Background

Prototyping is a critical step in manufacturing. It proves form, fit, and function before you invest in tooling. In automotive, consumer electronics, medical devices, and other industries, fast prototypes align design within different teams, expose risks early, and keep programs on schedule.

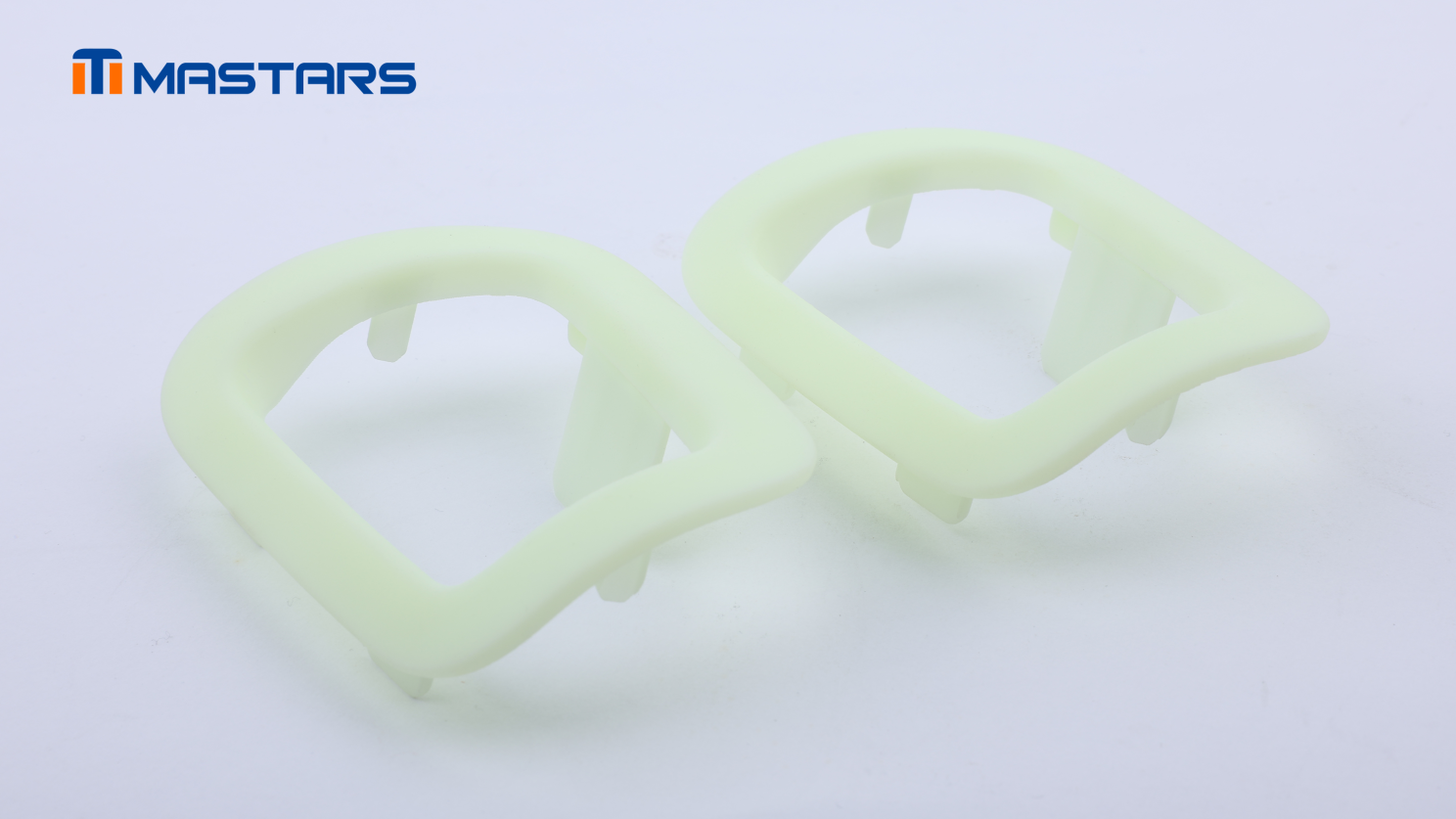

SLA with ABS for cheap and rapid prototyping

The Challenge

CNC prototypes can be slow and expensive: setups, fixtures, and toolpaths add cost; changes force re-machining and scrap. Complex internal channels or undercuts may be impractical. Long lead times slow decisions and push tooling later. Worse, some teams try to “save time” by skipping prototypes and cutting steel directly—locking design errors into hard tooling and triggering costly rework, tool damage, and missed launch windows. You need a quick, accurate, low-risk way to prove fit, sealing surfaces, and gating/ejection before committing to high-value molds.

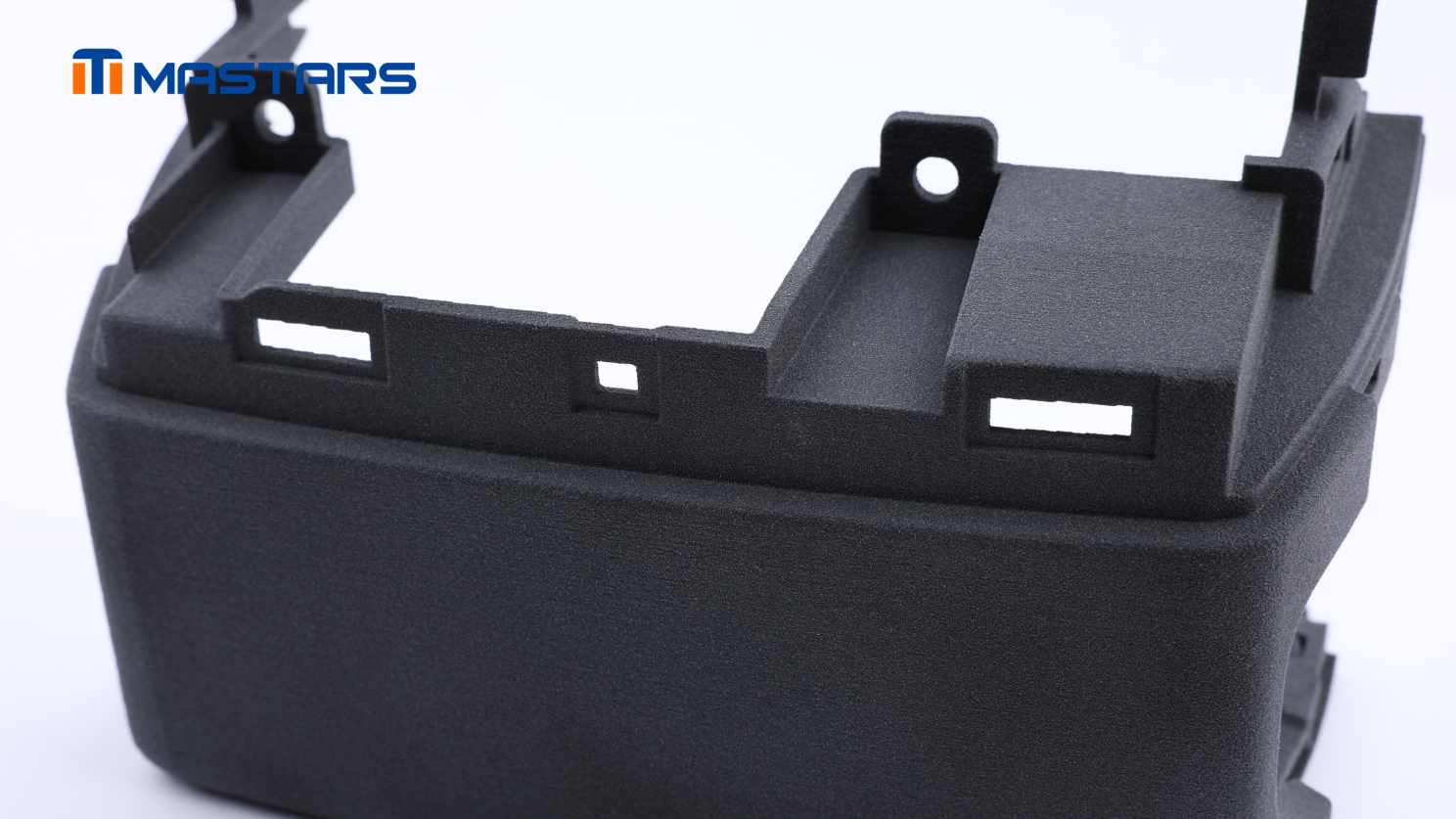

MJF with nylon makes the prototype functional

Mastars Solution

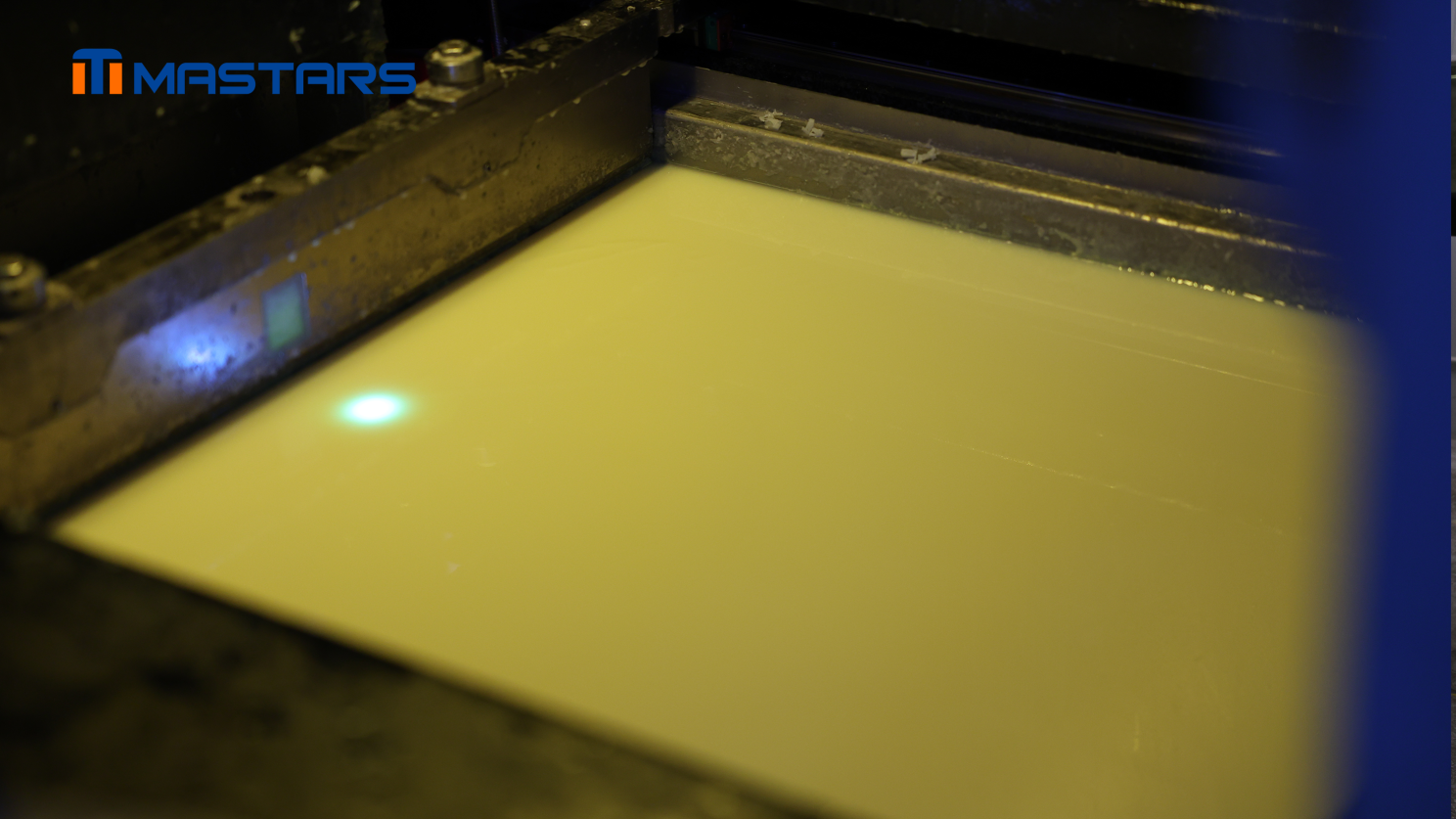

Mastars accelerates prototyping with industrial 3D printing: SLA (stereolithography) for smooth, watertight parts and clear optics; MJF (multi jet fusion) for tough, accurate nylon assemblies; SLM (selective laser melting) for metal prototypes and brackets. We add DFM review, finishing (sanding, tapping, inserts, coatings), and metrology. When designs freeze, we bridge to CNC, soft tooling, and production molds.

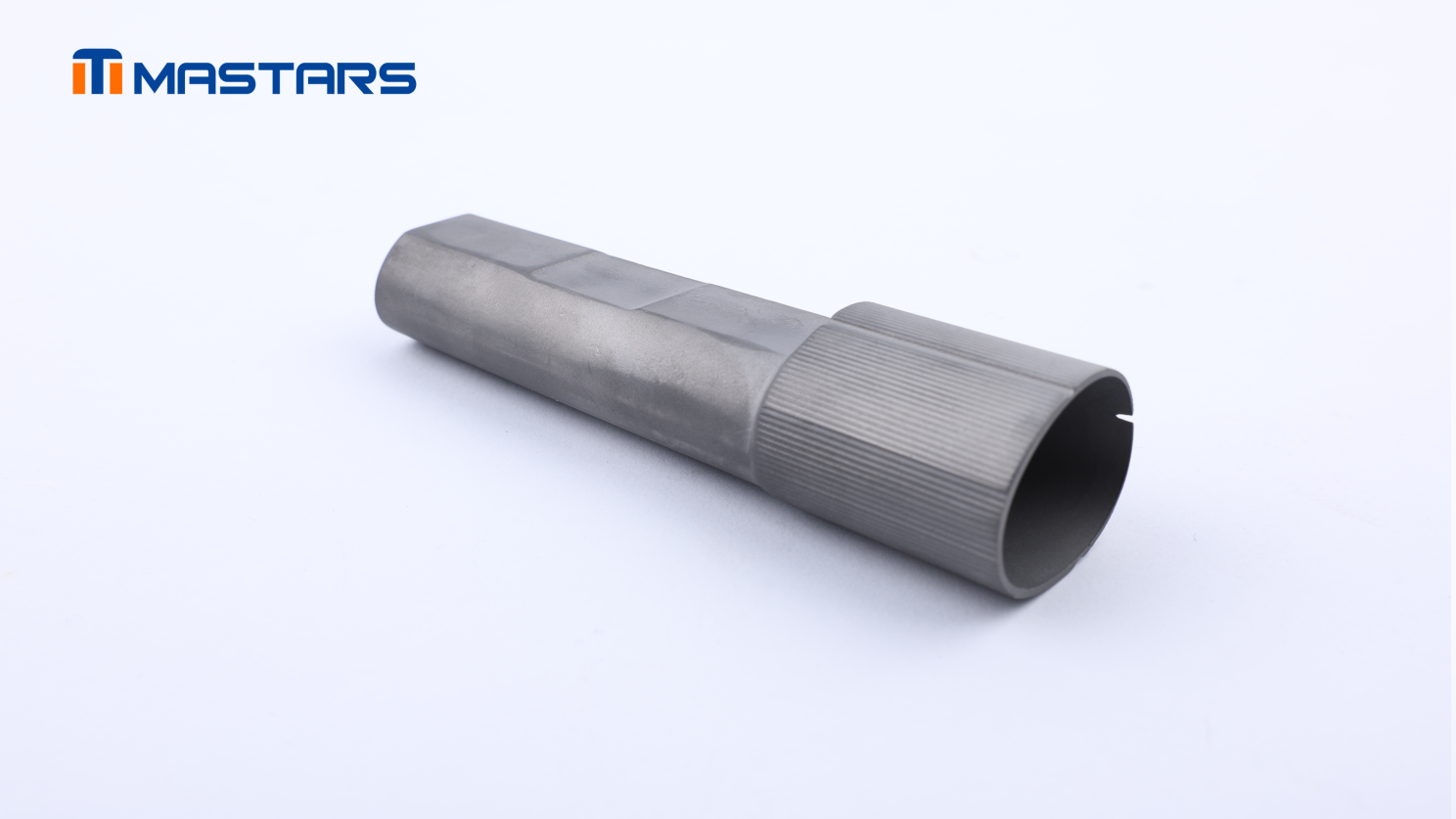

SLM using aluminum powder as material

Benefits

The right process at the right stage, with less risk.

✅ SLA advantages: very smooth surface, high detail, clear/opaque options; good for visual models, seals, and fluid paths.

✅ MJF advantages: strong, dimensionally stable nylon; accurate assemblies; durable clips and housings; batch-friendly.

✅ SLM advantages: functional metal parts with internal channels; high strength/heat resistance; threads and pressure-bearing features.

UV-cured with ABS fluid

Use Cases

How teams apply SLA/MJF/SLM before cutting tools.

- Automotive & mobility: ducts, brackets, housings, ergonomic bucks.

- Consumer electronics & appliances: enclosures, snaps, cosmetic masters.

- Medical (non-implant) & lab equipment: housings, fixtures, fluid manifolds.

- Industrial automation & robotics: end-effectors, jigs, sensor mounts.

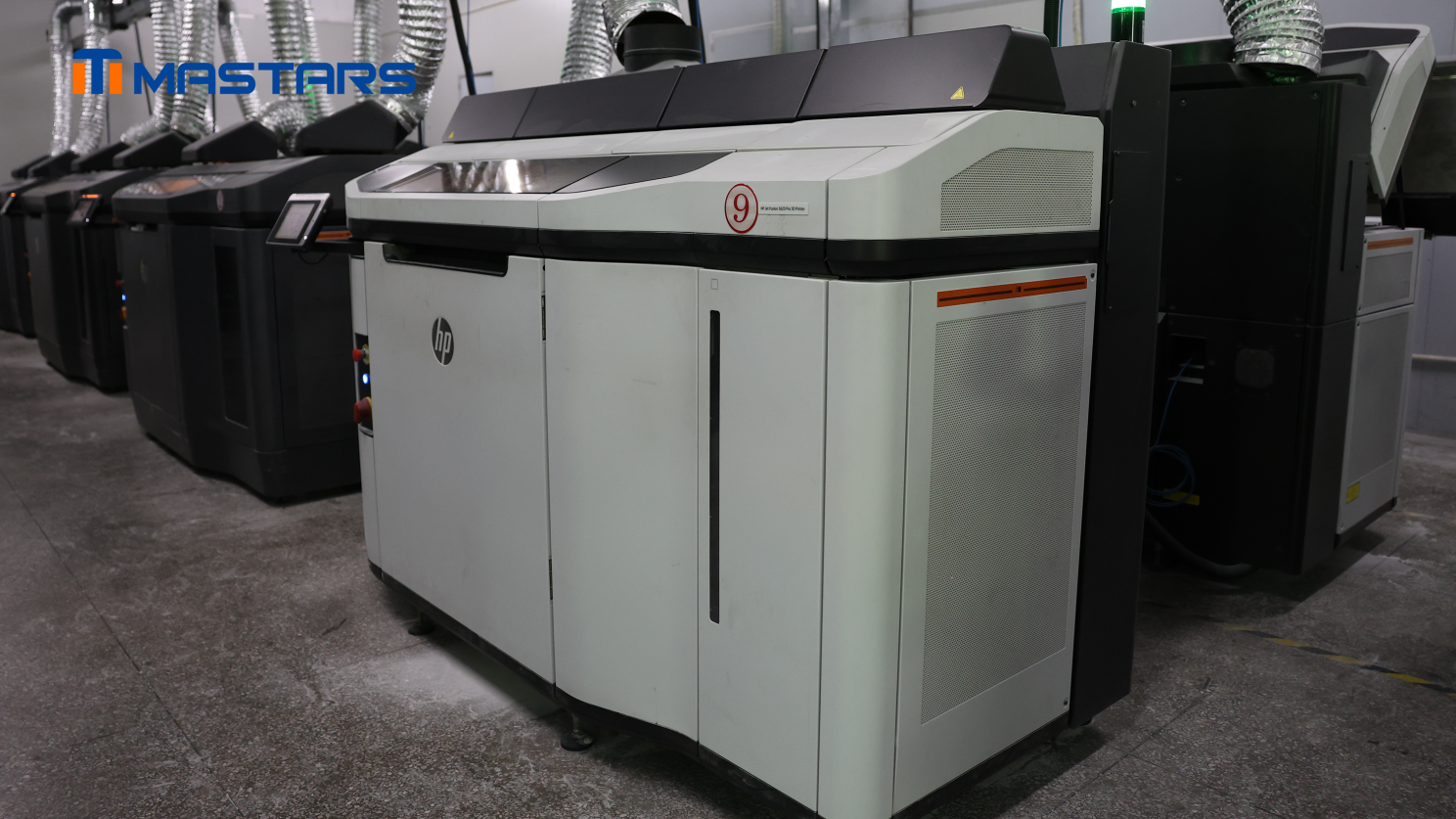

HP MJF printer

Mastars——world's most trusted one-stop small and medium-volume digital manufacturing service provider.

Mastars——world's most trusted one-stop small and medium-volume digital manufacturing service provider.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.