I. Basic Understanding

1. What is Insert Molding?

Insert molding is an injection molding process. It refers to a molding method where inserts made of metals, plastics, rubbers, ceramics, or other materials are pre-placed into the mold cavity before injection. Molten plastic material is then injected into the cavity. After the material cools and solidifies, the insert and the plastic part are tightly bonded into one piece. Its core advantage is to achieve the integrated integration of parts made of different materials, reducing subsequent assembly processes.

2. What is the core difference between insert molding and conventional injection molding?

The core difference lies in the "pre-placed insert" step: conventional injection molding only requires injecting plastic material into the mold, resulting in a single-material plastic part after molding; insert molding requires positioning the insert in advance, resulting in a multi-material composite part after molding. In addition, insert molding has higher requirements for mold positioning accuracy, material compatibility, and process parameter control, requiring prevention of issues such as insert displacement and poor bonding between the insert and plastic.

3. In which industries and products is insert molding mainly used?

It is widely used in industries such as electronic appliances, automotive manufacturing, medical devices, hardware tools, and consumer electronics. Typical products include: electronic connectors, sensor housings, automotive wiring harness connectors, mobile phone middle frame inserts, medical device handles, hardware tool grips, battery housings, etc. It is particularly suitable for scenarios that need to balance structural strength, electrical/thermal conductivity, and plastic insulation/protective performance.

II. Inserts and Materials

1. What are the commonly used insert materials, and what are their characteristics?

Common insert materials and their characteristics are as follows:

• Metal inserts: Stainless steel, copper, aluminum, iron, etc., with high strength, electrical conductivity, and thermal conductivity. They are often used in scenarios requiring load-bearing, electrical conductivity, or wear resistance (such as connector terminals and screw inserts);

• Plastic inserts: Engineering plastics of different grades (such as PC, PA, POM), used for splicing and integrating same-material or different-material plastics to improve structural consistency;

• Rubber inserts: Silicone, nitrile rubber, etc., used in sealing and buffering scenarios (such as sealing inserts for waterproof parts);

• Other materials: Ceramics (insulating, high-temperature resistant) and glass (light-transmitting, wear-resistant), suitable for precision parts under special working conditions.

2. What compatibility requirements must injection materials and insert materials meet?

The core is to ensure tight bonding between the two to avoid separation after cooling: ① Coefficient of thermal expansion matching: Excessive differences will cause internal stress during cooling, leading to cracking or loose bonding. When matching metal inserts with plastics, priority should be given to combinations with similar expansion coefficients (such as PA and copper); ② Interface adhesion: Some plastics and metals need surface treatment (such as metal galvanizing, primer coating) to enhance adhesion, or select material combinations with inherent good compatibility (such as PP and metals require special treatment, while PC and metals have good compatibility); ③ Heat resistance: Inserts must withstand the temperature of molten plastic during injection (usually 150-300℃) to avoid deformation and decomposition.

3. What are the key points in insert design?

① Structural design: Anti-slip and anti-loose structures (such as grooves, bosses, threads, knurling) should be set to increase the contact area and mechanical interlocking force between the insert and plastic; ② Dimensional accuracy: Insert tolerances must be strictly controlled (usually ±0.01-0.05mm) to avoid displacement caused by excessive fitting clearance with the mold positioning mechanism; ③ Surface treatment: Metal inserts need to be degreased and derusted, and galvanized, chrome-plated, or coated with adhesive if necessary; ④ Fillet treatment: Fillets should be made at the edges and corners of inserts to avoid plastic part cracking due to stress concentration during injection.

III. Process and Mold

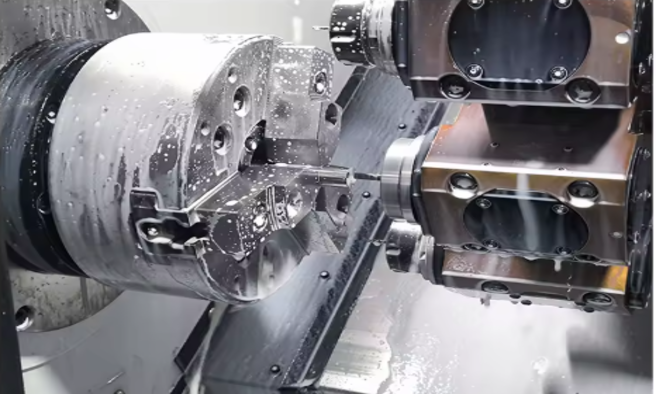

1. What is the core process flow of insert molding?

Standard process flow: Insert pretreatment (cleaning, surface treatment) → Insert positioning and placement into the mold cavity (manual or automated equipment) → Mold clamping → Injection of molten plastic → Pressure holding and cooling → Mold opening → Removal of composite plastic parts → Post-processing (deflashing, inspection). In automated production lines, insert picking and placing can be completed by robotic arms to improve efficiency and positioning accuracy.

2. What special requirements does insert molding have for molds?

① Positioning mechanism: Precise insert positioning pins, clamping grooves, or fixtures should be designed to ensure that the insert does not displace or tilt under injection pressure, with positioning accuracy usually required within ±0.02mm; ② Venting system: Due to the cavity space occupied by inserts, air pockets are likely to form. The vent groove design needs to be optimized to avoid bubbles and material shortage in plastic parts; ③ Feeding system: The gate position should avoid inserts to prevent molten plastic from directly impacting inserts and causing displacement, while ensuring uniform wrapping of inserts by plastic; ④ Wear-resistant design: The parts of the mold in contact with inserts should be made of high-strength steel (such as S136, H13) and quenched to improve wear resistance.

3. What are the key process parameters affecting insert molding quality?

① Injection temperature: Adjusted according to plastic material. Excessively high temperature may cause insert deformation and plastic degradation, while excessively low temperature results in poor plastic fluidity and insufficient wrapping of inserts; ② Injection pressure and pressure holding: Insufficient pressure leads to material shortage and poor bonding, while excessive pressure causes insert displacement and plastic part flash. Stable pressure should be maintained during the pressure holding stage to ensure tight fitting of plastic to the insert; ③ Cooling time: Sufficiently long to allow complete solidification of plastic and firm bonding with the insert. Insufficient cooling causes plastic part warpage and insert loosening; ④ Insert preheating temperature: Metal inserts can be preheated (usually 50-150℃) to reduce temperature difference with molten plastic and lower internal stress.

4. What are the differences and applicable scenarios between automated insert molding and manual insert molding?

Manual insert molding: Suitable for small-batch, multi-variety products with complex insert structures. It has low equipment investment and high flexibility but low efficiency, and positioning accuracy is easily affected by human factors. It is suitable for prototype trial production or small-batch production; Automated insert molding: Realizes automatic feeding, positioning, picking, and placing of inserts through robotic arms and vibratory feeders. It has high efficiency (up to 10-30 cycles per minute), precise positioning, and good stability. Suitable for mass production of standardized products (such as electronic connectors and automotive parts), it can significantly reduce labor costs and defect rates.

IV. Quality and Troubleshooting

1. What are the reasons for poor bonding and easy detachment between inserts and plastic, and their solutions?

Common reasons and solutions: ① Contaminated or oxidized insert surface: Thoroughly clean inserts to remove oil stains and oxide layers, and perform surface treatment (adhesive coating, galvanizing) if necessary; ② Poor compatibility between plastic and insert: Replace plastic material with better compatibility, or adjust the insert surface structure (add knurling, grooves); ③ Insufficient injection temperature/pressure: Increase molten plastic temperature, injection pressure, and pressure holding time to ensure full filling and wrapping of inserts by plastic; ④ Insufficient cooling time: Extend cooling time to allow complete solidification of plastic and bonding with the insert.

2. What are the main insert-related reasons for cracking of plastic parts after molding?

① No fillets on inserts: Stress concentration at edges and corners, requiring filleting (R-angle treatment) of insert edges; ② Excessively large difference in coefficient of thermal expansion: Replace inserts or plastic materials with more matching expansion coefficients, or preheat metal inserts; ③ Excessive injection pressure: Leading to internal stress accumulation, appropriately reduce injection pressure and pressure holding pressure; ④ Uneven cooling shrinkage of plastic: Optimize cooling water channel design to ensure uniform cooling of plastic parts; ⑤ Insert positioning deviation: Adjust the mold positioning mechanism to avoid stress cracking caused by uneven wall thickness between the insert and plastic part.

3. What are the solutions for insert displacement and tilting during molding?

① Optimize the positioning mechanism: Increase the number of positioning pins, adjust the size of positioning clamping grooves to ensure tight fitting between the insert and mold without loose space; ② Adjust feeding method: Change the gate position to avoid direct impact of molten plastic on the insert, and use side gates or pin gates instead of direct gates; ③ Reduce injection speed: Minimize the impact force of plastic on the insert while ensuring plastic fluidity; ④ Adopt automated positioning: When manual positioning has large errors, replace with robotic arm automated insert picking and placing to improve positioning accuracy.

4. What are the insert molding-related reasons for bubbles and material shortage on the plastic part surface?

① Poor venting: The space occupied by inserts causes gas to be trapped. Add vent grooves around inserts and at the end of the cavity; ② Insufficient plastic fluidity: Low temperature or slow injection speed results in incomplete cavity filling. Increase injection temperature and speed; ③ Excessively large insert volume: Causes difficulty in local cavity filling. Optimize the insert structure to reduce space occupation, or adjust the gate position to ensure uniform feeding; ④ Moisture in raw materials: Moisture in plastic materials evaporates during injection to form bubbles. Dry the raw materials in advance.

V. Cost and Selection

1. What are the cost advantages of insert molding compared to the traditional "injection molding + assembly" process?

① Reduced processes: Eliminates subsequent manual insert assembly, saving assembly workstations, labor costs, and assembly errors; ② Lower defect rate: Integrated molding avoids insert damage, loss, or improper assembly during assembly; ③ Optimized structure: Tight bonding of inserts and plastic simplifies product structure design and reduces the number of parts; ④ Improved efficiency: Automated insert molding enables continuous production, greatly improving mass production efficiency and amortizing mold costs.

2. Which products are suitable for insert molding, and which are not?

Suitable scenarios: ① Need for multi-material composites (such as metal conductivity + plastic insulation); ② Mass production requiring simplified assembly processes; ③ Compact product structure with high manual assembly difficulty; ④ Need to improve bonding stability between inserts and plastic parts. Unsuitable scenarios: ① Small-batch, multi-variety trial production (excessively high mold cost amortization); ② Complex insert structures with extremely high automated positioning difficulty (labor costs exceed process advantages); ③ Excessively large difference in coefficient of thermal expansion between inserts and plastic that cannot be mitigated by process adjustments (prone to cracking and loosening).

3. Is the mold cost of insert molding higher than that of conventional injection molding molds?

Usually yes. Because insert molding molds require additional design of precise positioning mechanisms, optimized venting systems, and feeding structures, with higher requirements for mold processing accuracy and more complex components (such as positioning pins and fixtures), resulting in a 10%-50% increase in mold design and manufacturing costs (depending on the number of inserts and positioning difficulty). However, in mass production, the additional mold costs can be quickly amortized by reducing assembly costs and improving qualification rates, resulting in overall cost advantages.

VI. Post-processing and Inspection

1. What post-processing is required for plastic parts after insert molding?

Routine processing: ① Deflashing and trimming (especially at the bonding interface between inserts and plastic); ② Surface cleaning: Remove oil stains and residual raw materials; ③ Special processing: Some products require aging testing, waterproof testing, and electrical conductivity testing before proceeding to the next process; ④ Defective product screening: Reject defective products with cracks, loose inserts, bubbles, etc.

2. How to test the bonding strength between inserts and plastic?

Common testing methods: ① Tensile test: Use a tensile testing machine to measure the force required to pull the insert out of the plastic part and compare it with the standard value to judge bonding strength; ② Torque test: For threaded inserts, use a torque meter to test firmness during torsion to avoid slipping and loosening; ③ Impact test: Simulate actual product use scenarios, use an impact testing machine to test the impact resistance of composite parts and judge whether the bonding part falls off; ④ Visual inspection: Use a magnifying glass to check for gaps and cracks at the bonding interface.

3. What factors affect the service life of insert molding products?

① Material compatibility: Whether the coefficients of thermal expansion and adhesion between plastic and insert are matched, and whether loosening occurs due to environmental temperature changes during long-term use; ② Process stability: Whether injection pressure, temperature, and cooling time are controlled reasonably, and whether internal stress exists; ③ Service environment: High temperature, low temperature, humidity, and corrosive environments accelerate plastic aging or insert rust, affecting bonding strength; ④ Structural design: Whether the anti-slip and anti-loose structures of inserts are reasonable and can withstand external forces during long-term use.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.