Communication Industry Prototyping and Manufacturing Services

Aligned with the 5G industry chain, Mastars offers one‑stop PCB/PCBA and NPI from prototyping to production: high‑layer PCBs for RRU/AAU and small cells; SMT and precision assembly of PA/LNA/FEM; machining and assembly of antenna arrays and RF connectors; BBU/ODU integration; system‑level testing and environmental reliability. Backed by ISO 9001 and ESD/cleanroom controls, we support prototyping → pilot → mass production for Massive MIMO, mmWave, and Sub‑6GHz, ensuring SI, high/low‑temperature cycling, humidity, and vibration compliance.

Starting with DFM/DFT and SI/PI simulations, we combine high‑speed laminates, low‑loss processes, tight impedance control, and optimized shielding/thermal structures for stable 5G high‑frequency/high‑speed performance. Quality gates include automated assembly, X‑Ray/AOI/SPI, RF anechoic and OTA validation, plus burn‑in and lifetime testing. We support CTO, flexible lines, and traceable MES for short cycles and high‑mix/low‑volume needs. Through supply‑chain collaboration and global logistics, we shorten TTM, reduce BOM and manufacturing costs, and pursue zero‑defect on‑time delivery.

Communication Parts Mastars Serves

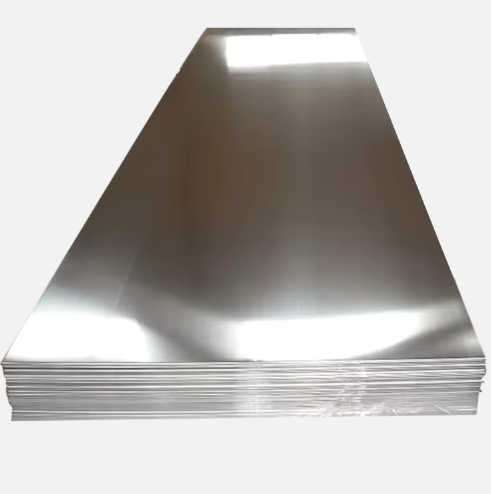

Materials for Communication Applications

Aluminum: ·2014 ·2024-T35 ·5052 ·6060 ·6063 ·7050

Copper: ·C101 ·C110

Stainless Steel: ·15-5 ·17-4 PH ·304/304L ·316/316L ·440C

Titanium: ·Grade 1 ·Grade 2 ·Grade 5

Top Precision Communication Applications

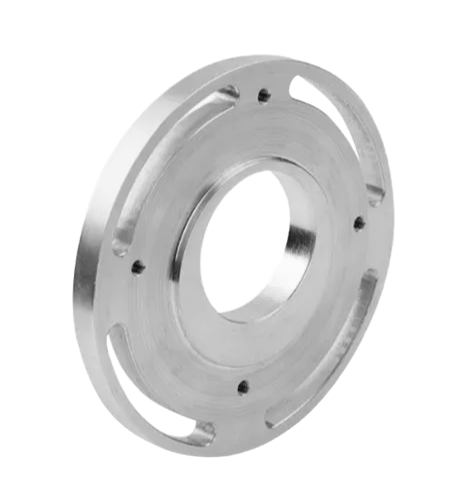

✔️ RF/EMI shielding and antenna structures:

RF shielding enclosures ●Telecom antenna brackets & mounts ●Small cell tower enclosures ●Naval radio antenna mounts ●Communication satellite brackets ●Radar system waveguides

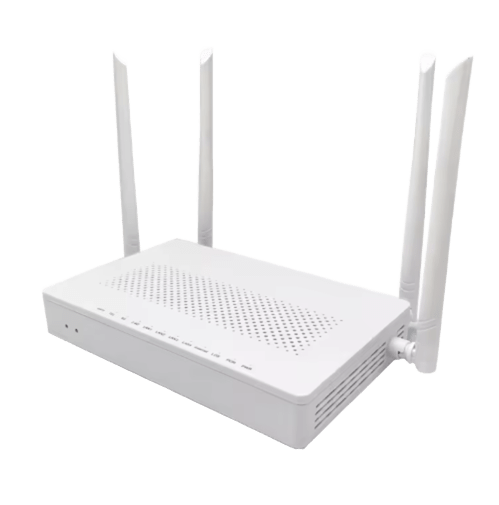

✔️ IT/network hardware enclosures and racks

Network rack and chassis components ●Server chassis & enclosures ●High‑speed router and switch casings ●Remote radio unit (RRU) casings ●Radio transmitter enclosures ●Encrypted radio device housings ●Wireless signal booster enclosures

✔️ Thermal management and audio/RF device housings

Heat sinks for network servers ●Cooling system heat exchangers ●Low‑noise amplifier (LNA) housings ●Amplifier casings ●Microphone body casings

Why Choose Mastars

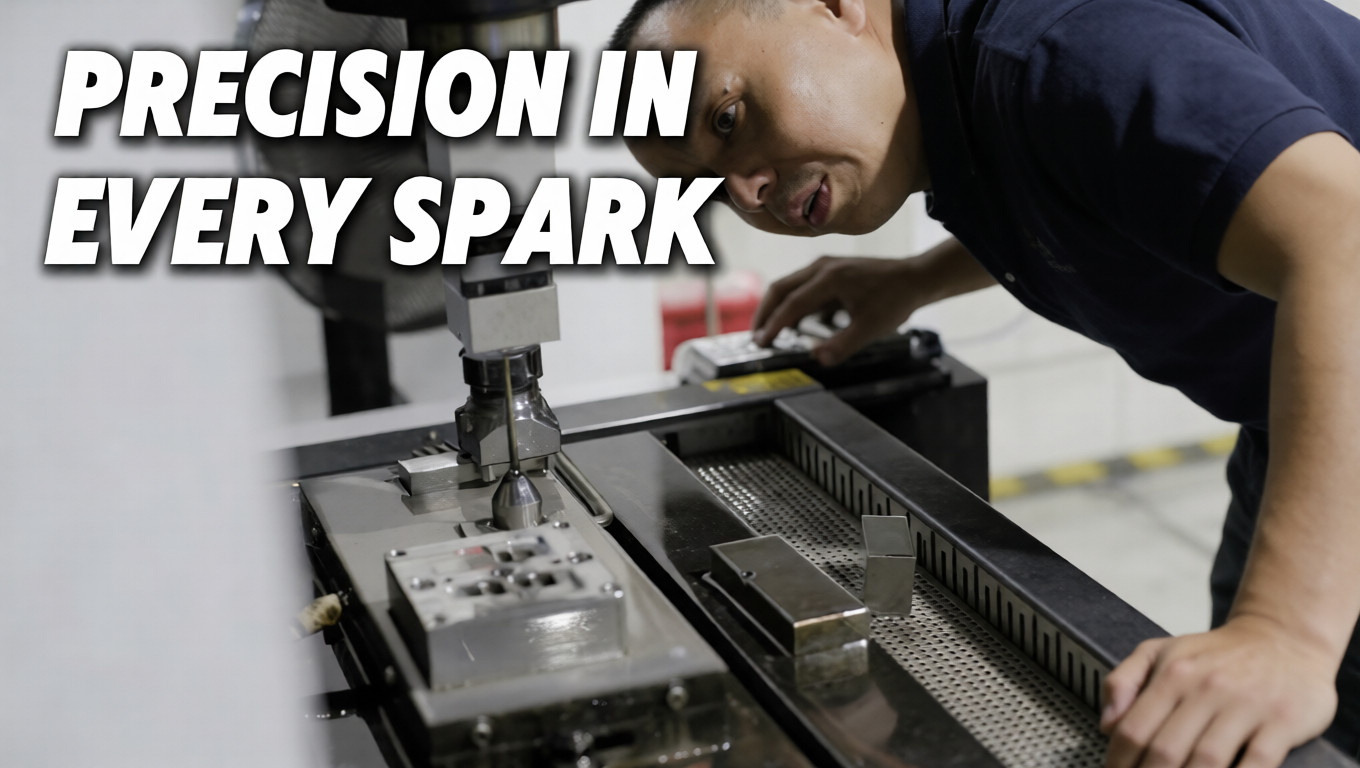

✔️Strong Manufacturing Capabilities

With ISO IATF certification, Mastars delivers communication parts that meet exact dimensions, structural integrity, and performance standards.

✔️Get Instant Quotation

Upload CAD to receive instant communication part quotes and start production immediately. Take control with real‑time order tracking and management.

✔️ Tight Tolerance Communication Parts

Tight‑tolerance CNC to ±0.001 in; supports complex custom parts.

✔️ Fast Cycle Time

Mastars delivers quotes in minutes and parts in days, cutting cycle times by up to 50%; our advanced technologies and extensive technical experience ensure high‑quality communication aerospace parts with faster lead times.

Robotics Post-Processing Capabilities

✔️ Anodizing

✔️ Passivization

✔️ Electroplating

✔️ Powder Coating

✔️ Insert Installation

✔️ Heat Treatment

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.