Background

Automotive programs run in safety-critical, multi-tier supply chains where a single defect can trigger recalls and liability. IATF 16949 harmonizes global automotive requirements on top of ISO 9001 to prevent defects, reduce variation, and ensure traceability. It mandates risk-based planning, documented control plans and Failure Mode and Effects Analysis, supplier oversight, Production Part Approval Process evidence, and disciplined change control—giving buyers audited, data-backed processes from request for quotation to serial production.

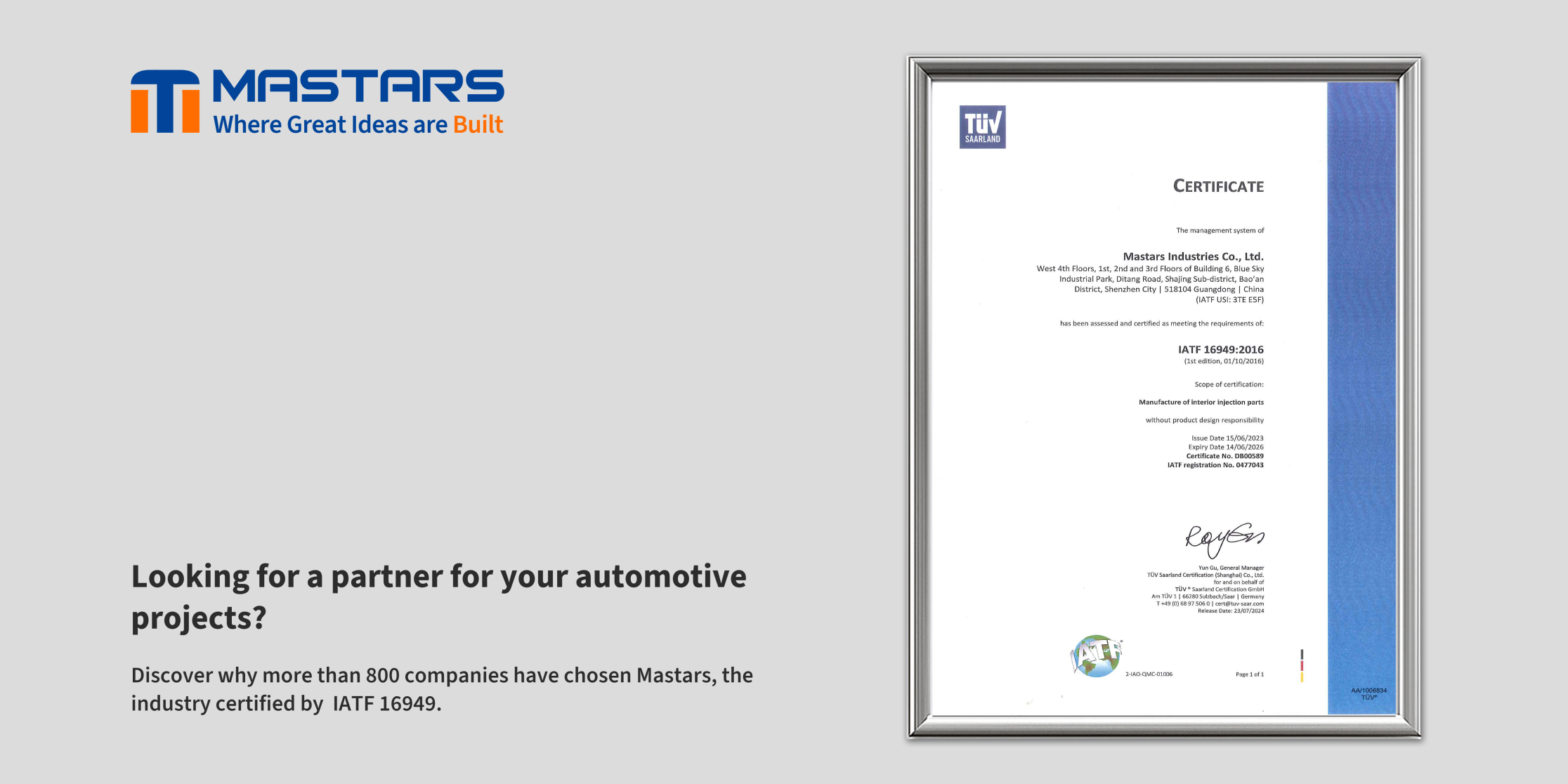

Certification

How Mastars Meets IATF 16949 Requirements

- Map end-to-end processes and set measurable quality objectives with regular management review.

- Run Advanced Product Quality Planning and Production Part Approval with complete, consistent documentation.

- Link drawings, tooling, and inspection through control plans and Failure Mode and Effects Analysis.

- Apply Statistical Process Control and Measurement System Analysis to critical characteristics; calibrate and record gauges.

- Qualify and monitor suppliers; enforce incoming identification and lot-to-material traceability, supported by a ZEISS CONTURA CMM lab.

- Control nonconformities and corrective actions to verified effectiveness; maintain document control, training, layered audits, and shop-floor change management.

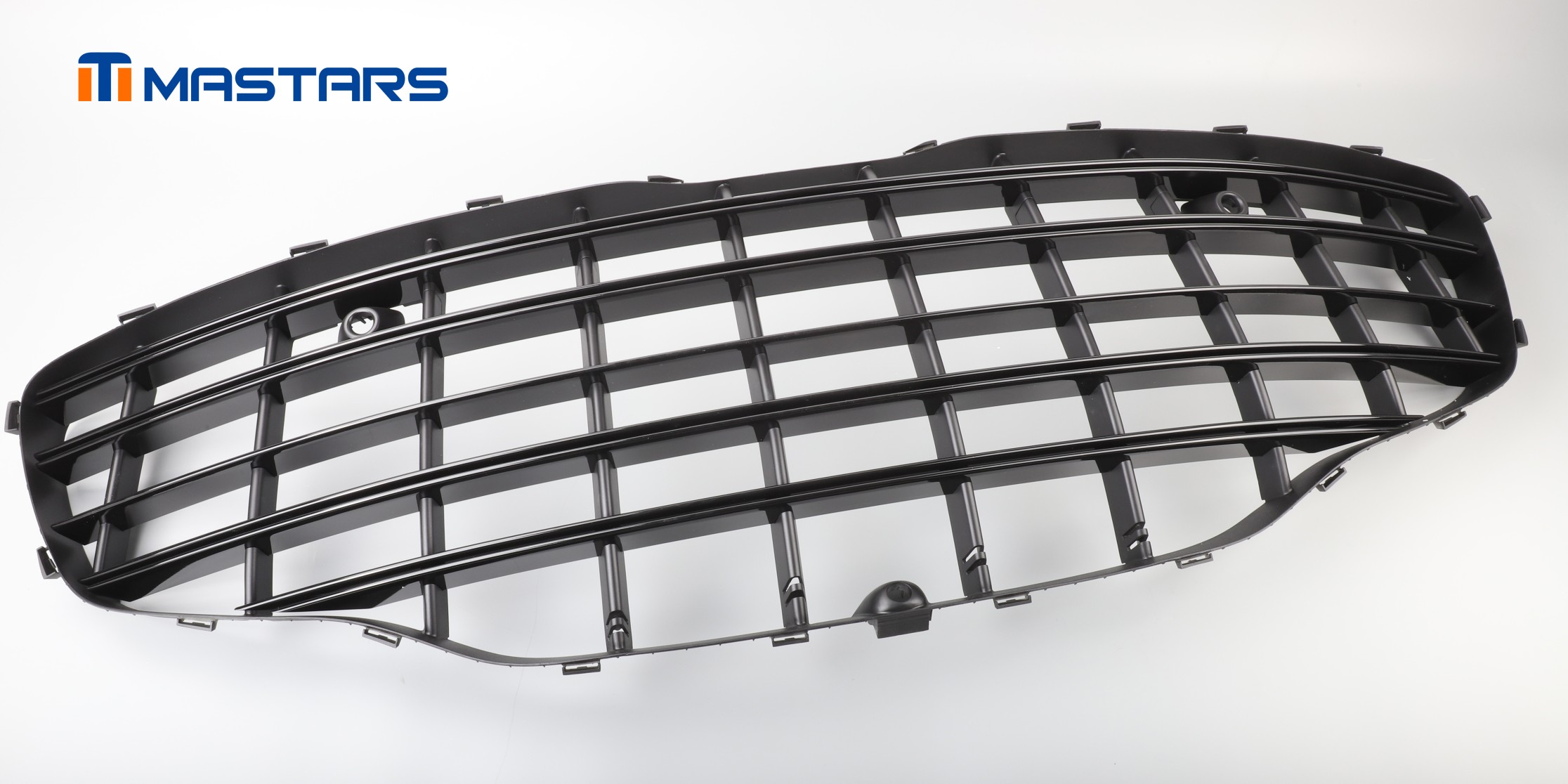

Injection-molded car front grille

You get faster approvals and predictable quality

✅ Lower launch risk with audit-ready evidence from prototype to mass production.

✅ Faster customer approvals because PPAP packages are consistent and traceable.

✅ Stable dimensions and cosmetics across shifts, tools, and batches.

✅ One accountable partner operating to a single certified system.

✅ Stronger compliance embedded in daily operations and verified by data.

Die-cast and CNC-machined transmission housing

We build from prototype to turnkey assembly

- Prototyping: CNC machining, vacuum casting, 3D printing, sheet-metal fabrication.

- Tooling & plastic parts: plastic tooling, injection molding, plastic extrusion, silicone compression molding.

- Metal parts: pressure die casting, CNC machining, metal injection molding (MIM), metal extrusion.

- OEM & ODM delivery: joint R&D, project management, new-product introduction, full turnkey assembly.

Vacuum casting automotive intake duct

In short: certified certainty

You get a partner that designs quality into every operation, proves it with documented controls, and scales from prototypes to serial production without changing the rulebook. That is how Mastars turns timelines into commitments and risk into confidence.

Large automotive stamping press

——————————————————————————————————————————————————————————————————————————————————————————————————————

Mastars, the world's most trusted one-stop small and medium-volume digital manufacturing service provider.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.