Background

Electric surfboard/e-foil brands require motor housings that are light and rigid, present clean hydrodynamic exteriors, maintain leak integrity with O-rings and threaded end-caps, offer premium uniform cosmetics for consumer markets, and scale from pilot to steady production with consistent dimensions across batches.

E-foil board surfing on sea water

The Challenge

A marine motor pod must balance stiffness, low mass, and serviceability while holding accurate bores/threads and sealed interfaces. Single-process parts struggle with thin-wall control, true-positioned holes, and cosmetic uniformity under saltwater exposure.

Mastars Solution

Mastars executed the entire build under one roof—tooling, casting, machining, finishing, and inspection—so datum schemes, machining allowances, and surface cosmetics stayed aligned end-to-end.

Process chain:

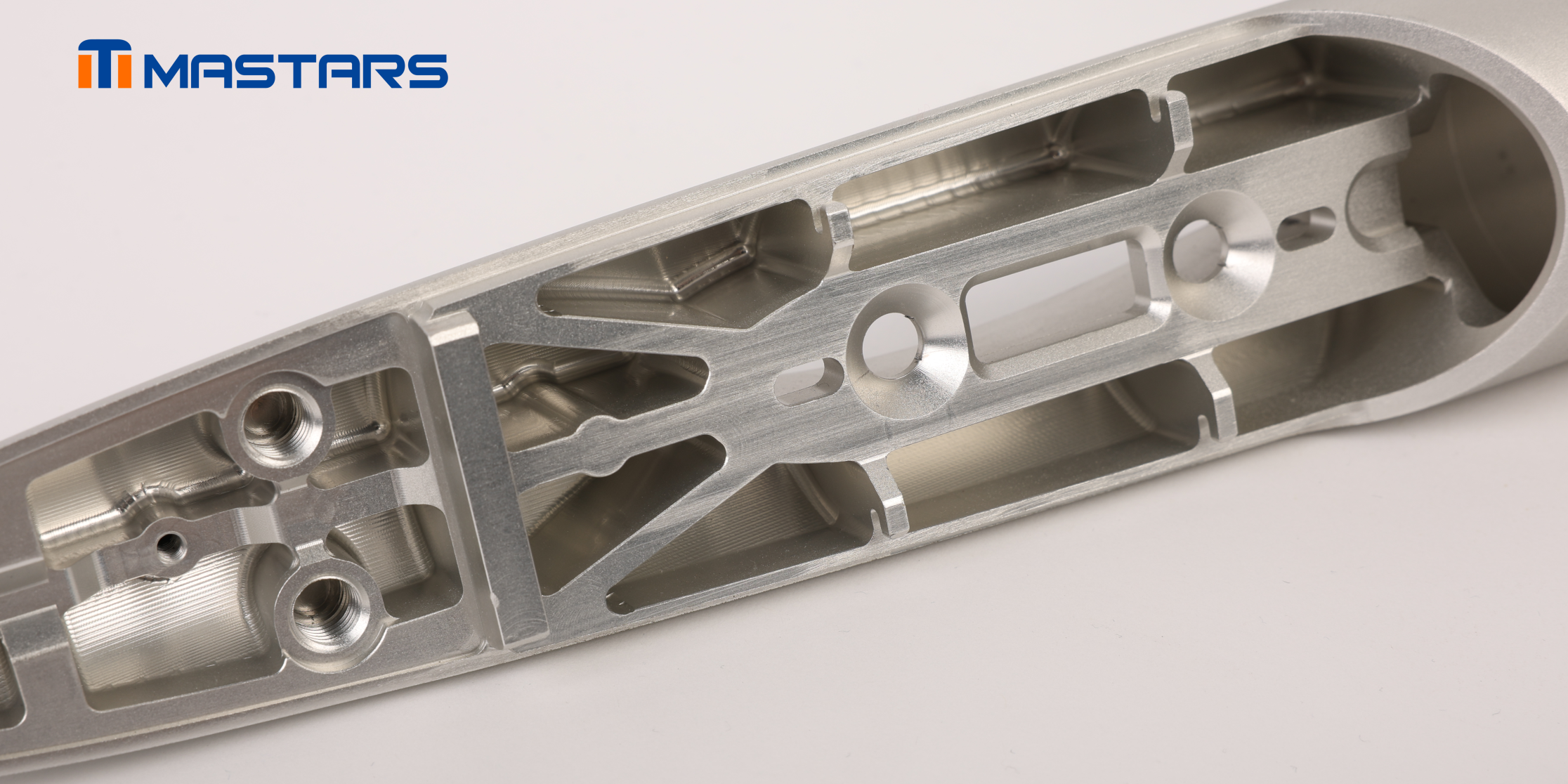

- Die casting (Al alloy): Near-net shell with integrated ribs, pockets, bosses, and a recessed branding area. Gates/vents are trimmed and reference datums established.

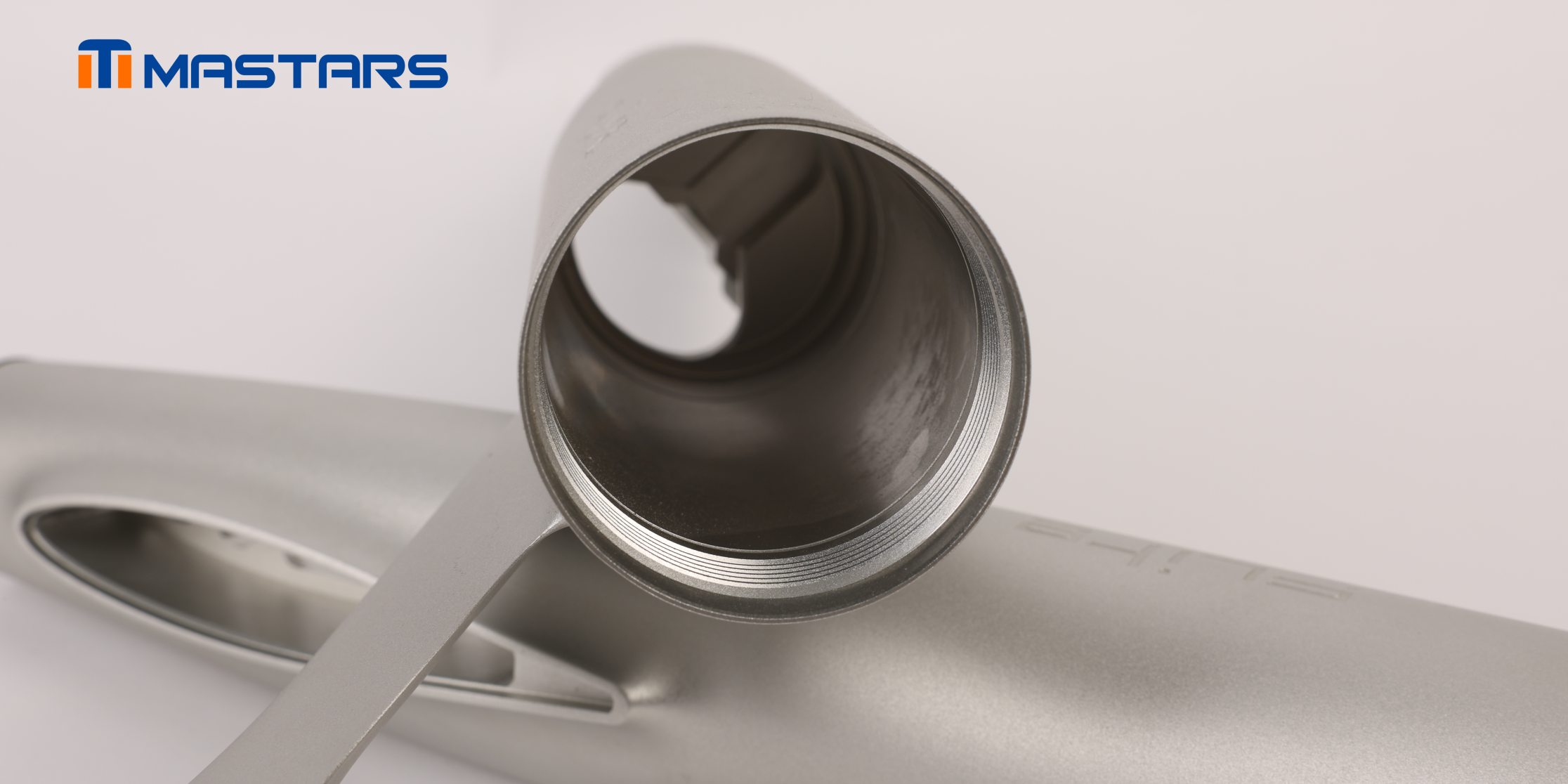

- 5-axis CNC finish: Critical features are brought to spec—internal pockets cleaned, mounting holes drilled/tapped, and the end-cap bore with internal thread precision-cut. Deburr and edge breaks ensure safe assembly.

- Bead-blast + anodize: Uniform matte texture achieved by bead blasting, followed by clear anodizing for corrosion resistance and consistent appearance.

Low mas design

System Features

- Die-cast structure: Thin-wall ribs and pockets reduce mass while maintaining stiffness; cast-in bosses localize load paths.

- Machined interfaces: True-positioned hole set, flat seating lands, and threaded end-cap interface enable repeatable assembly; long internal cavities are reached with coordinated 5-axis toolpaths.

- Cosmetics & durability: Even matte finish after blasting; clear anodized exterior suited for saltwater environments.

- Branding readiness: Recessed exterior branding area kept crisp through controlled media and masking.

- One-stop control: Casting parameters, CNC programs, finishing specs, and inspection plans are integrated at Mastars for batch-to-batch consistency.

Benefits

✅ Weight with stiffness: Die-cast ribs plus selective CNC deliver low mass without sacrificing rigidity.

✅ Assembly confidence: Precision-cut threads and hole patterns align with the end-cap for smooth serviceability.

✅ Consistent look: Integrated blasting and anodizing provide uniform texture and color across parts.

✅ Production-ready: The same process chain scales from prototypes to volume with shared fixtures and travelers.

Thin-wall

Thin-wall

Use Cases

Electric surfboards and e-foils: motor pods, end-cap modules, sealed ESC/electronics cans, thruster shells.

Beyond e-surf:

- Automotive & EV: coolant pump housings, actuator pods, compact gearbox covers.

- Medical: peristaltic/centrifugal pump housings, fluid-path manifolds, sealed instrument enclosures.

- Industrial & lab equipment: small pump bodies, valve/manifold blocks, fluid-path enclosures.

- Aerospace & UAV: gimbal/actuator motor pods, lightweight sealed electronics housings.

——————————————————————————————————————————————————————————————————————————————————————————————————————————————

Mastars, the world's most trusted one-stop small and medium-volume digital manufacturing service provider.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.