I. Basic Understanding

1. What is Silicone Rubber Molding?

Silicone rubber molding is a process that uses silicone rubber materials to manufacture products through mold pressing, casting, injection, and other methods. It combines the flexibility of elastic materials with the versatility of molding processes. Silicone rubber itself has excellent properties such as high temperature resistance, aging resistance, water resistance, and insulation. The molded products can be adapted to various scenarios, mainly used for small-batch production, prototype verification, and complex structural part manufacturing. Different from traditional plastic molding (such as injection molding), it is more suitable for products requiring elasticity or special performance.

2. What are the main types of silicone rubber molding?

Common types are divided into three categories by process:

• Compression Molding: Put silicone rubber raw materials into the mold cavity and press to cure under high temperature and pressure. Suitable for products with simple shapes, thick walls, and large sizes, with low cost.

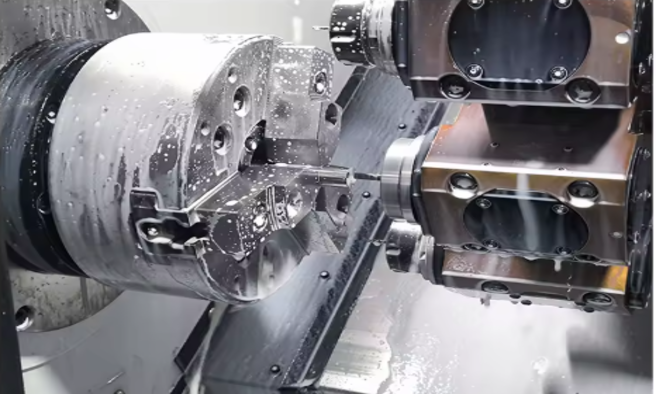

• Injection Molding: Inject molten silicone rubber into precision molds through an injection machine. It has high automation and production efficiency, suitable for mass-produced, high-precision, and complex structural products (such as seals and electronic components).

• Casting Molding: Pour liquid silicone rubber into molds and cure at room temperature or low temperature. No high-pressure equipment is required, suitable for small-batch customization, prototype production, and soft products (such as simulators and medical gaskets).

3. What are the core differences between silicone rubber molding and other molding processes (such as injection molding, 3D printing)?

The core differences lie in material properties and application scenarios:

• Compared with plastic injection molding: Silicone rubber molded products have elasticity, high temperature resistance (usually -50℃~200℃, up to 300℃+ with special formulas), and biocompatibility. Injection molding is more suitable for rigid plastics and has lower costs for larger batches.

• Compared with 3D printing: 3D printing is suitable for rapid prototyping but has low mass production efficiency and limited surface precision; silicone rubber molding enables batch replication with more stable product performance and better surface quality, suitable for the transition from prototype to small-batch mass production.

II. Material Properties

1. What are the main types of silicone rubber used for molding? What are their characteristics?

It is mainly divided into two categories: Room Temperature Vulcanizing (RTV) Silicone Rubber and High Temperature Vulcanizing (HTV) Silicone Rubber:

• RTV Silicone Rubber: Cures at room temperature, divided into one-component and two-component types. It has good fluidity and easy operation, suitable for casting molding, manual production, and small-batch products. Commonly used in prototypes, sealants, and soft simulators.

• HTV Silicone Rubber: Requires high temperature (150℃~200℃) for vulcanization and curing. It has higher mechanical strength, better aging resistance, and wear resistance, suitable for injection molding and compression molding. Widely used in industrial seals, electronic components, medical consumables, etc.

2. What are the key performance indicators of silicone rubber materials? How do they affect product applications?

Core indicators and their impacts are as follows:

• Hardness (Shore A): Usually ranges from 10A to 80A. Low hardness (10A~30A) is suitable for soft tactile parts (such as buttons and gaskets), while high hardness (50A~80A) is suitable for structural parts and seals, affecting the flexibility and support of products.

• Tensile Strength/Tear Strength: Determine the product's resistance to fracture and tearing. Industrial parts require higher strength (e.g., automotive seals with tensile strength ≥5MPa) to avoid damage during use.

• Temperature Resistance Range: Conventional silicone rubber resists -50℃~200℃, and special fluorosilicone rubber can resist -60℃~250℃, affecting the product's stability in high and low temperature environments (such as kitchen appliances and outdoor equipment accessories).

• Biocompatibility: Medical-grade silicone rubber must pass FDA and ISO 10993 certifications, applicable to human-contact products (such as catheters and gaskets). Ordinary silicone rubber is not suitable for medical scenarios.

3. Can silicone rubber molded products be dyed or added with other properties?

Yes. During production, color masterbatches can be added to silicone rubber raw materials for dyeing, resulting in uniform and non-fading colors. At the same time, functional additives can be added to achieve conductivity, thermal conductivity, flame retardancy, antibacterial properties, etc., to meet special scenario needs (e.g., conductive silicone rubber for electronic shielding parts, flame-retardant silicone rubber for aerospace accessories).

III. Process Flow

1. What is the core process of silicone rubber molding?

Taking mainstream injection molding as an example, the process is: Raw Material Preparation (silicone rubber mixing + additive addition) → Mold Preheating → Injecting molten silicone rubber into the mold cavity via injection machine → High-temperature vulcanization and curing (150℃~200℃, time adjusted according to product thickness) → Mold Opening and Part Removal → Trimming (removing flash) → Post-curing (optional, to improve performance) → Inspection and Packaging.

The casting molding process is simpler: Mold Pretreatment → Mixing liquid silicone rubber with curing agent → Pouring into the mold → Room temperature/low temperature curing → Demolding and Trimming → Finished Product.

2. What are the key requirements for mold design in silicone rubber molding?

• Parting Surface Design: It is necessary to avoid difficult-to-remove flash on products. Reasonable parting lines should be set for complex structures to ensure smooth demolding.

• Vent Grooves: Silicone rubber has good fluidity, but trace gases may be generated during vulcanization. Vent grooves (depth 0.02~0.05mm) should be set at the end of the mold cavity and corners to prevent bubbles and material shortage in products.

• Draft Angle: Due to the elasticity of silicone rubber, the draft angle can be smaller than that of plastic parts (usually 0.5°~2°) to avoid product deformation or scratches.

• Mold Material: Aluminum alloy molds can be used for small batches (low cost, fast processing), and stainless steel molds are required for large batches (wear-resistant, long service life, suitable for high-temperature vulcanization).

3. What are the common defects in silicone rubber molding? How to solve them?

• Bubbles/Pinholes: Causes include moisture in raw materials, poor ventilation, or excessive curing speed. Solutions: Pre-dry raw materials (for HTV silicone rubber), optimize vent groove design, reduce vulcanization temperature/slow down curing speed.

• Product Deformation: Causes include premature demolding, incomplete vulcanization, or uneven mold force. Solutions: Extend vulcanization time, adjust demolding timing, optimize mold structure (add locating pins).

• Excessive Flash: Causes include excessive mold clearance and high injection pressure. Solutions: Adjust mold fit clearance, reduce injection pressure and material volume.

• Rough Surface/Scratches: Causes include insufficient mold surface finish and improper use of release agent. Solutions: Polish the mold cavity, select special silicone rubber release agent (to avoid residue).

IV. Applications & Costs

1. In which industries are silicone rubber molded products mainly used?

It covers multiple fields, with core applications including:

• Electronics & Electrical Appliances: Buttons, seals, insulating gaskets, thermally conductive silicone parts (such as mobile phone waterproof rings and charging pile seals).

• Medical & Health: Medical catheters, gaskets, prosthetic accessories, baby pacifiers (requiring medical-grade silicone rubber to meet biocompatibility).

• Automotive Industry: Door and window seals, engine high-temperature resistant gaskets, shock absorbers (adapting to automotive high-low temperature and vibration environments).

• Daily Necessities: Kitchenware (silicone spatulas, baking pans), toys (soft dolls), sports equipment (handles, shock pads).

• Aerospace: High-temperature resistant seals and insulating parts (adapting to extreme environments).

2. What constitutes the cost of silicone rubber molding? How does batch size affect the cost?

The cost mainly includes: Mold Cost (aluminum alloy molds: several thousand to tens of thousands yuan; stainless steel molds: tens of thousands to over 100,000 yuan), Raw Material Cost (silicone rubber is more expensive than ordinary plastics, HTV silicone rubber is about 30~80 yuan/kg), and Processing Cost (labor, energy consumption, equipment depreciation).

Impact of batch size: For small batches (tens to hundreds of pieces), the mold cost accounts for a high proportion, resulting in higher unit cost; for medium batches (thousands to tens of thousands of pieces), the cost allocation is balanced, achieving the best cost performance; for large batches (several hundred thousand pieces+), more efficient injection molding lines are required, and the cost can be reduced through bulk raw material procurement, but mold wear should be considered (stainless steel molds have a service life of up to several hundred thousand cycles, aluminum alloy molds about tens of thousands of cycles).

3. What is the production cycle of silicone rubber molding?

The cycle is divided into stages: Mold Manufacturing (aluminum alloy molds: 3~7 days; stainless steel molds: 10~20 days); Prototype Sampling (casting molding: 1~3 days; injection molding: 2~5 days); Mass Production (injection molding: single mold cycle several seconds to tens of seconds, daily output up to tens of thousands of pieces; casting molding: single mold cycle several hours, daily output hundreds to thousands of pieces). Overall, from mold opening to bulk delivery, it takes about 1~2 weeks for small batches and 2~3 weeks for medium batches.

V. Quality & Compliance

1. How to conduct quality inspection on silicone rubber molded products?

• Appearance Inspection: Visual inspection or magnification to check for bubbles, scratches, flash, and deformation on the surface.

• Dimension Inspection: Use calipers, micrometers, projectors, and other tools to inspect key dimensions, ensuring compliance with drawing tolerances (silicone rubber molding tolerance is usually ±0.05~±0.2mm, and precision parts can be controlled within ±0.03mm).

• Performance Inspection: Sampling inspection for hardness, tensile strength, tear strength, temperature resistance, and sealing performance (such as waterproof testing). Medical products require additional biocompatibility testing.

2. What certification standards must medical and food-contact silicone rubber products comply with?

• Food-contact Grade: Must comply with FDA (USA), LFGB (Germany), and GB 4806 (China) standards to ensure no migration of toxic and harmful substances from materials.

• Medical Grade: Must comply with ISO 10993 (international) and USP Class VI (US Pharmacopeia) standards. Some implantable products require additional CE and NMPA (China) certifications.

3. What is the service life of silicone rubber molded products?

The service life depends on material type, operating environment, and stress conditions: Ordinary silicone rubber products can have a service life of 5~10 years under normal temperature, no severe friction/high temperature environments; for high-temperature, outdoor, or frequently stressed scenarios (such as automotive seals), the service life is about 3~5 years; medical-grade silicone rubber products (such as disposable catheters) are usually for single use, and reusable parts need regular replacement (in accordance with medical specifications).

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.