Portable audio gear needs a one-stop supplier

Small-batch premium audio products often face supply chain gaps. Is it challenging to find a manufacturer that can simultaneously handle low volume, strict cosmetic requirements, and multi-process integration?

This case features Mastars' collaboration with UK-based brand Solid State Logic (SSL) for its CONNEX portable USB microphone. CONNEX embodies the concept of "one device, multiple roles" by integrating a microphone, a USB audio interface, and Digital Signal Processing (DSP), making it suitable for calls, podcasts, vocals, and music production.

Many suppliers only handle a single process—such as etching, stamping, or assembly—while larger factories tend to push for higher Minimum Order Quantities (MOQs). The buyer required Mastars to take end-to-end ownership, minimize risks, and maintain stable quality and on-time delivery for low-volume production.

End-to-end manufacturing with acoustic performance in mind

One-stop manufacturing is only achievable when Mastars integrates key processes into a single quality management workflow, enabling fast feedback and clear accountability.

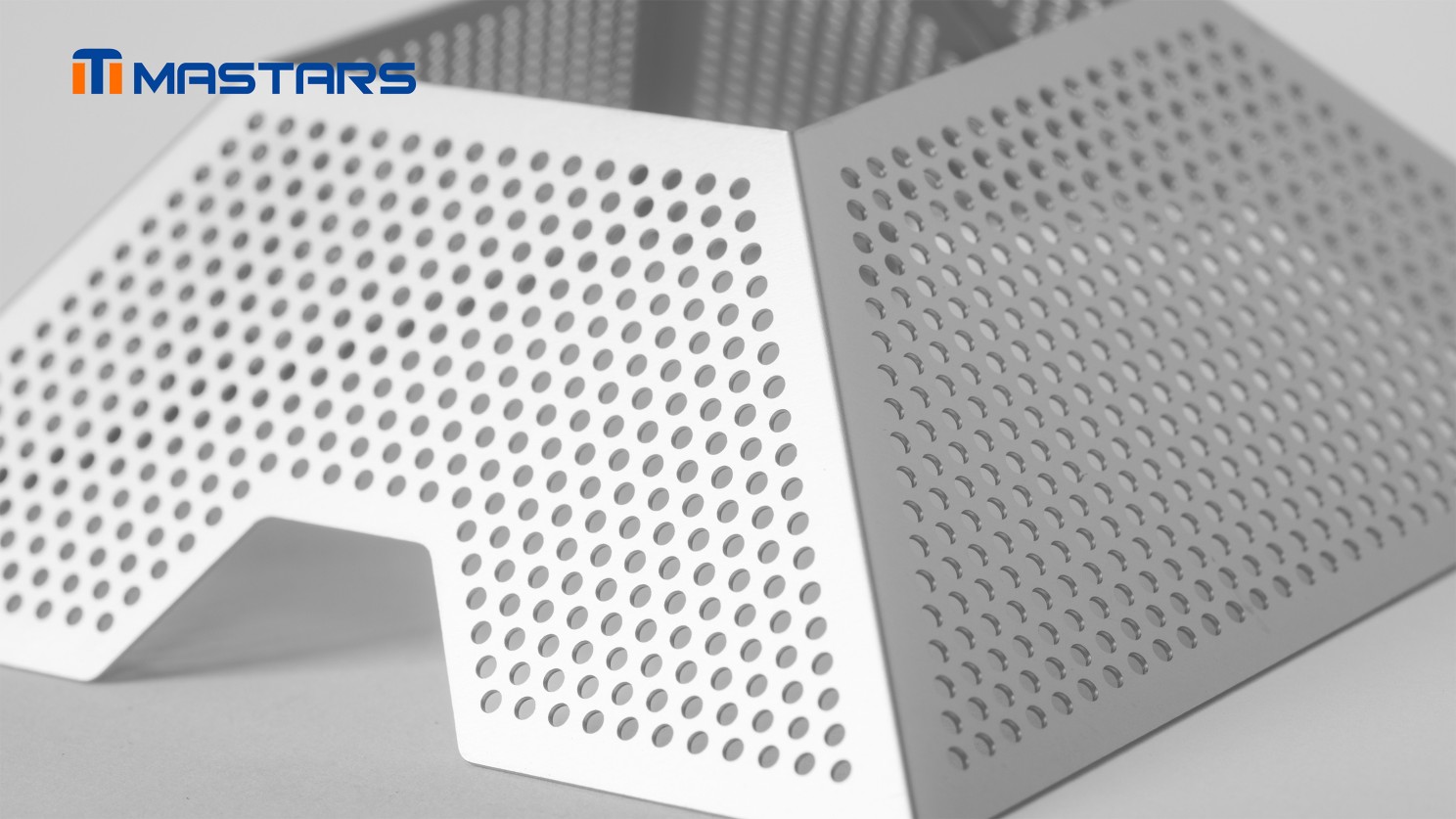

For this product, Mastars produced stainless steel components by combining etching and metal stamping. The perforation pattern must be clean and consistent, and bends must ensure alignment across multiple surfaces. Mastars strictly control edge conditions to reduce burr-induced fit issues, mitigate risks, and prevent blockages near acoustic openings.

Equipped with a multi-capsule mic array and DSP modes, the CONNEX enclosure is more than just a cosmetic component. Mastars treat the perforated cover as a functional part that protects the array, maintains unobstructed acoustic paths, and ensures a uniform appearance under studio lighting and close-up camera shots.

Beyond metal fabrication, Mastars provides full-chain support for premium low-volume hardware—from prototyping and tooling to plastic and metal parts production, and final assembly. This integrated approach reduces handoffs between suppliers, lowers mismatch risks, and enhances accountability for final product quality.

Quality stability for premium hardware

Core values delivered by Mastars: stable quality, precise craftsmanship, and reliable lead times for premium low-volume products.

✅ Etching ensures uniform hole patterns and consistent visual appearance

✅ Stamping guarantees repeatable bends and aligned surfaces

✅ Edge condition management reduces burr-induced rework and fit deviations

✅ Consistent cosmetics maintained under strong lighting and various camera angles

✅ End-to-end ownership through final assembly for clear accountability

Build faster across hardware categories

Mastars offers a complete, closed-loop manufacturing process—from hole punching and forming to final assembly—eliminating the costs and complexities of managing multiple vendors.

Target Applications

- Audio Equipment: Portable audio devices, broadcast accessories

- Professional Equipment: Medical/lab instrument housings, industrial control panels

- Consumer Electronics: Smart home device housings, sensor guards, equipment bases

Our process is equally effective for small-batch production. If your project requires high standards for hole cleanliness, forming stability, appearance consistency, or assembly accuracy, regardless of the industry, we can provide a customized solution.

What is your project's pain point? Mastars helps you overcome manufacturing challenges.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.