Background

For a program with a U.S.-based medical enterprise customer, Mastars was asked to design and manufacture multi-cavity hot runner molds for medical plastic parts used in regulated healthcare environments. We are an ISO 13485 certified manufacturer, which supports projects that must align with medical quality and regulatory requirements. These components include clips, housings, caps, and other functional parts that interact with patient identification and clinical workflows. They must keep tight tolerances, clean surfaces suitable for printing and labelling, low particle generation, and stable mechanical behavior over long production runs.

Buyers also need a clear validation path, including traceable materials, defined process windows, and mold designs that run reliably in cleanroom or controlled environments. Multi-cavity hot runner tooling is often the only practical way to combine high output, controlled unit cost, and strict quality requirements on such programs.

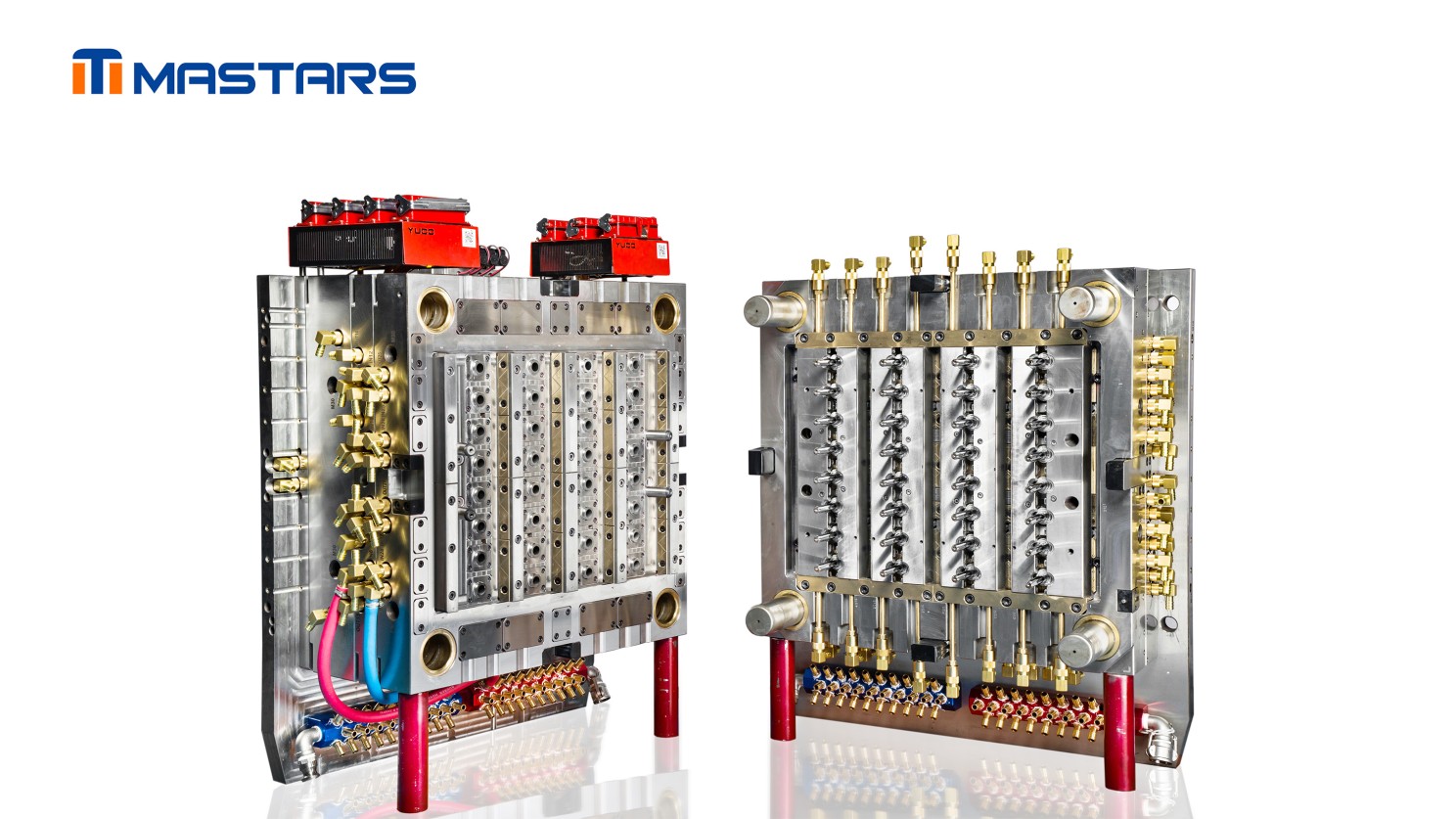

Array of heated nozzles and shafts for a high-cavitation hot runner mold being prepared at Mastars

The Challenge

The challenge for medical injection molding was to increase cavitation while keeping cavity-to-cavity performance stable over time. Simply duplicating a single-cavity design is not enough. The hot runner manifold, nozzle selection, and gate design must deliver balanced filling so that each cavity sees similar pressure, temperature, and shear.

Cooling channels have to remove heat quickly but uniformly, so parts do not warp or show sink marks, especially in areas that carry labels or printed information. Tool steels and surface treatments must withstand frequent cleaning with aggressive agents without losing dimensional accuracy or surface quality. At the same time, Mastars must hold tight tolerances across many inserts and plates, integrate hot runner and cooling systems in limited space, and provide documentation for validation, maintenance, and future engineering changes.

Multi-cavity hot runner manifold with electrical connectors under assembly.

Mastars Solution

We took full responsibility for the mold design and build. The engineering team started with design for manufacturability reviews, checking part geometry, wall thickness, tolerances, and resin data. Based on this, they defined cavity number and layout, selected hot runner types, and positioned gates to protect critical functional and appearance areas. Three-dimensional mold design focused on robust parting lines, optimized cooling circuits, venting, and maintainable manifolds and nozzles. Then we used precision CNC machining, grinding, and EDM to produce cores, cavities, and plates to tight dimensional limits. During assembly and tryout, structured checklists were used to control build quality.

Finally, our team conducted mold trials, adjusted the process window, and measured key dimensions across all cavities, so the customer received both a professional multi-cavity hot runner mold and a proven molding process.

Valve and pressure control block for the hot runner system on Mastars' mold assembly line.

Benefits

A well-engineered multi-cavity hot runner mold from Mastars helps buyers balance quality, throughput, and total cost in medical plastic programs.

✅ More parts per hour on each press, improving the use of existing molding capacity.

✅ Stable cavity-to-cavity dimensions and appearance, reducing scrap, sorting, and complaint risk.

✅ Lower material waste by eliminating cold runners and reducing the need for regrind.

✅ Shorter cycle times through efficient cooling and controlled mold temperatures.

✅ Easier cleaning and preventive maintenance, supporting frequent changeovers in controlled environments.

Close-up of the hot runner manifold and nozzle interface with wring and sensors on this medical mold.

Use Cases

The same mold design and manufacturing capabilities from our injection molding team can support other sectors that rely on precise, repeatable injection molded parts.

- Consumer and personal care: bottle caps, flip-top closures, dosing caps, and pump components for skin care, hair care, and household liquids.

- Industrial and laboratory: fluid connectors, filter housings, valve bodies, and sensor housings for process equipment, diagnostics, and analytical instruments.

- Automotive interiors: decorative trim inserts, functional clips, and connector housings that require stable dimensions and consistent surface appearance.

Fully assemble the multi-cavity hot runner mold set, showing manifold, cooling, and cavity layout. Licensed by client.

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.