I. Basic Understanding

1. What is Plastic Tooling (Plastic Mold)?

Plastic tooling (plastic mold) is a specialized process equipment for plastic molding. It imparts specific shape, size, and surface quality to plastic materials through the mold cavity, serving as the core component of plastic processing technologies such as injection molding, extrusion molding, and blow molding. Essentially, it is a precision tooling manufactured based on product design drawings, capable of mass-producing consistent, specification-compliant plastic parts, and is widely used in the industrial production of various plastic products.

2. What are the main types of plastic molds, and what are their applicable scenarios?

According to different molding processes, the main types of plastic molds and their applicable scenarios are as follows:

• Injection Mold: The most commonly used type, suitable for thermoplastics (e.g., PP, ABS, PC) and some thermosets. It can produce 3D parts with complex structures and high dimensional accuracy, such as household appliance housings, electronic components, automotive parts, and daily necessities;

• Extrusion Mold: Used for continuous production of linear plastic products, such as pipes, sheets, profiles, films, and cable sheaths. It is suitable for mass production of long strip products with uniform cross-sections;

• Blow Mold: Divided into hollow blow molding and stretch blow molding, mainly used to produce hollow plastic containers, such as beverage bottles, oil drums, water tanks, and automotive fuel tanks. It is mainly compatible with plastic materials such as PE, PET, and PVC;

• Compression Mold: Mostly used for thermosetting plastics (e.g., phenolic resin, epoxy resin) and some thermoplastics. Suitable for producing large, thick-walled, and simple-shaped parts, such as electrical bases, brake pads, and fiberglass products;

• Thermoforming Mold: Low cost, suitable for thin-sheet plastic molding, such as food packaging trays, plastic housings, and advertising light box panels, with relatively low requirements for product accuracy.

3. What are the core components of a plastic mold, and what are their functions?

A complete plastic mold consists of two core parts and auxiliary components:

• Movable Mold and Fixed Mold: The fixed mold is mounted on the frame of the molding equipment and connected to the feeding system; the movable mold moves with the equipment's clamping mechanism to realize mold opening and closing. The cavity formed after the two are closed determines the final shape of the plastic part, and the parting surface is used to separate the movable and fixed molds and discharge gas from the cavity;

• Feeding System: Including sprue, runner, gate, and cold slug well, it is responsible for transporting molten plastic from the equipment nozzle to the cavity. The gate can also control the feeding speed and cutoff timing;

• Cooling/Heating System: Adjusts the mold temperature through water channels or electric heating elements. The cooling system accelerates the solidification and shaping of plastic, while the heating system adapts to some temperature-controlled plastics (e.g., PVC) to ensure molding quality;

• Ejection System: Including ejector pins, ejector sleeves, and ejector plates, it is used to smoothly push the molded part out of the cavity after mold opening, avoiding part deformation or damage.

II. Mold Design and Manufacturing

1. What key factors should be considered in plastic mold design?

The core is to balance product characteristics, plastic performance, molding processes, and production needs. Key factors include: ① Product structure: Optimize draft angle (to avoid sticking), fillets (to reduce stress concentration), and wall thickness (uniform distribution to prevent sink marks and warpage); design core-pulling mechanisms for complex structures; ② Plastic performance: Adjust gate position and runner size according to plastic fluidity (e.g., PA has good fluidity, PC has poor fluidity), and determine cavity size compensation based on shrinkage rate (e.g., PP has a shrinkage rate of 1.5%-2.5%); ③ Molding process: Match equipment parameters (clamping force, injection volume), design reasonable cooling/heating circuits to ensure uniform heat dissipation; ④ Production efficiency: For mass production, optimize the ejection structure, simplify mold opening/closing processes, and consider multi-cavity design (e.g., 4-cavity, 8-cavity mold) to improve productivity.

2. What materials are commonly used for plastic mold manufacturing, and how to choose?

Mold manufacturing materials are mainly steel, with non-ferrous metals used in some scenarios. Selection should be based on product output, plastic material, and accuracy requirements:

• Pre-hardened Steel (e.g., P20, 718H): Moderate hardness (HRC28-35), no post-heat treatment required, good machinability. Suitable for medium and small-batch production (output: 100,000-500,000 pieces), molds with general accuracy requirements, and compatible with ordinary plastics such as ABS and PP;

• Quenched and Tempered Steel (e.g., H13, S136): High hardness after quenching (HRC45-55), excellent wear resistance and corrosion resistance. S136 also has superior polishing performance. Suitable for mass production (output: over 500,000 pieces), high-precision products, or molds for glass fiber-reinforced plastics and corrosive plastics (e.g., PVC). Commonly used in high-demand scenarios such as medical and electronics;

• Non-ferrous Metals (e.g., Aluminum Alloy): Good thermal conductivity, short processing cycle, low cost, but poor wear resistance. Suitable for prototype trial production, small-batch production (output: <10,000 pieces), or low-hardness plastic molding.

3. What is the manufacturing process of plastic molds? What factors affect the cycle and cost?

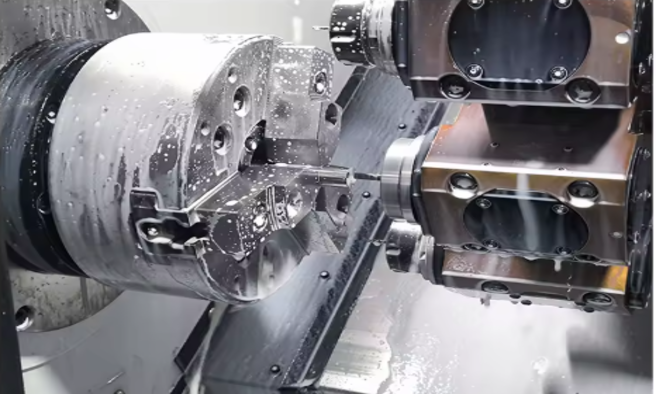

Standard manufacturing process: Product design → Mold design → Material preparation → Rough machining (turning, milling, planing) → Precision machining (CNC milling, EDM, WEDM) → Polishing → Assembly and debugging → Trial molding → Mass production.

Factors affecting the cycle: Mold complexity (7-15 days for simple single-cavity molds, 30-60 days for complex multi-cavity molds with core-pulling), processing accuracy (high-precision molds require multiple adjustments, extending the cycle), material supply (long procurement cycle for special steel); Factors affecting cost: Material cost (high price of high-quality steel), processing cost (high fees for precision machining such as EDM and WEDM), design cost (time-consuming for complex structure design), trial molding cost (additional material and labor costs for multiple trials).

4. What are the differences between multi-cavity and single-cavity molds, and what are the selection suggestions?

Single-cavity mold: Molds one part at a time, simple structure, short design and manufacturing cycle, low cost. Suitable for high-precision, complex-structured products (e.g., precision electronic components), small-batch production, or prototype trial production, effectively avoiding dimensional differences between multiple cavities; Multi-cavity mold: Molds multiple parts at a time (e.g., 4-cavity, 8-cavity), high production efficiency, low unit product cost. Suitable for mass-produced, simple-structured products with moderate accuracy requirements (e.g., daily necessities, standardized components). However, it has high design complexity, heavy mold weight, and higher requirements for the clamping force of molding equipment.

III. Mold Maintenance and Service Life

1. How to maintain plastic molds daily to extend their service life?

Core maintenance points include: ① Cleaning and maintenance: After each production run, thoroughly clean plastic residues and oil stains in the cavity and runner to avoid affecting subsequent molding after residue solidification. Do not use hard tools to scrape the cavity surface during cleaning; ② Lubrication and maintenance: Regularly apply special grease to moving parts such as guide pillars, guide bushes, ejection systems, and core-pulling mechanisms to reduce wear and jamming; ③ Rust prevention and maintenance: When the mold is idle, apply anti-rust oil to metal surfaces such as the cavity and ejector pins to avoid rust in humid environments; seal and store for long-term idleness; ④ Regular inspection: Periodically detect mold accuracy, cavity wear, and cooling water channel smoothness; promptly replace or repair loose or worn parts.

2. What are the main factors affecting the service life of plastic molds?

① Mold material: High-quality wear-resistant steel has a much longer service life than ordinary steel; insufficient material hardness and toughness easily lead to cavity wear and cracking; ② Molded plastic: Glass fiber-reinforced or mineral-filled plastics (e.g., glass fiber-reinforced PA) have strong wear resistance and accelerate cavity wear; corrosive plastics such as PVC easily corrode the mold surface and shorten service life; ③ Process parameters: Excessively high injection temperature and pressure intensify cavity stress and thermal loss, accelerating mold aging; abnormal cooling systems cause large mold temperature differences and thermal stress cracks; ④ Maintenance level: Lack of regular cleaning, lubrication, and rust prevention accelerates mold wear and rust, significantly shortening service life.

3. What are the common faults of plastic molds, and how to quickly troubleshoot and solve them?

Common faults and troubleshooting methods:

• Mold Sticking: Possible causes include insufficient draft angle, rough cavity surface, and inadequate plastic cooling; Solutions: Increase draft angle, polish the cavity surface, extend cooling time, or add an appropriate amount of release agent to the plastic;

• Clogged Cooling Water Channels: Cause uneven part cooling, extended molding cycle, and warpage; Solutions: Unclog water channels with high-pressure water flow or chemical cleaning agents, and regularly remove scale and impurities in the channels;

• Ejection Mechanism Jamming/Damage: Causes include insufficient lubrication, part wear, or foreign object jamming; Solutions: Clean moving parts, apply lubricating grease, replace worn parts, and remove jammed foreign objects;

• Cavity Wear/Scratches: Cause surface defects on products; Minor wear can be repaired by polishing, while severe wear requires welding repair followed by reprocessing of the cavity.

IV. Quality and Selection

1. How to judge the quality of a plastic mold?

Comprehensive judgment from multiple dimensions: ① Accuracy indicators: Cavity dimensional tolerance, surface roughness (the lower the Ra value, the better), uniform fitting gap between movable and fixed molds after assembly, no risk of glue leakage or mold misalignment; ② Structural rationality: The design of the feeding system, cooling system, and ejection system adapts to product needs; moving parts are flexible and smooth without jamming or abnormal noise; ③ Material and processing: Mold steel meets design requirements, processed surfaces have no tool marks or cracks, uniform polishing, and key components (e.g., ejector pins, guide pillars) meet accuracy standards; ④ Trial molding effect: Trial-molded parts have stable dimensions, no surface defects (sink marks, bubbles, warpage), reasonable molding cycle, and smooth mold opening/closing and ejection.

2. What key points should be focused on when selecting a plastic mold supplier?

① Technical capability: Possess a professional mold design team capable of optimizing product structures and solving complex molding problems; have precision machining equipment (CNC, EDM, WEDM) and complete testing equipment (coordinate measuring machine); ② Experience accumulation: Have design and manufacturing experience of molds for similar products, be familiar with the molding characteristics of corresponding plastics, and quickly respond to adjustment needs during trial molding; ③ Quality control: Establish a complete quality inspection process, with full control from material procurement, processing to assembly and debugging, and provide mold quality inspection reports; ④ After-sales service: Provide services such as mold installation and commissioning, maintenance guidance, and fault repair, and promptly solve mold problems during mass production; ⑤ Cost-effectiveness: Comprehensive evaluation based on mold cost, production cycle, and service life, avoiding substandard mold quality due to blind pursuit of low prices.

3. How does plastic mold accuracy affect product quality, and how to control mold accuracy?

Mold accuracy directly determines product dimensional accuracy, shape consistency, and surface quality: Excessive cavity dimensional deviation leads to product out-of-tolerance; rough cavity surface causes scratches and defects on the product surface; uneven fitting gap between movable and fixed molds may result in product flash and misalignment.

Accuracy control measures: ① Design stage: Precisely calculate plastic shrinkage rate, compensate cavity size, and optimize mold structure to avoid deformation; ② Processing stage: Use high-precision machining equipment, control dimensional tolerance of rough and precision machining, and perform multiple measurement calibrations on key parts; ③ Assembly stage: Strictly control the assembly accuracy of movable/fixed molds, ejection systems, and core-pulling mechanisms to ensure reasonable fitting gaps; ④ Inspection stage: Conduct comprehensive inspection of mold cavities and key components with precision equipment such as coordinate measuring machines and projectors, and promptly rework unqualified parts.

V. Cost and Application Expansion

1. What constitutes the cost of plastic molds, and how to reduce mold costs?

Cost composition mainly includes: Material cost (steel, standard parts), processing cost (rough machining, precision machining, polishing), design cost (product analysis, mold design), assembly and debugging cost (trial molding, adjustment), and management and transportation costs.

Cost control methods: ① Optimize product design: Simplify product structure, reduce complex core-pulling mechanisms and multi-cavity design to lower mold manufacturing difficulty; ② Reasonable material selection: Choose suitable steel based on output and accuracy requirements, avoiding excessive pursuit of high-priced materials; ③ Optimize processing technology: Reduce precision machining processes, reasonably plan processing paths to improve processing efficiency; ④ Batch amortization: For mass production, use multi-cavity molds to increase productivity and amortize unit mold cost; ⑤ Select high-quality suppliers: Avoid additional costs caused by multiple trial moldings and rework due to substandard mold quality.

2. What impact does 3D printing technology have on plastic mold manufacturing?

3D printing technology is mainly used for rapid mold prototyping and complex structure mold processing, with significant advantages: ① Shorten R&D cycle: Rapidly print mold prototypes (e.g., silicone molds, resin molds) and complete trial molding in 1-3 days, greatly shortening the R&D cycle of new products; ② Adapt to complex structures: Can manufacture complex cavities and cooling channels (e.g., conformal cooling channels) that are difficult to achieve with traditional processing, improving mold cooling efficiency and product quality; ③ Reduce small-batch costs: For small-batch production, 3D printed molds do not require high precision machining costs, resulting in lower costs; Limitations: Printed molds have insufficient wear resistance and hardness, making them difficult to meet mass production needs. Currently, they are mostly used for prototype trial production, small-batch production, or mold part processing.

3. What special requirements do different plastic materials have for mold design and use?

Special requirements for common plastic materials: ① High-fluidity plastics (e.g., PA, PE): Optimize runner and gate design, control injection speed to avoid flash, and compensate cavity size considering high material shrinkage; ② Low-fluidity plastics (e.g., PC, PMMA): Increase runner cross-section, optimize gate position, increase injection temperature and pressure, and polish the mold cavity to high smoothness to avoid product shortage and surface defects; ③ Glass fiber-reinforced plastics (e.g., glass fiber-reinforced PP, PA): Strong wear resistance, so the mold cavity should use wear-resistant steel (e.g., H13), and runners and gates should be designed with large fillets to reduce erosion and wear of the mold by glass fibers; ④ Corrosive plastics (e.g., PVC): Release corrosive gases during molding, so the mold should use corrosion-resistant steel (e.g., S136), perform anti-corrosion treatment on the mold surface, and optimize the venting system to discharge corrosive gases in a timely manner.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.