Many Parts, Tight Fit, Fast Changes

In medical molding projects, buyers may release many injection-molded parts at the same time. They often need a consistent fit and appearance across multiple tools, clear ownership, and fast updates after trials.

How do you keep fit, stable, and surfaces clean when the mold is compact, and trial feedback comes fast?

In this example, the client is in the U.S. medical sector and ordered many components at once. Even a single compact mold still had to match program-level standards for accuracy, fit, and output stability. The mold size was 170 × 100 × 100 mm, with a durability goal of 500k+ shots, which raises requirements for steel choice, heat-treatment control, and wear management.

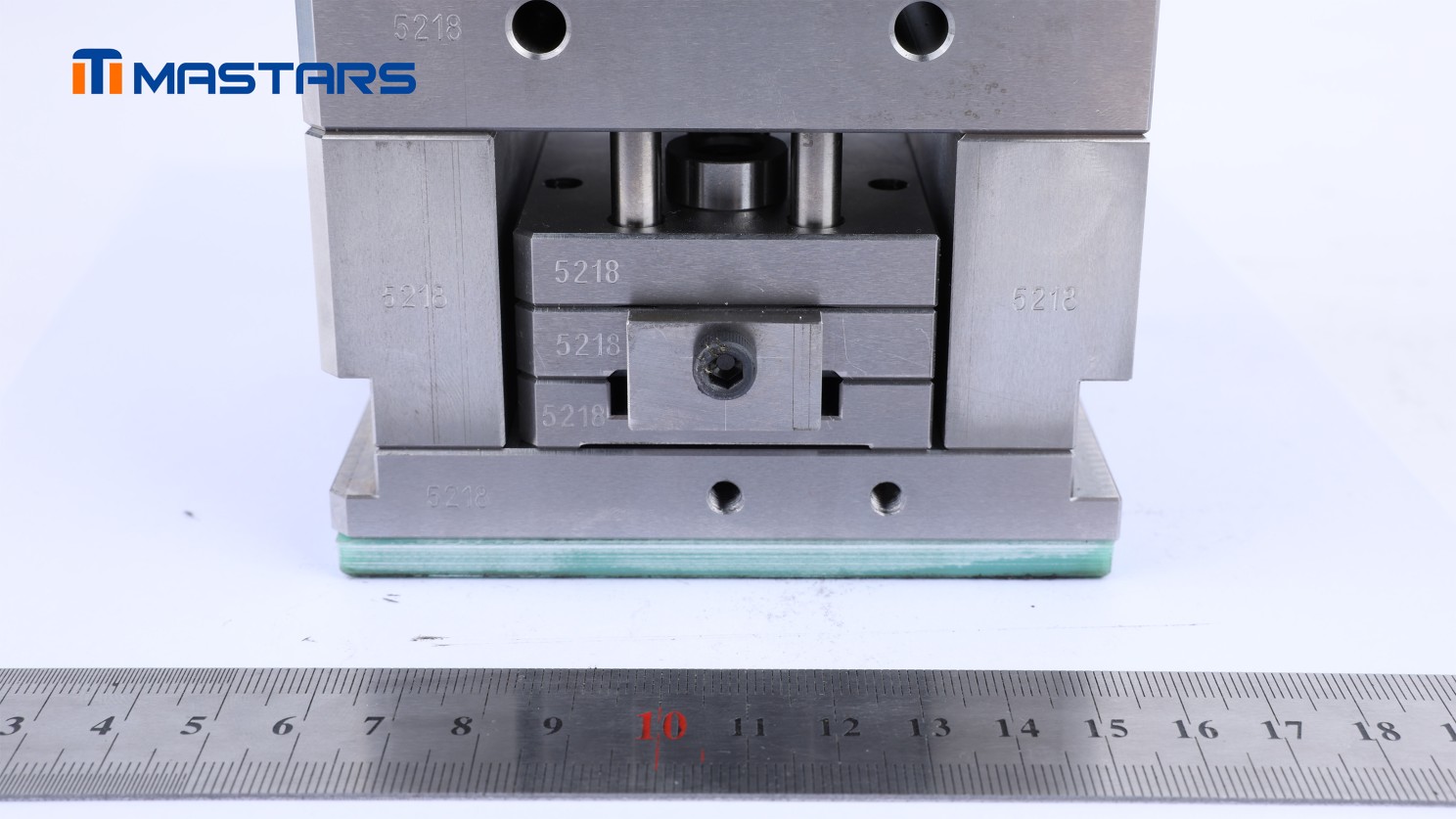

Compact medical tooling set for a U.S. program, built for consistent, repeatable output.

One Controlled Chain, Fewer Handoffs

The hard part in compact precision molds is not the size. It controls variation during handoffs and updates. When trial changes are frequent, every extra transfer can add drift to fit, wear, and surface finish.

Mastars supported this tooling with a one-stop flow: design review, mold build, trial runs, and sampling. Key steps stayed in-house to keep response fast: DFM, CNC machining, EDM, and polishing. For molding surfaces, corrosion-resistant mold steel and controlled heat treatment were used to reach HRC 52–54. This supports wear resistance and repeatable output toward a 500k+ shot target. Polishing was managed to meet cosmetic needs while protecting critical edges and fits. The result is a compact mold that still meets demanding precision and durability targets.

Tight-fit compact mold, engineered for 170x100x100 mm and 500k+ shots durability.

Client Outcomes You Can Track

Compact tooling can still meet high standards when the process is controlled in one-stop.

✅ One-stop tooling flow: review, build, trial, and sampling

✅ Key steps in-house: DFM, CNC, EDM, polishing

✅ Durability support: 500k+ shots target with HRC 52–54 surfaces

✅ More stable output: controlled fits, wear, and surface finish

✅ Faster iteration: shorter loop from trial feedback to updates

In-hosue DFM, CNC, EDM, and polishing-controlled process chain for stable edges and fit.

Where Else This Method Works

If you are in other industries, like the ones down below, the same compact, precision tooling method can help keep fit, wear, and surface finish stable.

- Automotive — sensor housings, connector covers, small valve components

- Aerospace & UAV — lightweight brackets, small housings, functional inserts

- Telecom & 5G hardware — micro enclosures, antenna-related covers, connector shells

- Laboratory & diagnostic devices — cartridge parts, caps, small interfaces

- Smart home & consumer electronics — button frames, small shells, hinge covers

Just share your drawing, material, key dimensions, cosmetic zones, and target shot life with Mastars—so the team can review risks and propose a tooling plan.

Mastars, the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Mastars, the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.