AI Modular pump station controller for Xylem Nexicon

For Xylem, a U.S.-based water technology company, Nexicon is a modular AI and cloud platform used to manage wastewater pump stations. In this program, Mastars supported the enclosure set for a Nexicon-related pump-station controller product line.

The goal was straightforward: deliver housings that look clean, assemble consistently, and remain stable through repeated field service. In pump-station environments, the enclosure serves as a functional interface—fit, the sealing features, and long-term durability matter as much as appearance.

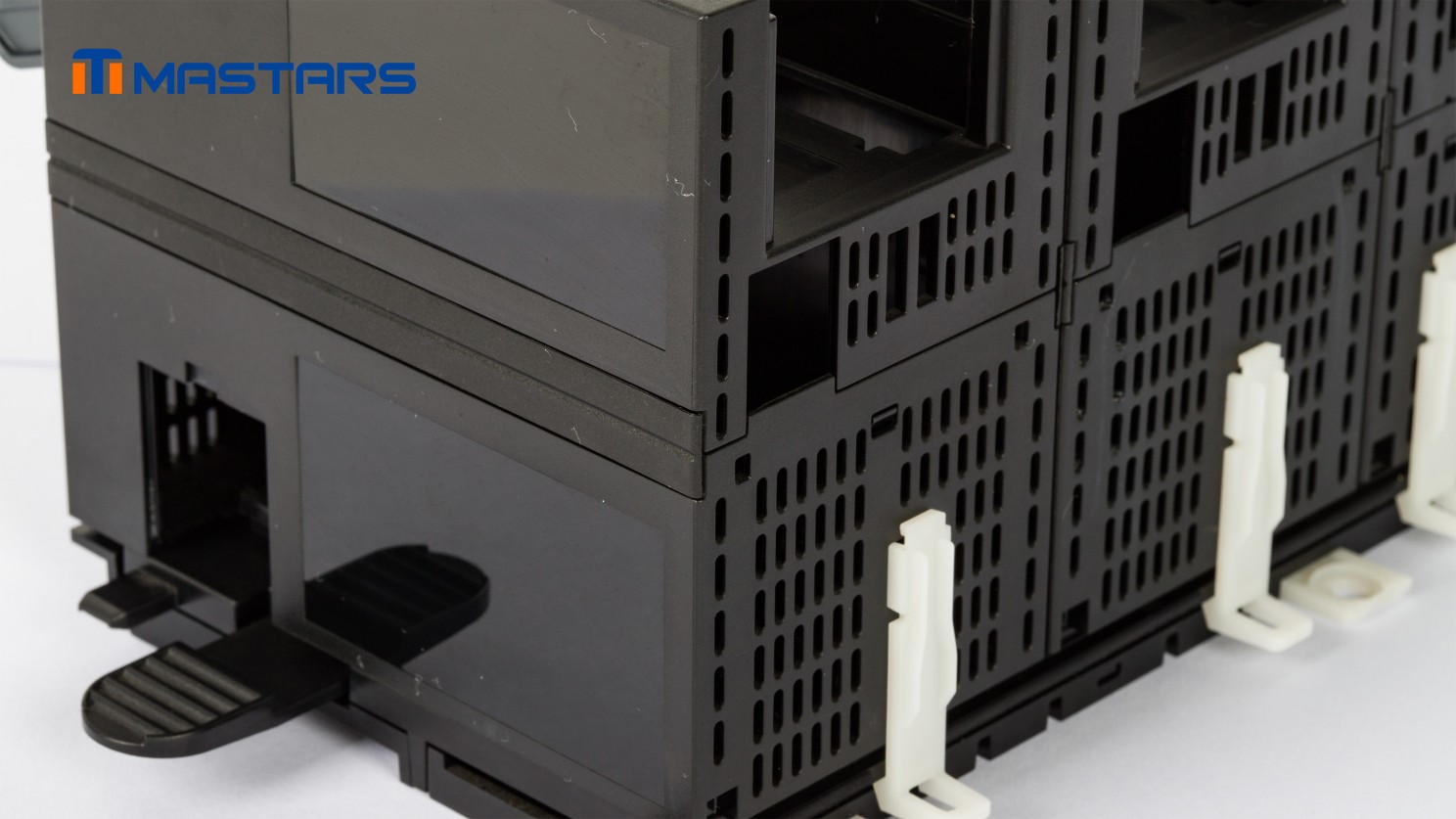

Open housing shows three module bays and hinged covers for access, wiring, and service.

Tooling-driven precision for field enclosures

For harsh field use, fit, sealing features, and long-term durability are not optional. We had to start from mold design and tool build, because enclosure performance is largely “locked in” by tooling quality and process stability. Even small plastic parts can carry high risk: latch geometry, sealing lands, screw bosses, and alignment features all affect how a modular housing closes, locks, and stays aligned over time. These details must remain stable after thousands of open/close cycles during installation, inspection, and maintenance.

If the workflow is split across multiple suppliers, tolerance stack-up, surface mismatch, and weak interfaces can appear. Small deviations may not be obvious in the first build, but they show up later as poor closure feel, inconsistent gaps, or accelerated wear at clips and mating faces. Over time, that risks compromise dimensional stability and durability—especially around clips, seals, mounting points, and module alignment features. For buyers, the cost is rarely only scrap. It is also rework, extra inspections, and longer service operations in the field.

Rear view of vented enclosure with DIN-rail feet and retaining clips for secure mounting.

One-stop from prototype to shipment

Mastars managed the enclosure scope end-to-end: prototype samples, mold design, injection molding, and delivery. Because the product family uses a modular architecture, repeatability matters more than a “good first article.” That architecture only works when housings, clips, sealing features, and mating surfaces are produced to consistent standards—lot.

We focused the build around the mechanical interfaces that buyers can verify quickly: closure feel, latch engagement, sealing feature definition, alignment repeatability, and cosmetic consistency across multi-part housings. Tooling design decisions were made to protect these interfaces, and inspection checkpoints were set against functional mating features, not only external appearance. When changes were required, a single change loop was maintained across sampling, tooling updates, and molding runs, so updates did not “drift” between vendors.

The result is a predictable enclosure built for small and medium volumes: stable fit between parts, stable interfaces for repeated service handling, and controlled appearance that matches premium industrial product expectations.

Modular controller with status LEDs and expansion backplane, designed for connected water and cloud applications. Pictured credits to Xylem.

Fewer handoffs, steadier enclosure quality

Working with a true one-stop manufacturer reduces risk across the full product lifecycle.

✅ Fewer supplier handoffs, fewer tolerance surprises

✅ One change-control loop from tooling to molding

✅ More consistent fit across multi-part housings

✅ Inspection checkpoints tied to latching and sealing features

✅ Faster ECO iterations without re-sourcing each step

Installed in pump-station control cabinets for monitoring, alarms, and remote operations. Picture credits to Xylem.

Where this approach fits best

This one-stop injection molding workflow is a strong fit for three enclosure-heavy industries:

- Industrial monitoring and sensing products: injection-molded housings that must keep the connector/latch alignment repeatable.

- Utility and building-service equipment: protective enclosures needing stable fit and durable interfaces through field maintenance.

- Modular plastic assemblies: parts relying on consistent latching and sealing features across repeated assembly cycles.

- AI server enclosures: sheet-metal or CNC frames, with injection-molded covers for a stable fit and fast service.

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.