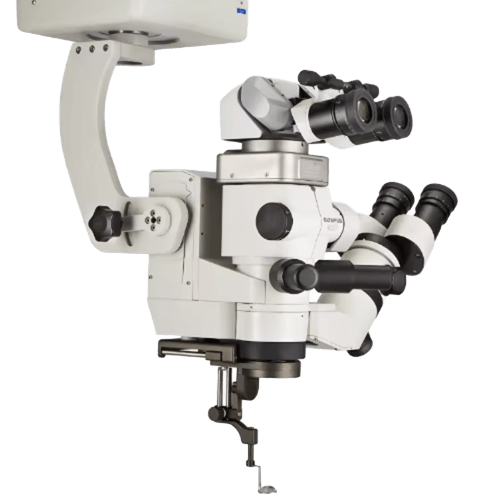

Medical Parts Mastars Serves

Our Ideas Have Helped Clients Bring Hundreds Of Products To Market

Quality Measures for the Medical Industry

| CMM inspection report | First Article Inspection (FAI) | |||

| Dimensional Inspection Report (DIR) | PPAP | |||

| Material Certificates + Certificate of Analysis | Conflict Minerals Reporting | |||

| REACH + RoHS Certificates | Prop65 | |||

| Industry Certifications: ISO 9001 and AS 9100 | Certificate of Conformance (CoC) | |||

Materials for Medical Applications

✔️ High-temp Plastics

PEEK and PEI (Ultem) combine high‑temperature resistance with creep resistance, making them ideal for sterilization‑required applications.

✔️ Medical-grade Silicone Rubber

With excellent thermal, chemical, and electrical resistance, Dow Corning QP1‑250 is biocompatible and appropriate for use where skin contact occurs.

✔️ Advanced Photopolymers

Tough Black and ceramic‑filled are production‑grade materials available via our Hybrid PhotoSynthesis (HPS) technology, ideal for late‑stage prototyping and end‑use devices.

✔️ Microfluidics

Watershed (ABS‑like) and Accura 60 (PC‑like) are transparent, production‑grade materials suitable for microfluidic parts and transparent components such as lenses and housings.

✔️ Medical Alloys

Machined metals, 3D‑printed metals, and sheet metal together provide 20+ metal material options for medical components and other applications.

Top Medical Devices & Hardware Applications

✔️ Ventilator parts

✔️ Models for clinical training and surgical planning

✔️ Highly variable, low-volume production runs with high-precision tolerances

✔️ Custom tooling brackets and chassis for medical manufacturing

✔️ Rapid prototyping of medical devices using additive manufacturing

✔️ Rapid prototyping of medical devices using CNC machining

✔️ Custom fixturing

✔️ Personal protective equipment (PPE)

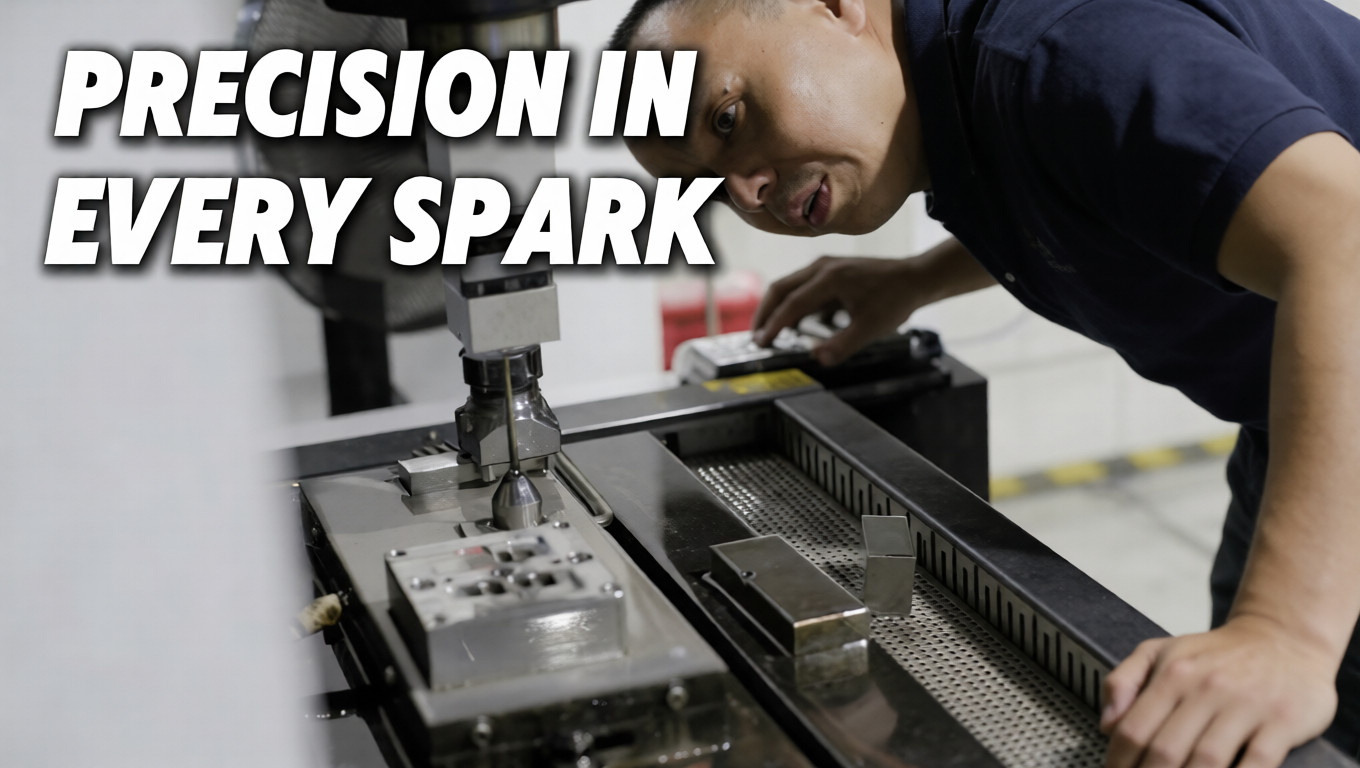

Your Trusted Partner for Medical Products Development

Built‑in speed, quality, and deep technical expertise drive our end‑to‑end process. Collaborating with us ensures your design is refined, your time‑to‑market is shortened, and you’re supported from prototyping to production.

Medical Post-Processing Capabilities

✔️ Anodizing

✔️ Passivization

✔️ Electroplating

✔️ Powder Coating

✔️ Insert Installation

✔️ Heat Treatment

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.