Background

Aerospace heat-sink components must manage thermal loads while maintaining tight dimensional control across complex internal paths. Metal additive manufacturing enables internal routing, thin-wall structures, and optimized cooling efficiency that conventional machining cannot provide.

For this build for our USA client, 316 stainless steel was selected for its thermal stability, corrosion resistance, and predictable print behavior.

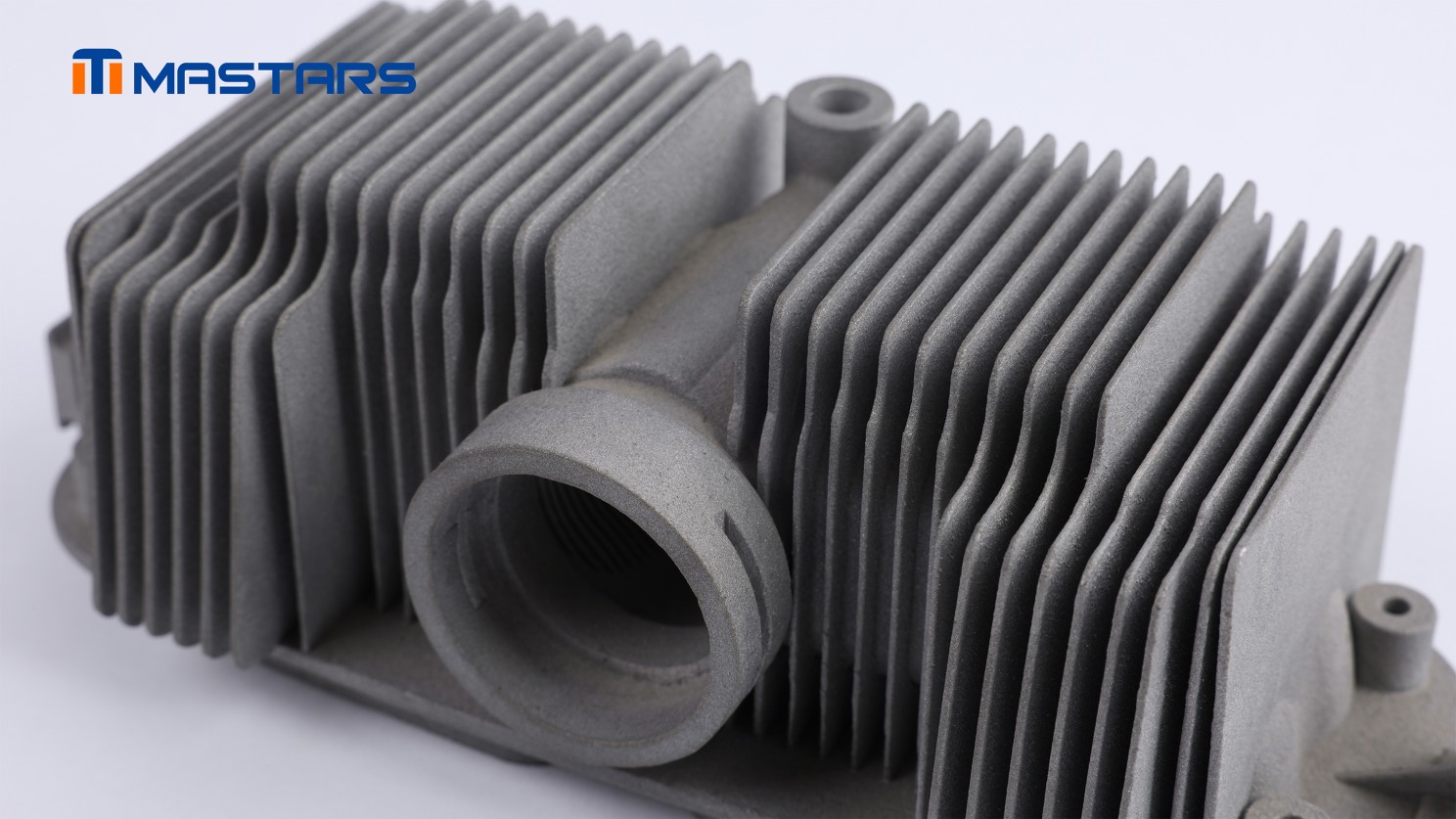

Base part of the heat sink,

The Challenge

Aerospace heat-sink components impose extreme accuracy requirements. Thin fins, narrow cavities, and deep channels demand tight tolerances across the entire part. Internal threads must maintain precise geometry and surface quality to guarantee sealing, torque reliability, and consistent assembly behavior. Maintaining this accuracy is difficult due to thermal distortion, powder characteristics, and post-processing limitations.

Caliper inspection checks fin thickness and spacing.

Mastars Solution

Mastars applies a disciplined engineering workflow to meet—and exceed—these requirements. Printing strategies are tuned for thermal balance, reducing distortion in thin-wall zones.

Support structures are designed for rigidity and clean removal. After printing, surfaces are refined through controlled machining and deburring to achieve thread precision and sealing performance. Dimensional checks throughout the process reflect Mastars’ craftsmanship and commitment to surpassing customer expectations.

316 stainless heat sink, as-printed fin array.

Benefits

Summary: A controlled additive-plus-finishing method ensures stable geometry and predictable performance.

✅ Accurate thin-wall and internal channel features

✅ High-precision internal threads for sealing and torque reliability

✅ 316 stainless-steel durability for thermal and corrosion environments

✅ Consistent dimensional control across batches

✅ Predictable post-processing for verification and inspection

Metal PBF printer building stainless heat sink.

Use Cases

The manufacturing processes and solutions for this radiator by Mastars are equally applicable to the following scenarios:

- Aerospace thermal modules and heat-sink structures

- Cooling blocks for instrumentation or optical equipment

- Complex housings with internal channels and thread-critical interfaces

Internal channel ports and thin-fin geometry.

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.