Applications and Key Design Questions

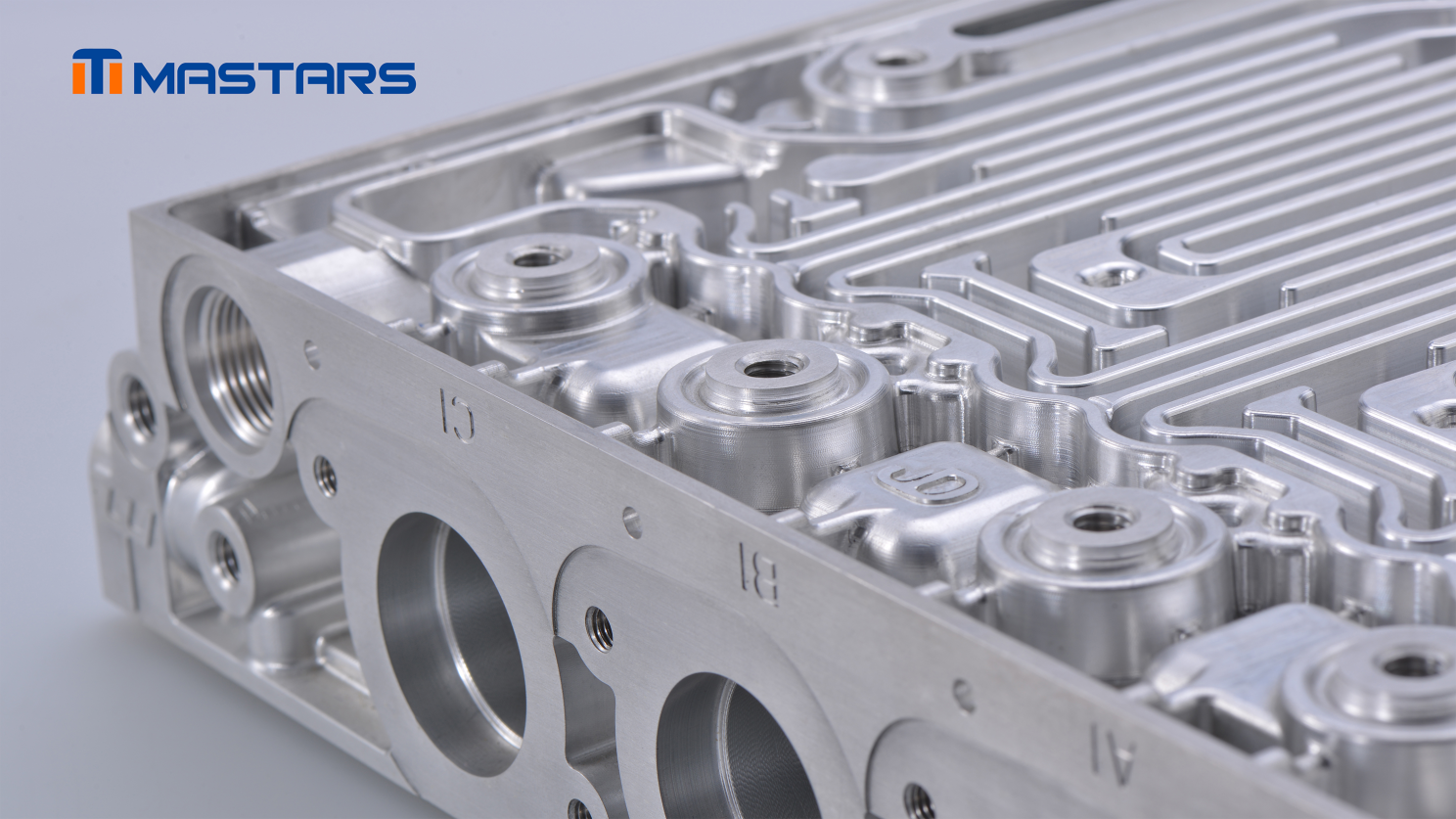

In this particular project, an AI server company from the United States entrusted Mastars to manufacture a bespoke liquid cooling plate for its advanced computing systems. These projects demand multiple requirements at once. The machined cavities must align perfectly to mate with other housings and gaskets. Thermal management drives the layout of labyrinthine channels, while sealing features around ports and fasteners ensure leak‑free operation. Cleanliness and dimensional repeatability are also vital so that assembly and inspection are consistent across batches.

Does your team struggle to balance cooling efficiency with tight geometric control? Check our solution: this cold plate is filled with winding channels, cavities, and threaded ports. Such plates are common in high‑power electronics and battery modules where liquid cooling is essential. Fluid must traverse uniformly through complex machined paths to extract heat from sensitive components without introducing leaks or turbulence.

Detials of a presicion-machined aluminum liquid cooling plate, featuring serpentine flow channels and threded ports.

Manufacturing Approach and Quality Controls

The hardest task here is machining deep, interlaced channels and thin walls without distortion or tool chatter. Handling such complexity requires advanced multi‑axis milling strategies and fixtures that minimise vibration and maintain parallelism. Mastars’ engineers provide early design‑for‑manufacturability feedback to adapt channel geometry, corner radii and wall thicknesses for smoother tool paths. This reduces machining time and lowers scrap risk.

Our process route begins with billet preparation and rigid fixturing. Continuous 5‑axis milling removes bulk material, then finishes the narrow channels using small‑diameter end mills. After machining, precision deburring and surface conditioning create smooth flow paths and mating surfaces. Throughout production, we monitor critical features with coordinate‑measuring machines and leak‑testing fixtures, and we document each step for traceability.

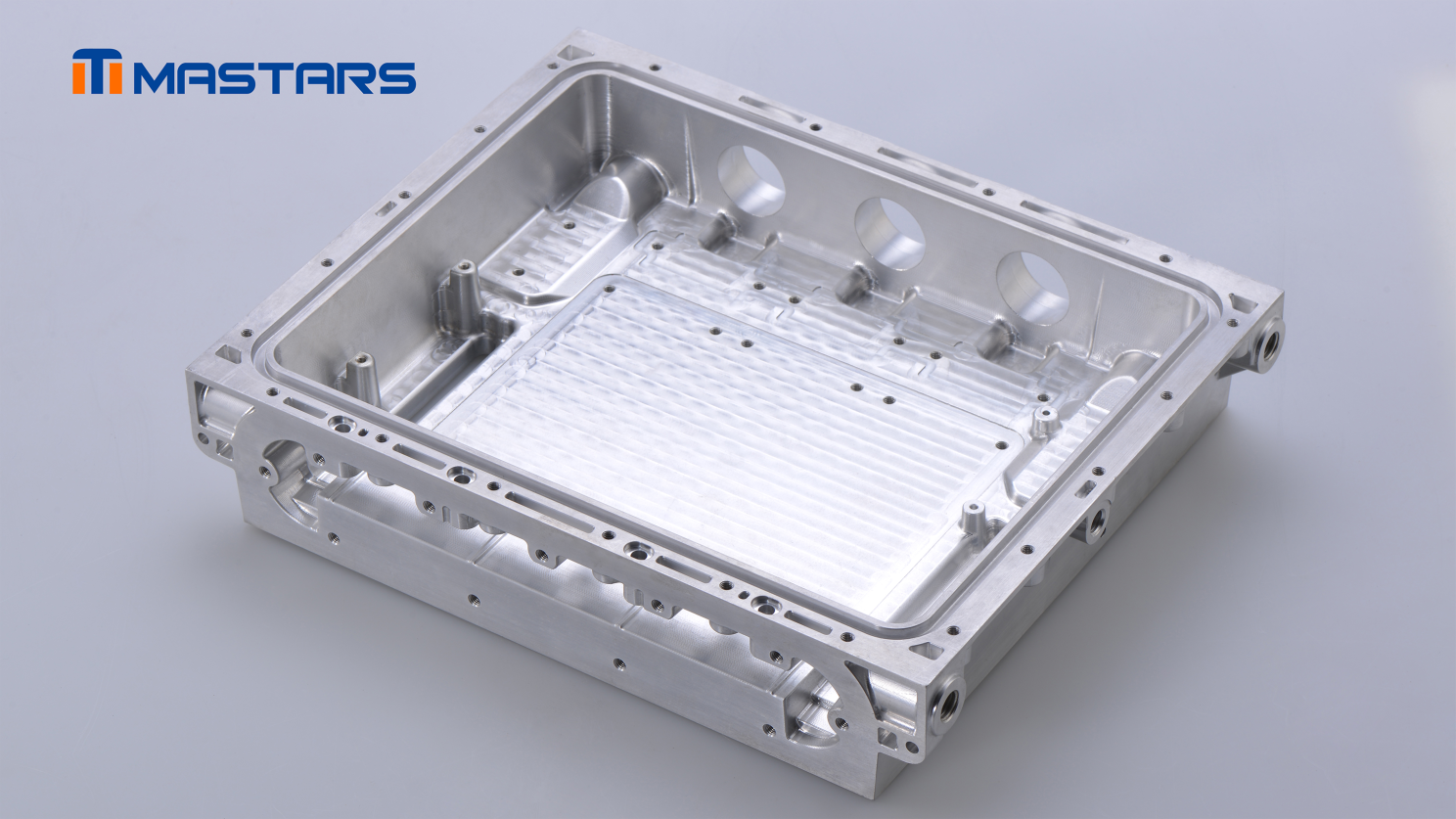

Interior cavity and mountng-hole layout of a precicion-machined aluminum housing.

Value Delivered to Your Project

Client core value: Mastars delivers stable thermal performance and assembly consistency.

✅ Reliable liquid flow through smoothly machined channels and ports

✅ Precise flatness and hole position for leak‑free gasket sealing

✅ Repeatable dimensions to simplify downstream assembly processes

✅ Clean surfaces that prevent contamination of sensitive electronics

✅ Traceable build records to support quality audits and validation

Interior cavity and mounting-hole layout of a precision-machined aluminum housing.

Cross Industry Insights

Complex cooling housings are not unique to one sector. Engineers across industries face similar challenges when intricate cavities, tight tolerances, and thermal management intersect.

- Automotive — battery coolant plates

- Aerospace — avionics thermal plates

- Medical devices — imaging equipment casings

- Industrial machinery — power inverter housings

What demands do your cooling or housing projects present? Do you have difficult 3 to 5-axis parts that most manufacturers cannot make? Tell us about your project and see how Mastars’ integrated machining and quality control can help.

Mastars, the most trusted and reliable one‑stop services partner for low‑volume digital manufacturing worldwide!

Hot Articles

Prototyping Lockwaste Smart Bin Lock for Australia with 3D Printing, Vacuum Casting, and a Matte Finish

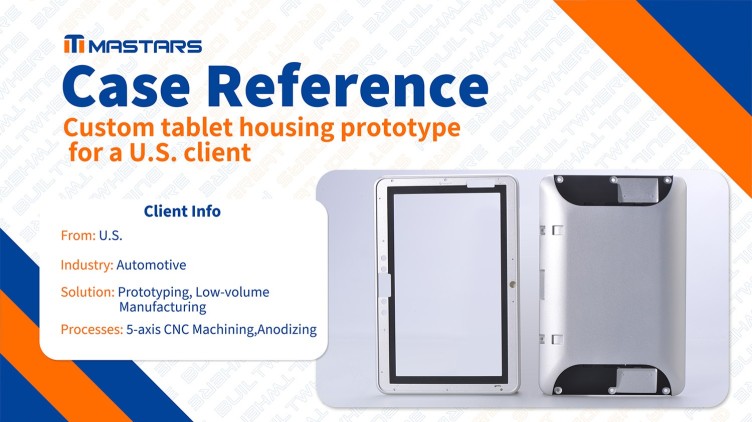

Custom tablet housing prototype for a U.S. client: one-piece 5-axis CNC precision machining, strict detail control, anodizing finish

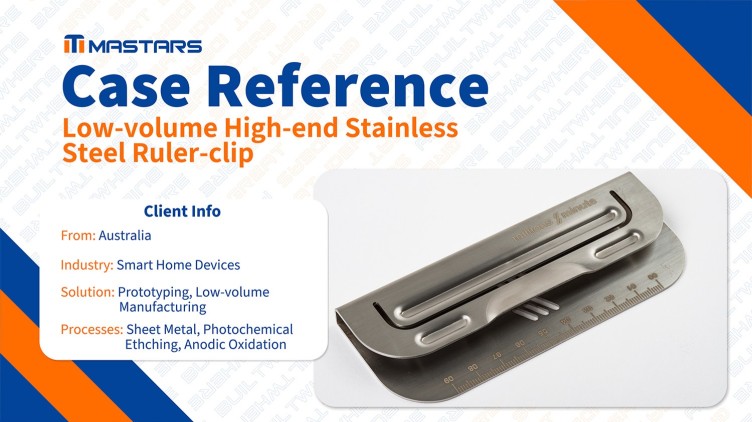

Mastars’ Low-volume Manufacturing Services Deliver a Premium Stainless Steel Ruler-Clip

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.