Multi-gear shifting starts at the cassette

A bicycle cassette, the rear sprocket cluster, is a core drivetrain component that enables multi-gear shifting. It transmits torque to the rear wheel while guiding the chain across sprockets through the derailleur system. Buyers care about shift accuracy, low noise, and predictable wear—especially when the bike sees sweat, mud, and coastal corrosion.

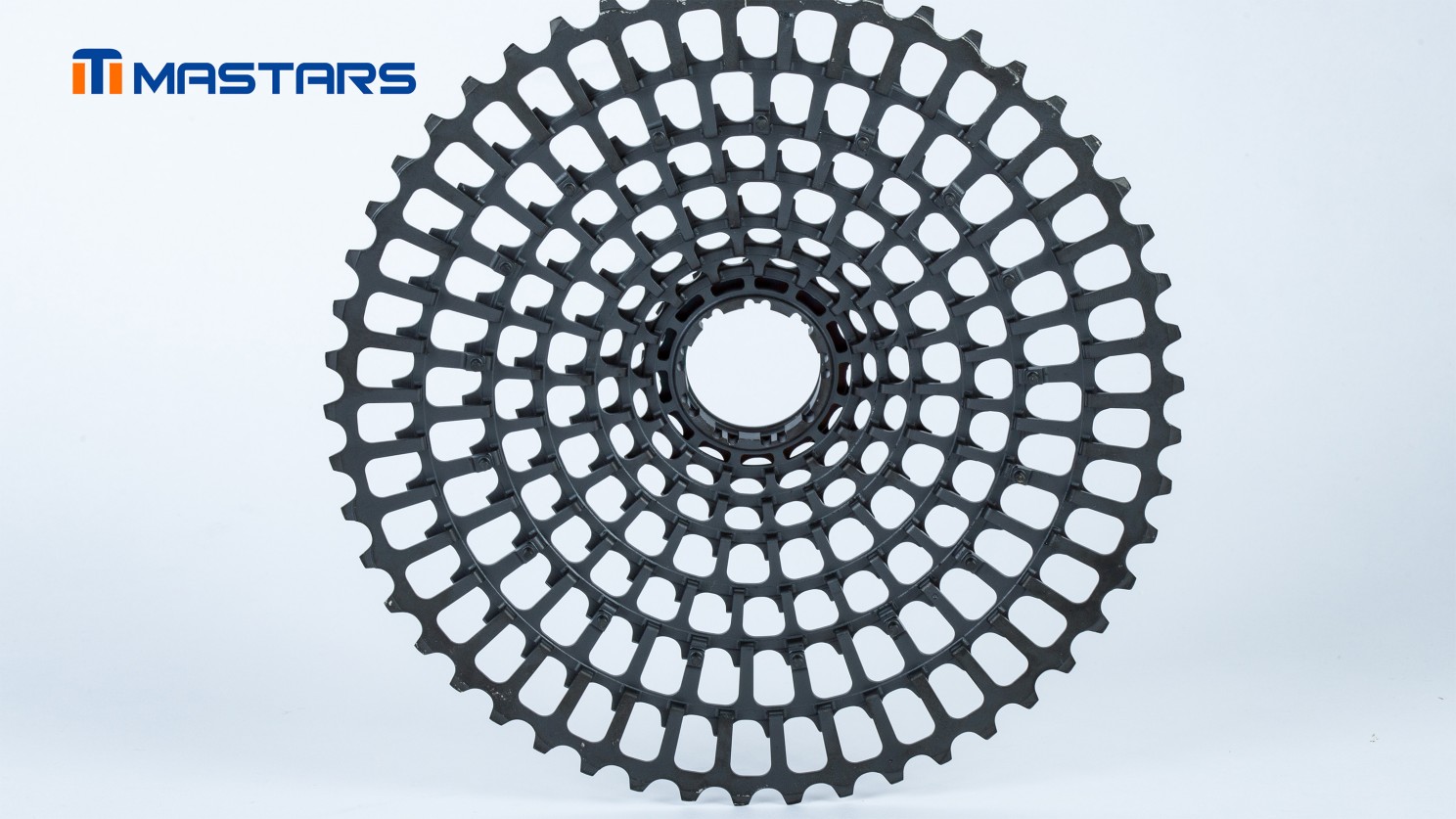

Cassette installed on rear wheel.

Thin walls, hard wear, micron geometry

Cassette manufacturing is challenging because it requires materials to be thin, hard, and precise simultaneously. Tooth form and pitch require micron-level control to prevent skip, chain climb, or unexpected shifts, often referred to as ghost shifting. Any drift in heat treatment for steel, or surface-process control for aluminum and anodized elements, can distort geometry and scrap a whole batch.

Lightweight open-lattice designs add more risk: thin sections can chatter during CNC, deform under clamping, or crack under load. If the sprocket stack is not perfectly concentric and dynamically stable, high-speed rotation creates vibration and noise. Surface finishing is not only cosmetic—matte black finishing and anodizing must also support wear and corrosion resistance within tight process windows.

Close-up of machined cassette teeth showing thin-wall pocket geometry.

One-stop five-axis CNC, controlled finishing

Mastars delivered an end-to-end, one-stop solution for our U.S. customer SRAM, covering design for manufacturability, DFM, machining, finishing, and inspection for a low-volume custom cassette program. Great difficulty does not mean not buildable—it means tighter process control and better datum planning. On our side at Mastars, we treat tooth geometry and stack stability as the two items that cannot drift, so datum planning and re-clamping limits are set early.

We used five-axis CNC milling to produce the integrated open-lattice geometry with minimal re-clamping and controlled tool engagement. Toolpath planning prioritized tooth-form integrity, burr control, and thin-wall support to reduce deformation risk. For the matte black finish and anodizing, we controlled pre-treatment, masking, and post-process checks so functional interfaces remain within tolerance while improving corrosion and wear behavior.

Five-axis milling of open-lattice cassette with high-flow coolant for chip evacuation.

Verified quality points buyers can audit

In short, we keep the part thin and light, while holding it hard, accurate, and stable.

✅ Tooth form and pitch verified to drawing-driven micron criteria

✅ Concentricity and runout controlled from defined datums

✅ Thin-wall machining strategy to reduce chatter and warp risk

✅ Matte black finish plus anodizing for wear and corrosion resistance

✅ Inspection records aligned to acceptance criteria for traceability

Transferable to other precision drives

This same capability applies to industries that need lightweight, high-precision metal parts with controlled finishing.

- Robotics and factory automation equipment

- Aerospace and unmanned systems

- Consumer electronics and premium mobility products

Mastars, the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Mastars, the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.