Background

A motorcycle instrument cluster is a safety-critical interface. Riders rely on it for speed, warning lights, and navigation prompts at a glance. The front LCD cover and housing must keep the display clear, remain stable under vibration, and resist sweat, rain, UV exposure, and frequent handling. Fit is equally important. If the cover and housing do not seat correctly, the cluster can show light leakage, rattling, or uneven cosmetic gaps.

Finished instrument cluster with mirror bezel, tight fit and clean screw seats.

The Challenge

This build requires both tight machining control and premium cosmetic finishing on two different materials.

The LCD cover is made of 304 stainless steel. It can work-harden during cutting, and it shows even tiny scratches after mirror finishing. The surface must stay flat and clean through mirror polishing, electropolishing, and mirror PVD.

The main body is made of zinc alloy and features knurling, precision details, and a black PVD finish. Any mismatch found after coating becomes expensive because PVD is a final-stage process. At Mastars, we treat trial assembly as a quality gate before surface treatment, then verify again after coating.

Black PVD knurled housing and mirror-finish stainless cover, ready for trial assembly.

Mastars Solution

For the 304 stainless LCD cover, Mastars completed turning roughing to establish stable roundness, then CNC finishing on critical faces and edges. Our team inspected dimensions against the drawing before any cosmetic steps. After that, we performed mirror grinding and polishing on the appearance face, followed by electropolishing to improve surface consistency and reduce micro defects that can print through coatings. The final step was mirror PVD.

For the zinc alloy housing, Mastars completed turning roughing and knurling to lock the grip pattern and main geometry, then CNC finishing on key functional features. We inspected critical dimensions, then completed appearance preparation and cleaning before black PVD.

Before any coating, Mastars conducted trial assembly with the customer’s mating parts to confirm seating, alignment, and visual gaps. After PVD, our inspectors repeated assembly checks to ensure the coating process did not change fit or cosmetic expectations. This sequence supports high-quality output while protecting delivery timing.

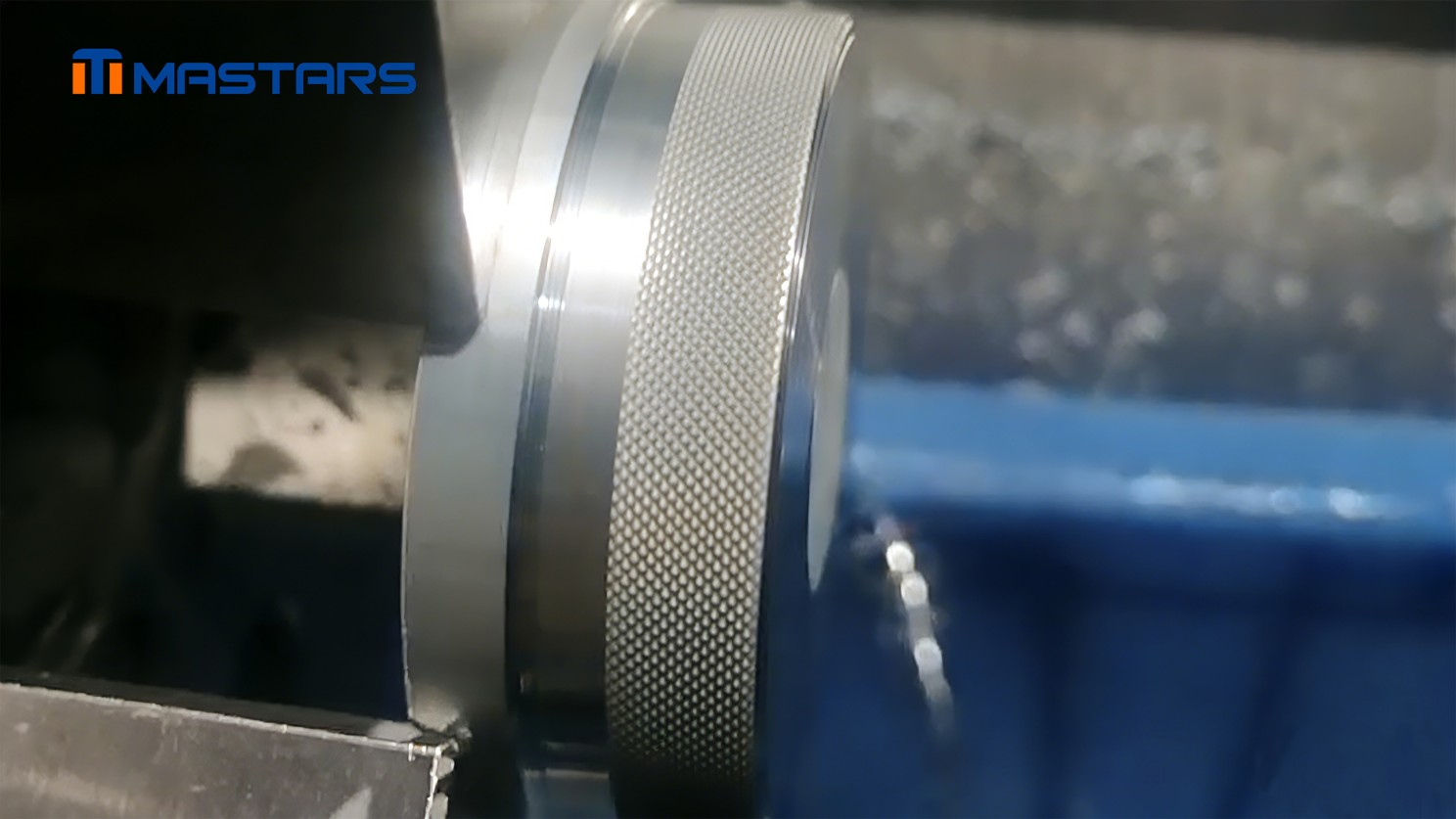

The turning and knurling process creates a consistent grip texture on the zinc alloy ring.

Benefits

Faster delivery, lower total cost, and better quality come from controlling risk before the final finish.

✅ Fast delivery through a controlled machining and finishing sequence at Mastars

✅ Lower cost by confirming assembly before PVD, reducing scrap and rework

✅ Better quality through pre-finish inspection on key datums and dimensions

✅ More stable mirror appearance supported by polishing discipline and electropolishing

Dimensional inspetion with calipers, comparing part to CAD model before coating.

Use Cases

Applicable industries for this machining and PVD finishing workflow include:

• Motorcycle and powersports instrument clusters, bezels, and control housings

• Automotive interior trim, knobs, and decorative metal parts

• E-bike and scooter dashboards and handlebar modules

• Consumer electronics housings, rings, and decorative metal covers

• Industrial control panels, instrumentation, and rugged display modules

• Premium outdoor and sports equipment with cosmetic metal parts

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.