When small batches need one owner

For small-batch premium products, is it hard to find a manufacturer that can cover the full build? Yes—because “one-stop” is a real capability chain, not a slogan.

This program came from an Australian customer making an industry-leading beauty light. The request was simple but strict: many suppliers can only do parts, and large-volume factories often push for higher MOQs. The customer needed one partner to own CNC, injection molding, and full assembly—without changing the product plan to fit a factory.

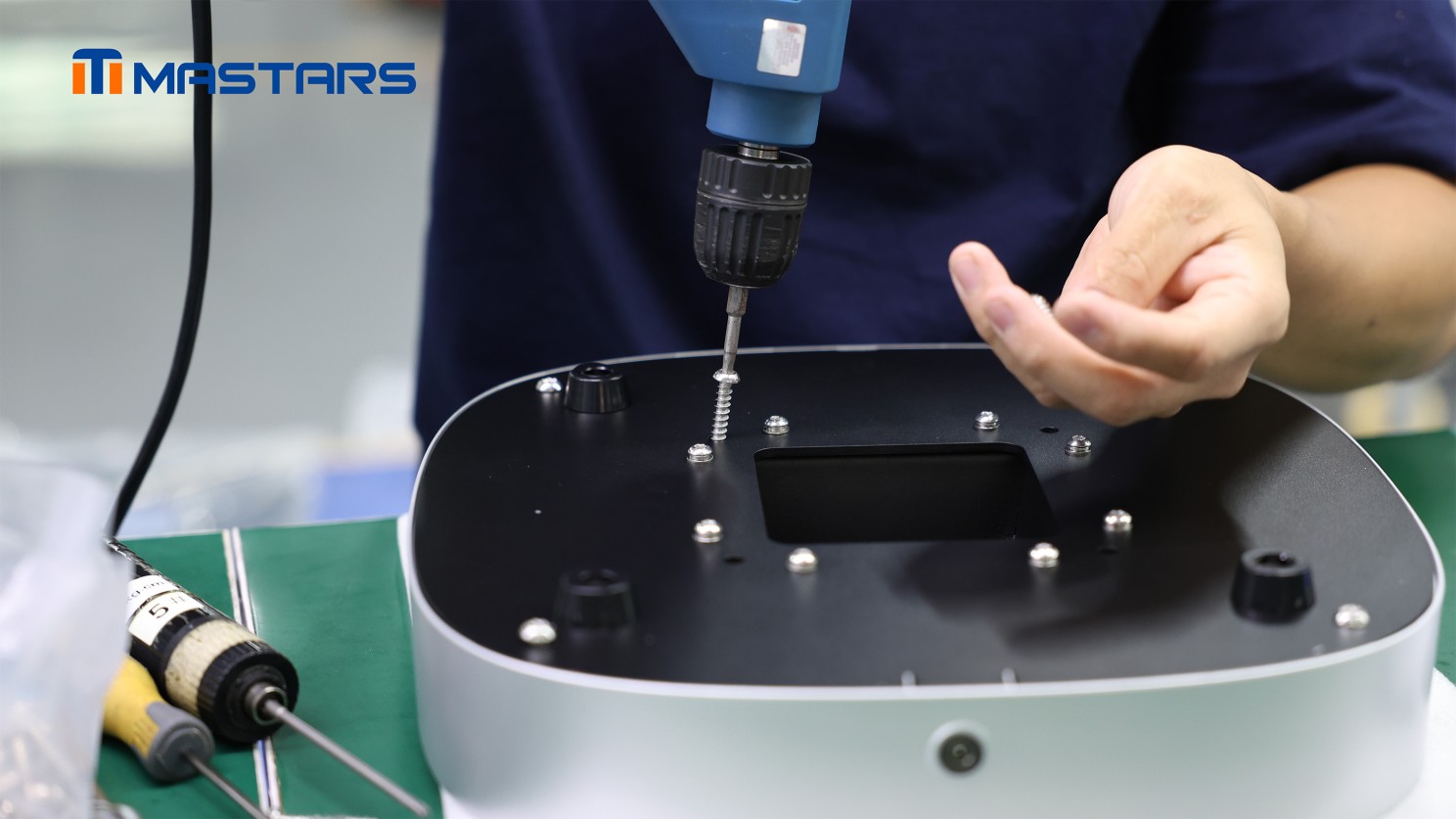

Mastars assembly line for beauty lights, ready for consistent small-batch deliveries.

One partner from parts to pack-out

True one-stop manufacturing needs in-house control across the key steps, plus one process owner and one build standard. That matters when you must hold fit, finish, and alignment across mixed materials, then repeat it reliably batch after batch.

Mastars delivered the full scope: prototyping, tooling, injection molding for plastic parts, CNC machining for metal parts, and full assembly. From parts readiness to final packing, we controlled interfaces, hardware, and the assembly sequence under one plan—so the finished product stays consistent and deliverable.

Precision screw fastening during low-volume custom full assembly, ensuring fit and repeatable quality.

What the buyer gains in production

Stable product quality, precise workmanship, and predictable lead time—without forcing high MOQs.

✅ One build owner across CNC, molding, and assembly

✅ Better fit control between plastic and metal parts

✅ Cleaner workmanship through controlled work instructions

✅ Lower rework risk by catching issues before pack-out

✅ More stable delivery with a repeatable assembly flow

Small-batch packaging for low-volume custom beauty lights, prepared for Australian shipments.

Build faster across hardware categories

If you are in another industry, the same approach applies when your product mixes materials and needs assembly—not just parts.

Common programs that benefit from CNC + injection molding + full assembly include:

- Medical devices: portable therapy equipment housings

- Consumer electronics: smart home controllers and hubs

- Industrial products: inspection lights and bench equipment

- Automotive accessories: work lights and control modules

- Personal care: skincare devices and powered tools

Do you need one manufacturer to own the full chain—from tooling to finished assembly, so that you can ship reliably in small to mid volume? Send your inquiry to us and start building your idea!

Supported with stable illumination and premium studio-ready setup. Photo credit to the brand.

Mastars, the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.