High Pressure Die Casting

Mastars' High Pressure Die Casting Services: Where Speed, Accuracy & Durability Meet

Get an online quote now.

High-pressure casting is a precision metal forming process that involves injecting molten metal into a die cavity at high pressure and rapid velocity. This advanced technique is widely adopted for large-scale production of high-quality metal components, boasting excellent dimensional accuracy and structural integrity.

Commonly used metals in high-pressure casting include aluminum, zinc, and magnesium—materials chosen for their lightweight properties, corrosion resistance, and good castability. These metals are transformed into critical parts that serve key industries such as automotive, aerospace, and medical, meeting the stringent performance and safety requirements of each sector.

Why Choose High Pressure Die Casting

✔️ High Efficiency for Mass Production of Light Alloy Parts

As a vital industrial process, high-pressure die casting enables the high-speed, efficient production of large volumes of light alloy parts, perfectly matching the demands of large-batch manufacturing.

✔️ Cost-Effective for Large Production Runs

Its high-speed and efficient mass production capability helps reduce overall production costs during large-scale production runs, bringing significant economic benefits.

✔️ Superior Part Quality with Consistency and Fine Finish

This casting method produces parts with minimal variability, ensuring stable product consistency, while also delivering excellent surface finishes that meet high-quality manufacturing standards.

What Makes High-Pressure Casting Stand Out Among Other Types of Casting?

✔️ Superior Part Precision and Geometry

Compared with low-pressure and gravity casting, it can produce parts with finer tolerances, thinner walls, better surface finish and less-tapered walls.

✔️ Higher Production Efficiency

It maintains excellent part quality while achieving a faster production rate, significantly outperforming other casting methods in mass production speed.

✔️ Longer Tool Life

It features increased tool service life, which is more durable than gravity casting tools that typically only last for 100,000 parts.

✔️ Outstanding Mass Production Capacity

A single tool can produce up to 500,000 parts per year, far exceeding gravity casting’s annual output of around 50,000 parts per tool.

Process of High-Pressure Casting

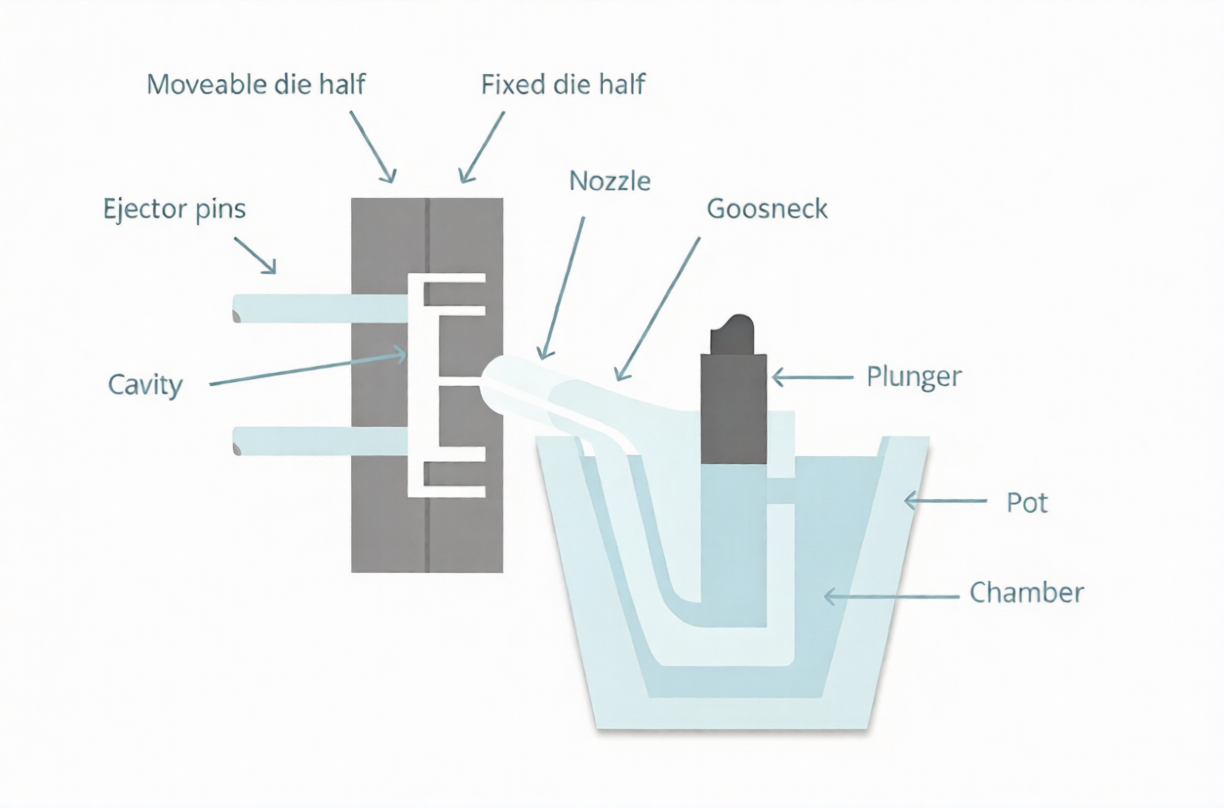

Prior to high-pressure die casting, clean the mold of impurities and lubricate it with a release agent to avoid contamination and ease part removal. Then seal the two-part mold and inject molten metal via hot or cold chamber (hot for zinc/lead, cold for aluminum/brass), with injection completed in under a second at 1,500-25,000 psi, followed by short solidification.

After solidification, open the mold and remove the part with ejector pins. Finally, trim excess material (e.g., spruce) via sawing/grinding, and the trimmed material can be remelted for reuse.

Material Options

There are many metals used in high-pressure casting. Three of the most common are listed and discussed below:

✔️ Magnesium

✔️ Zinc

✔️ Aluminum

✔️ Stainless Steel

Applications of High Pressure Die Casting

High-pressure die casting is widely used to mass-produce precise, complex metal components with smooth surfaces and consistent quality. Its main applications include:

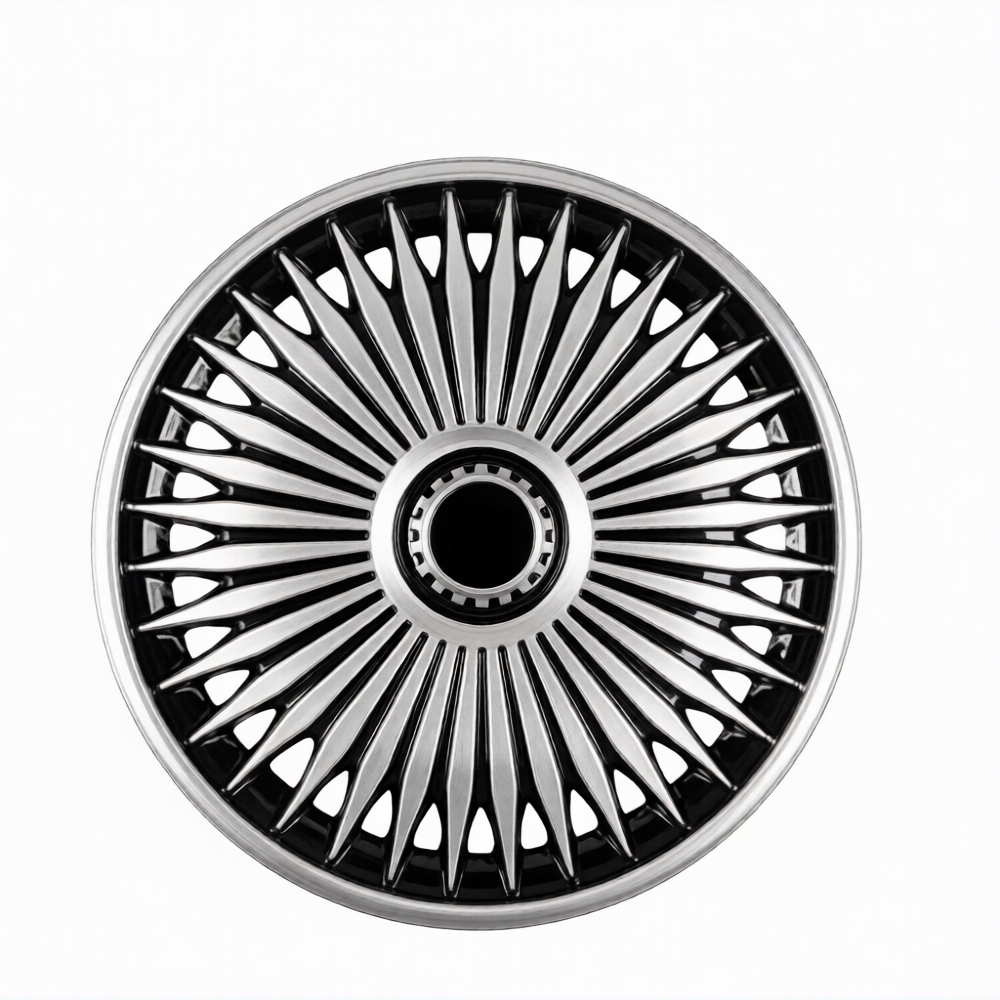

✔️ Automotive Industry

It is used to manufacture engine parts, transmission components, structural parts, wheel hubs, and suspension parts.

✔️ Consumer Electronics

It is used to produce frames, casings, chassis, heat sinks, and bodies for smartphones, laptops, and cameras.

✔️ Home Appliances

It is used to make housings for power tools and components for washing machines, dryers, and kitchen appliances.

✔️ Aerospace & Defense

It is used to create lightweight structural components, avionic parts, and sensor housings.

✔️ Industrial & Mechanical

It is used to produce pump/valve bodies, hydraulic components, and electrical connectors/enclosures.

It is ideal for high-volume production of parts requiring dimensional accuracy and good surface finish.

Accuracy of High-Pressure Casting

High-pressure casting delivers exceptional dimensional precision, achieving critical tolerances as tight as ±0.1 mm—far exceeding gravity casting (±0.4 mm) and sand casting (±1 mm). What’s more, this level of accuracy remains highly repeatable across up to 500,000 parts, ensuring consistent quality in large-scale production.

Advantages of High-Pressure Casting

One of the most significant benefits of high-pressure casting is the exceptional strength and durability it imparts to components—an advantage unmatched by other casting methods. Below are additional key benefits of this process:

· Fast production rates.

· Good surface finish and dimensional tolerances.

· Ability to create thin walls.

· Long-lasting tools.

· Ability to create complex geometry.

· Low cost for large-scale production.

Disadvantages of High-Pressure Casting

The most significant drawback of high-pressure die casting is the substantial initial investment required for both machinery and tooling. However, this cost is easily offset when production volumes are sufficiently large. Additional limitations of the process include the following:

· The higher rate of air inclusions compared to low-pressure casting.

· Not suitable for metals with a high melting point.

· Size limitations.

· Long lead time for tools, stalling initial production.

· Creates porosity internally in the metal.

Quick links

Technical video

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.