Background

A medical company from Australia requires large CT ring light display models for trade shows, showrooms, and customer demonstrations. These oversized parts must reproduce the final geometry, seam control, and paint quality, but without the cost and lead time of production tooling.

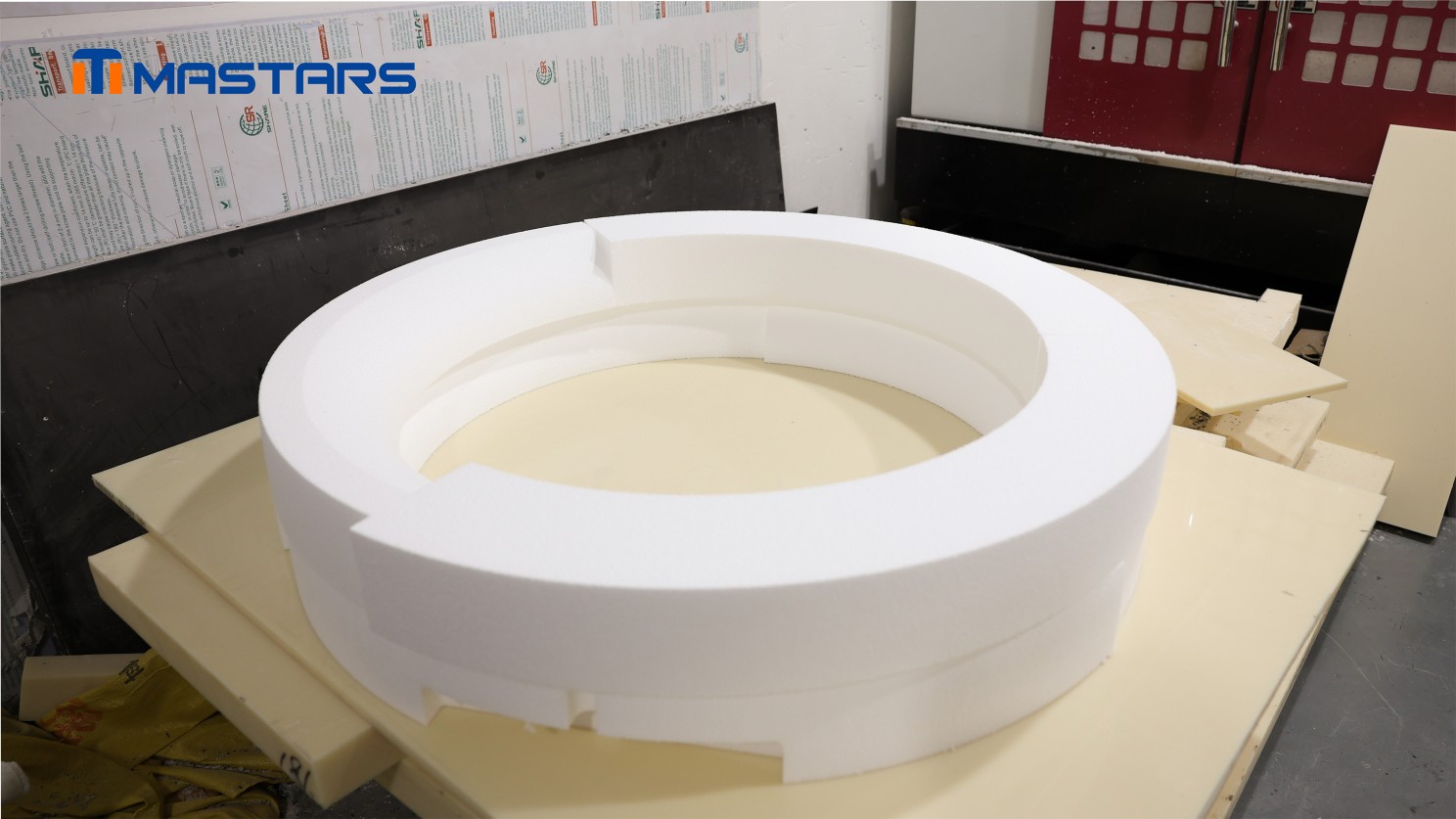

For this project, the structure combined 3D-printed ABS segments for the outer profile, PU/EPS foam blocks for lightweight internal volume, CNC rough machining to form the core, manual surface correction, and a multi-cycle painting process. A 5052 sheet-metal base was fabricated to provide alignment, stiffness, and safe handling.

Engineers review the CT ring light structure in CAD.

The Challenge

Large medical display rings create several risks: roundness can drift during bonding or transport; splice lines can show through paint; and foam surfaces can print through under lighting.

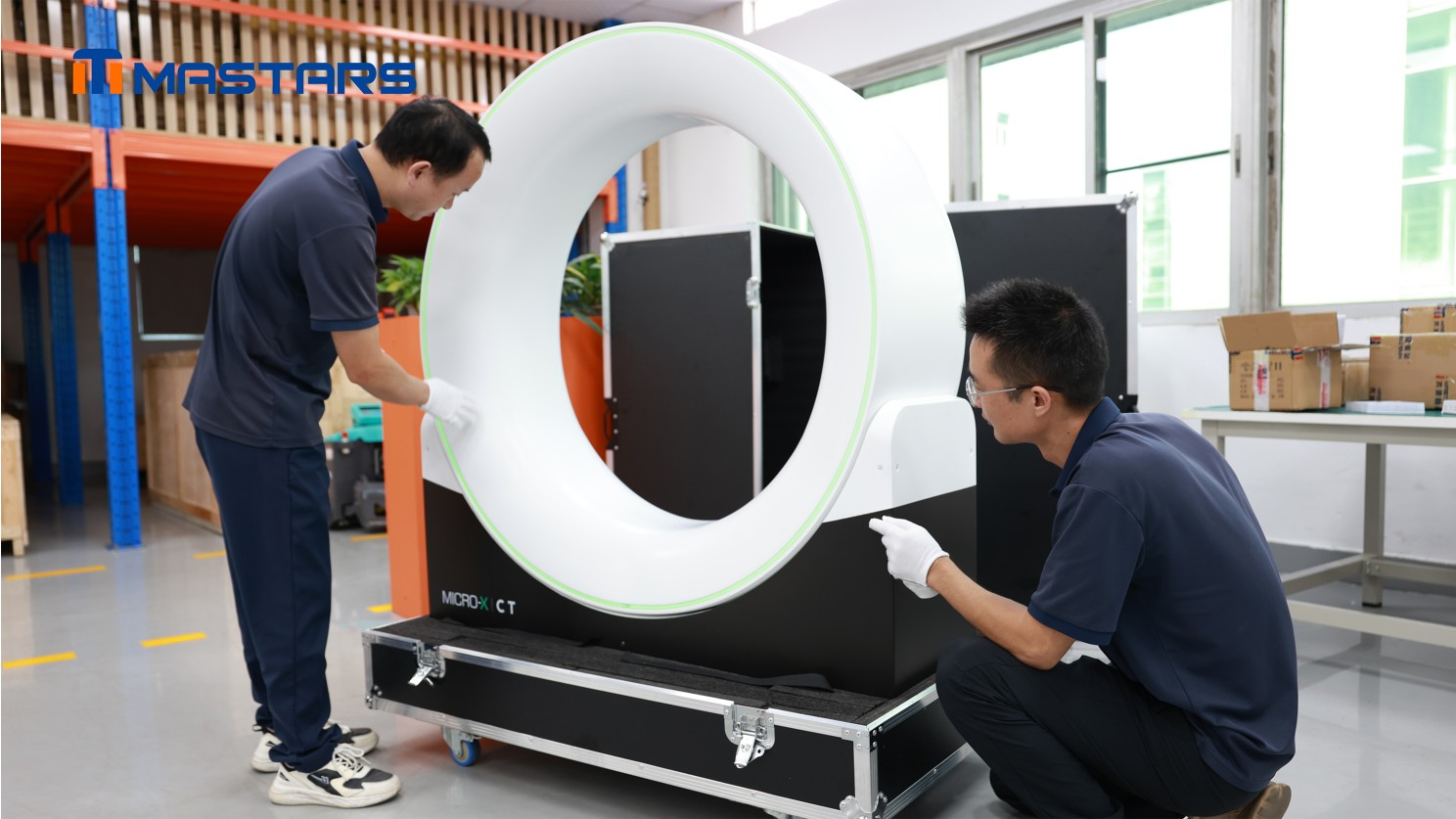

The customer also needed a model light enough for manual handling, but stiff enough to avoid deformation. Alignment between the ring and its base had to be held within tight limits, even though the project could not justify production-grade molds, fixtures or long machining cycles.

Mastars Solution

Mastars divided the ring into ABS shell segments to lock the final outer geometry. Inside, PU and EPS foam blocks were bonded and CNC-machined into a stable, lightweight form. Technicians then performed filled-joint correction, coaxiality checks, and progressive manual sanding. Painting followed a controlled three-step sequence: primer sealing, mid-coat leveling, and final top-coat finishing.

Parallel to this, the 5052 sheet-metal base was laser-cut, bent, drilled, and assembled with defined mounting points. The combined structure achieved controlled geometry, low weight, and reliable handling for repeated display use.

Technician sands full-scale foam master for CT housing.

Benefits

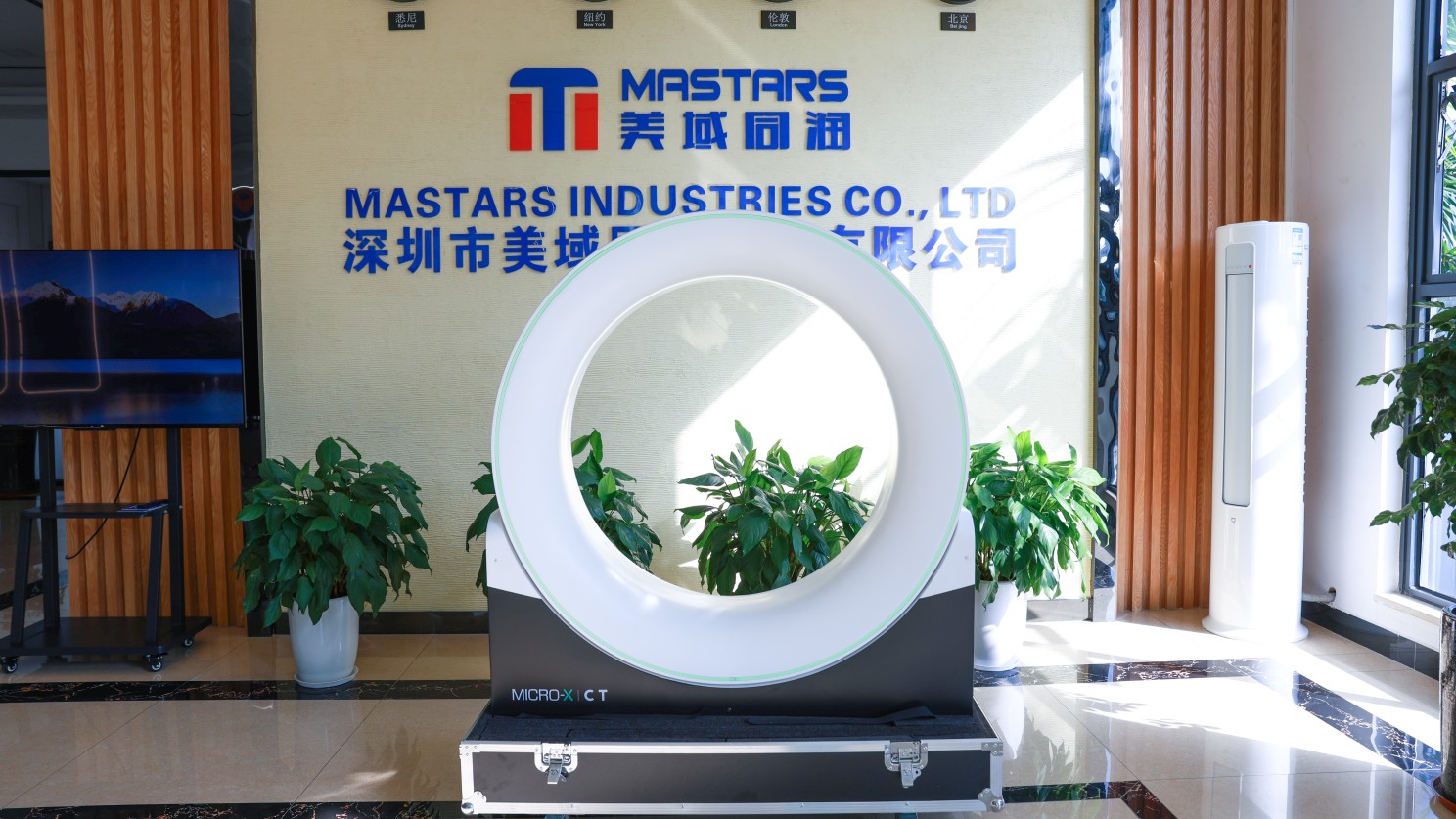

The hybrid shell-and-foam build provided a fast, low-risk path to a full-scale CT ring light display.

✅ Full-scale geometry without committing to tooling

✅ Lightweight but rigid structure for safe manual handling

✅ Smooth, paint-ready surfaces with minimized seam visibility

✅ Adaptable internal support concept for future versions

✅ Defined sheet-metal base improves alignment and repeatability

Our engineering team inspects the finished ring light display before delivery.

Use Cases

The processes and manufacturing solutions involved in the production of this display light by Mastars are equally applicable to the following scenarios:

- Medical imaging display housings, diagnostic ring lights

- Full-scale shells for carts, consoles, and treatment systems

- Oversized models for showrooms, events, and investor demos

Full-scale CT ring light prototype displayed in Mastars lobby.

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.