This project came from an Australian customer in a niche, high-end consumer segment: custom all-aluminum keyboards. A single unit can sell for hundreds of US dollars, so the enclosure must look and feel “luxurious.” That means Mastars had to deliver tight visual standards, consistent fit, and multiple finish options.

For low-volume premium products, surface quality is not a bonus feature—it is part of the product function and brand value.

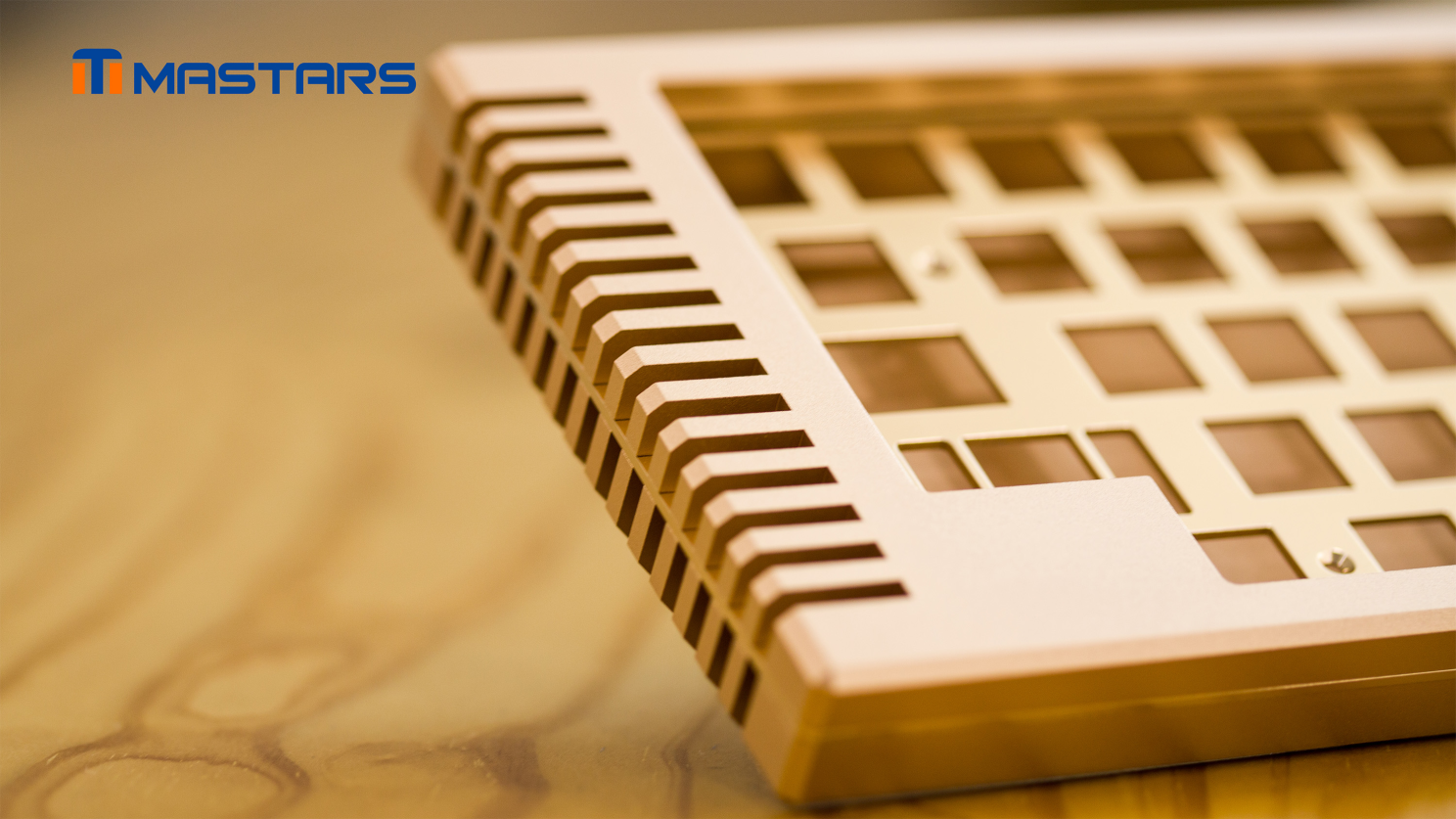

Sandblasted, anodized aluminum keyboard housing coner showing clean edges and milled fins.

Pcision CNC details: tapped fasterner seat and pocet, consistent anodized color and texture.

CNC, tapping, blasting, and anodizing in one stop

Mastars delivered one-stop workflow: prototyping, CNC (computer numerical control) machining, tapping, sandblasting, color anodizing, metal parts, and full assembly. The enclosure starts with CNC machining to form the outer geometry and internal cavities, then tapping creates reliable threaded joints for repeated builds. Sandblasting is used to create a uniform matte texture and hide minor machining marks. Anodizing with color dye then provides corrosion resistance and a premium visual finish.

The key difficulty is repeatability: the same edge sharpness, the same surface feel, and the same color tone from unit to unit. Packaging planning was aligned to protect the cosmetic surfaces during shipping and to match the customer’s premium unboxing expectation.

Retail-style box design protects small-batch keyboard kit during shipping and unboxing.

One-stop delivery lowers cosmetic and fit risk

Working with a Mastars, a true one-stop partner, reduces handoffs and keeps outcomes stable in small batches.

✅ Faster iteration from prototype to small batch

✅ More stable fit between CNC parts during assembly

✅ Cleaner surface consistency after sandblasting

✅ More repeatable color results from anodizing dye

✅ One schedule for build, assembly, and packaging

Anodized metal accent keycaps in multiple colors, ready for boutique keyboard builds.

Three industries and more need premium small batches

This workflow fits programs that need high cosmetic quality and tight assembly repeatability.

- Premium consumer electronics enclosures with anodized finishes

- Industrial handheld instruments and test equipment housings

- Camera and imaging accessories requiring refined metal cosmetics

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.