Background

Prototype or small-batch injection parts must prove the design early—geometry, draft, ejection, assembly fit, and cosmetics. Waiting for a full metal mold to learn these lessons is slow and expensive. A faster surrogate mold helps you validate before committing capital.

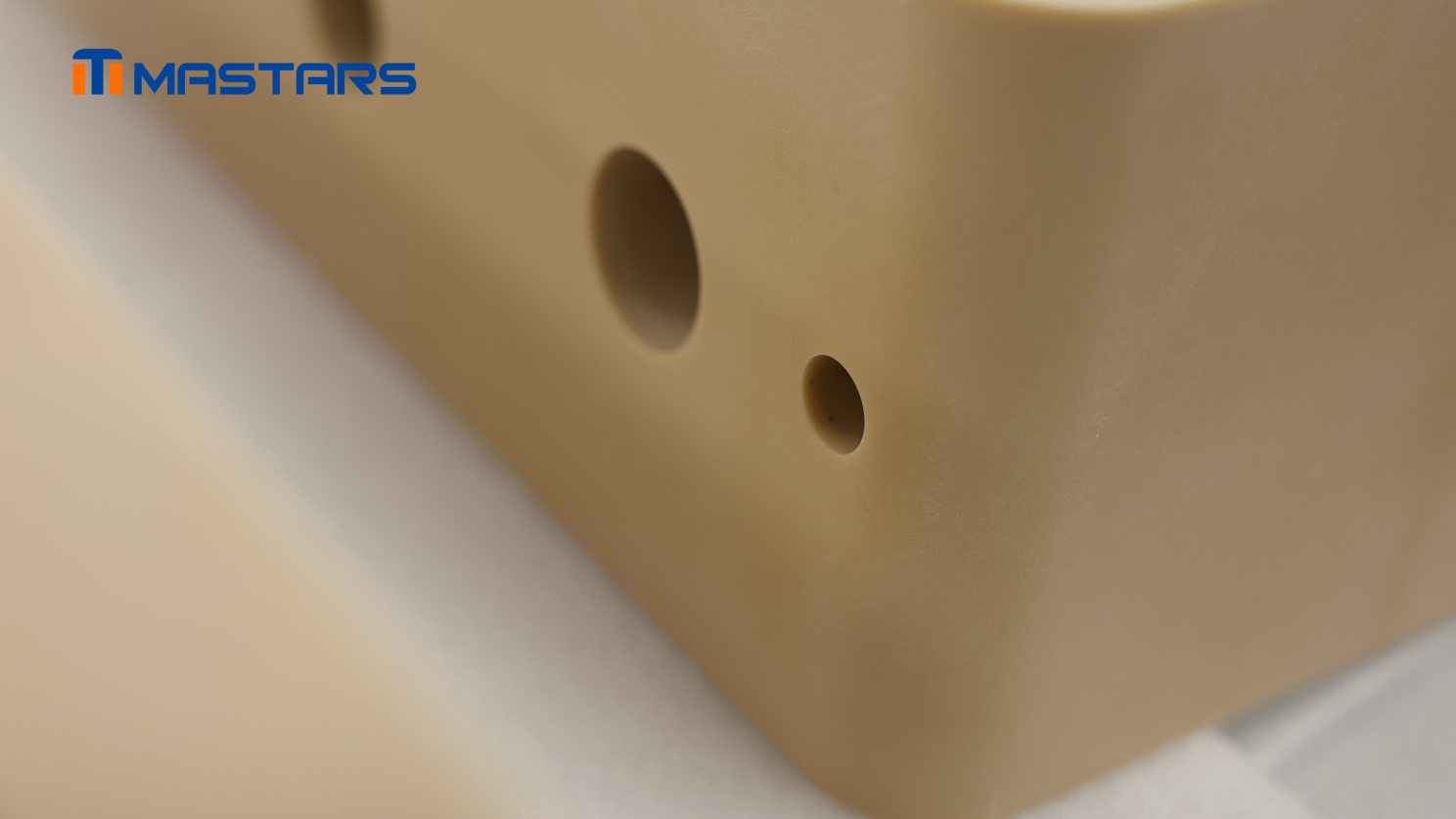

PU mold is easy to be CNC or hand-made

The Challenge

Metal molds are costly, and lead times are long. Each iteration multiplies programming, steel, and try-out costs. For many checks, you do not need steel’s service life—you need a quick, accurate, low-risk way to mill cavities and test ideas.

Mastars Solution

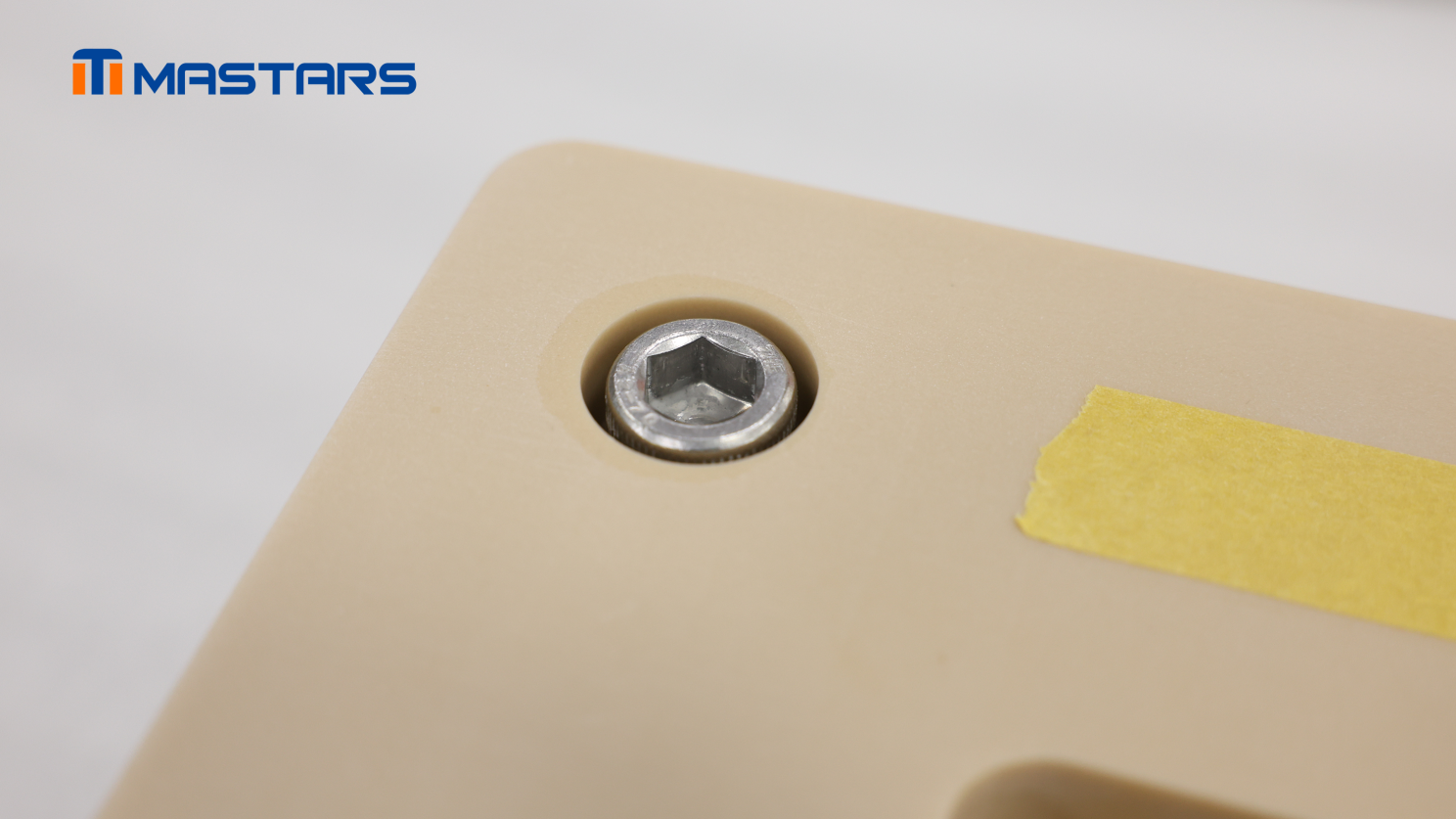

Mastars recommends PU (polyurethane) tooling board for surrogate mold inserts, masters, and fixtures. We mill by CNC in hours, then seal and finish the surface for clean demolding. Use it to verify parting/draft, sliders & ejectors layout, gate/runner geometry, and assembly fit. Run low-temperature, low-pressure trials, capture data, and lock the design before cutting metal.

Tooling board validates design before manufactruing the metal mold

Benefits

One fast surrogate mold to de-risk the real one.

✅ Fast machining & iteration: cut in hours; easy to re-cut.

✅ Clean, paintable surface: dense, easy to seal; low dust when milled.

✅ Dimensional stability: good compressive/edge stability for gauges & masters.

✅ Usable temperature: typical HDT (heat deflection temperature) ~70–90 °C—ideal for low-temp trials.

✅ Lower cost: a fraction of steel/aluminum; avoids costly rework on the final tool.

The slick and smooth surface of the PU tooling board made it suitable for plastic injection molding

Use Cases

The tooling board is mostly for prototypes; these industries often validate before cutting metal:

- Consumer electronics & appliances: enclosures, snaps, fit gauges; typical resins for trials

- Automotive interior & trim: bezels, ducts, sealing studies

- Medical (non-implant) & lab devices: housings, fixtures; materials: ABS/PC, PMMA, plus silicone/PU casting for prototypes.

Mastars——world's most trusted one-stop small and medium-volume digital manufacturing service provider.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.