Background

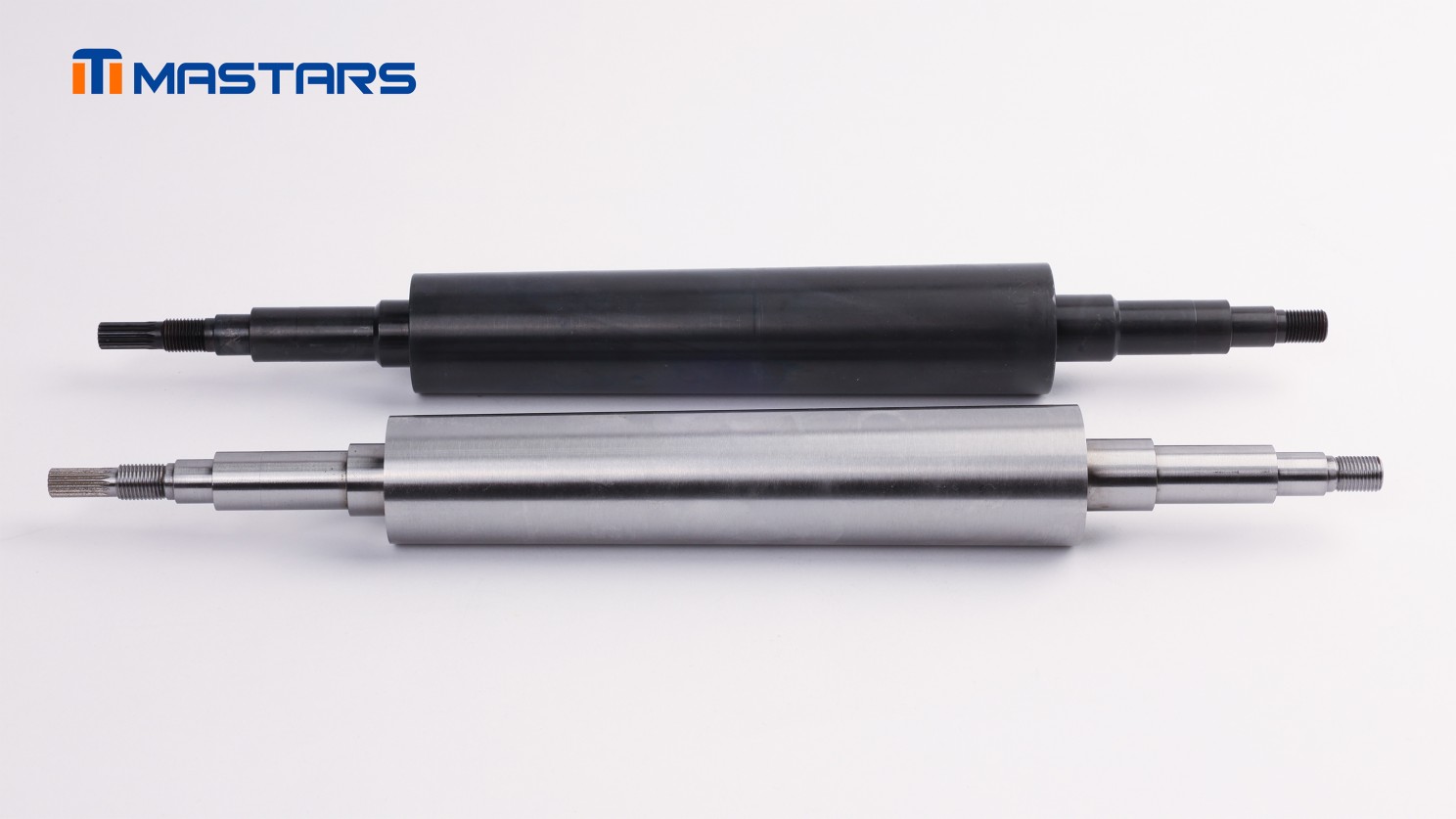

During prototype or small-batch production, aerospace components require functional validation before large-scale manufacturing. Rotational shafts, which transfer motion and torque in engines or actuation systems, must demonstrate both dimensional accuracy and surface integrity at this stage.

The Challenge

Aerospace-grade shafts often involve complex geometries, tight tolerances, and critical surface finishes. Using standard off-the-shelf tools or molds is not sufficient. Custom tooling and controlled machining are essential—but they also increase setup time and manufacturing cost.

Mastars Solution

At Mastars, precision starts from the prototype stage. We combine our rapid prototyping capability with advanced CNC machining to ensure every aerospace shaft design is validated before production.

Leveraging our in-house machining center, engineers can quickly simulate real machining conditions and validate part performance, optimize geometry, and confirm functional performance quickly. Once validated, the same data seamlessly transitions into small-batch or production machining.

We design and produce custom cutting tools specifically optimized for each shaft geometry. Through a combination of high-speed turning, precision grinding, and process control, we achieve consistent surface quality and micron-level accuracy—while keeping development lead time short.

Benefits

A high-precision, repeatable, and efficient process for aerospace-grade metal components.

✅ Achieves surface roughness Ra ≤ 0.2 μm through precision grinding

✅ Tight dimensional control for complex geometries

✅ Seamless transition from prototype to production

✅ Shorter lead time with in-house tool design and CNC programming

✅ Reliable consistency through process monitoring and traceability

Use Cases

Ideal for precision component validation across:

- Aerospace and defense systems

- Automotive and electric mobility

Industrial automation and robotics

Mastars — world’s most trusted one-stop small and medium-volume digital manufacturing service provider.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.