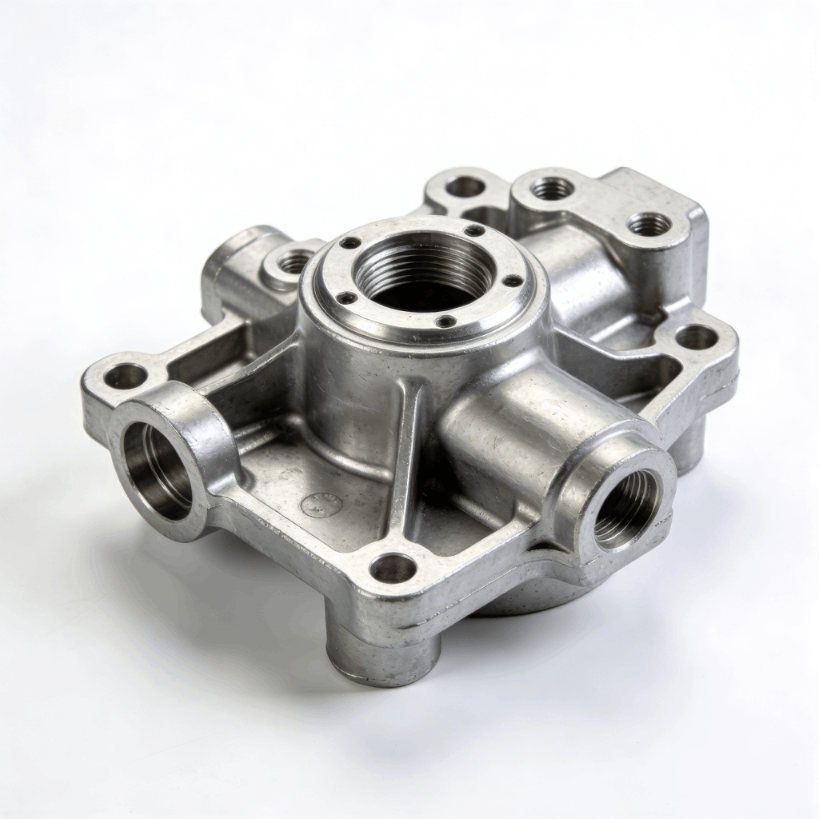

Pressure Die Casting

with Mastars

Tool manufacturing in up to 12-20 days, Ideal for serial production of metal parts

What is Pressure Die Casting?

Die casting is a manufacturing process that utilizes steel molds for the high-volume production of complex metal parts. By injecting molten low-melting-point metals such as aluminum and zinc into the mold cavity under high pressure, this process enables rapid formation of parts with high precision, excellent surface quality, and intricate geometries. Cycle times can range from less than a second to several minutes, making it highly suitable for mass production.

With over 20 years of experience in zinc and aluminum die casting, Mastars possesses technical expertise in both hot-chamber and cold-chamber die-casting processes. Through continuous improvement in alloys and processes, the company applies die-casting technology across various market sectors, providing components that excel in both performance and visual appeal for designers.

Advantages of Die Casting with Mastars

Advantages of Die Casting with Mastars

Rapid Turnaround

Endless Options

In-house quality control

Serial Production

Ideal for the production starting from 100 parts.

Our Ideas Have Helped Clients Bring Hundreds Of Products To Market

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.