Industrial Equipments Prototyping and Manufacturing Services

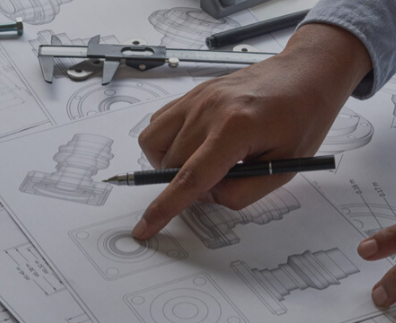

Mastars provides end‑to‑end OEM/ODM for Industrial Equipments, from prototyping and tooling to injection molding/metal machining, assembly, testing, and global delivery. With cost‑effective, responsive capacity in plastics and metals, we support low‑volume pilots to scalable mass production, helping you launch and iterate faster with lower risk.

For OEM projects, we combine engineering consultation and DFM with supply‑chain integration and quality management. Our rigorous processes and one‑stop solutions ensure dimensional stability, reliability, and seamless fit across complex assemblies, while enabling customization, low‑friction finishes, and complex geometries to balance performance, cost, and lead time.

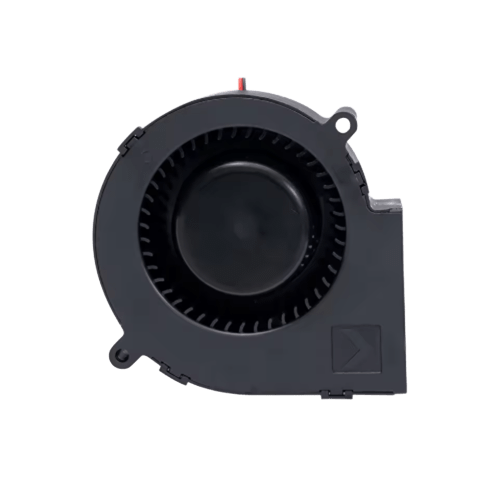

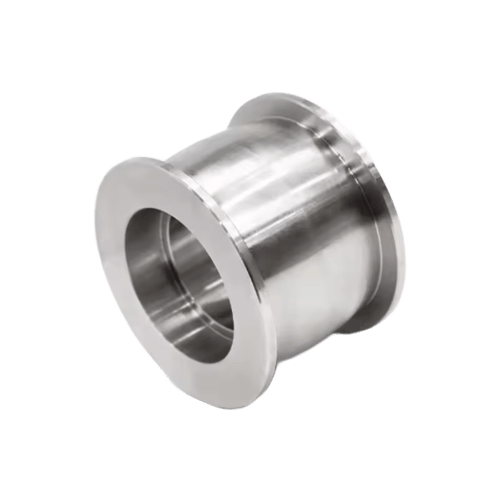

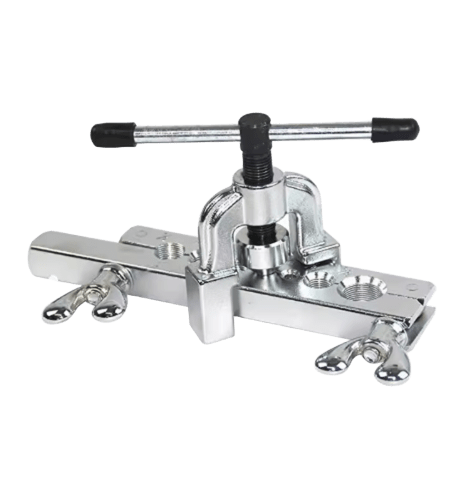

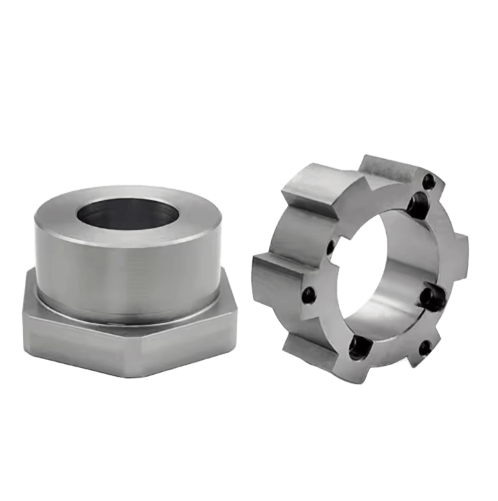

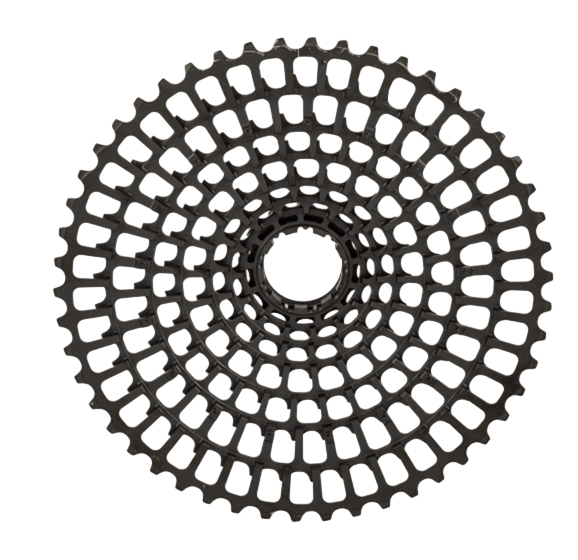

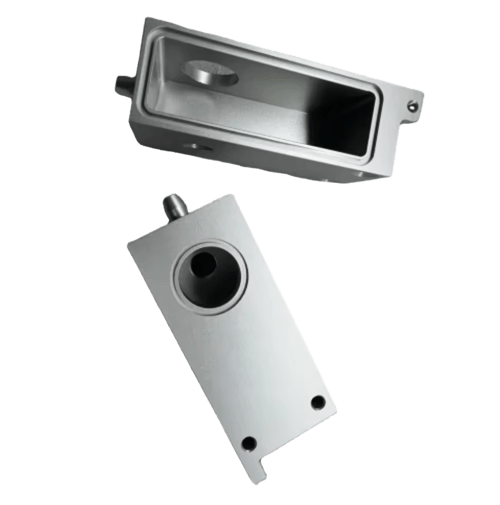

Industrial Equipments Parts Mastars Serves

Materials Options

We offer a huge range of material possibilities with all our manufacturing processes. Some common choices for industrial machinery are listed below.

✔️Steel ✔️Aluminum ✔️Titanium ✔️Silicone

✔️PA(Nylon) ✔️PMMA ✔️PVC ✔️POM ✔️PP

Common Industrial Applications

✔️ Machine and tool parts

✔️ Jigs and fixtures

✔️ Electronic housings

✔️ Pumps and accessories

✔️ Oil and gas extraction equipment

✔️ General industrial machinery

✔️ Conveyors and conveying equipment

✔️ Parts for tractors, bulldozers, forklifts, and other heavy construction and individual vehicles and equipment

Industrial Equipment Solutions

Common challenges for industrial equipment makers? Our seasoned engineering & production staff have the solutions.

✔️ Design for manufacturability (DFM)

✔️ Optimization for advanced applications

✔️ Part consolidation

✔️ Lightweighting

✔️ Eliminating or simplifying tooling

✔️ Reducing lead time on parts

✔️ Cost reduction

✔️ Providing on-demand production of service parts

Applicable Finishes for Industrial Machinery

Mastars delivers a wealth of premium surface finishes. We list only common options with more custom finishes available for industrial machinery parts.

✔️As-machined Base Finish: As machined

✔️Mechanical Abrasive Finishes: Sanding & Polishing, Sand, Bead Blasted

✔️Coating Finishes: Painted, Powder coat

✔️Electrochemical & Chemical Conversion Finishes: Anodized, E-Coating, Chromate Conversion Coating

✔️Electroplating Finishes: Nickel Plating, Chromed, Zinc Plating

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.