Chatter during CNC milling can significantly impact surface finish, leading to higher costs, delayed deliveries, and even lost orders due to poor quality. Additionally, vibration causes uneven tool wear, resulting in geometry inconsistencies and reduced tool life. Here are five fundamental techniques to combat chatter and optimize your machining processes:

1. The Right Toolholder

Standard toolholders like side-lock, double-angle collets, or ER collets often lack the accuracy and stiffness required for high-performance machining. Instead, opt for toolholders with face and taper contact designs. These provide superior rigidity and damping by engaging both the spindle's precision-ground face and taper simultaneously. Balancing all tooling components further improves surface finish, even at lower RPMs.

2. Cutting Tool Selection

Tool choice plays a critical role in chatter reduction. Key factors include substrate material, geometry, coating, and length-to-diameter ratio. While programmers may prefer larger tools, they aren’t always ideal. Using multiple tools with variable flute geometries can effectively minimize vibrations.

3. Proper Workholding

Inadequate workpiece clamping can induce vibrations and chatter. Invest in high-precision workholding systems that offer strong clamping force, ease of use, and flexibility across different machine platforms. Ensuring the part is securely held is essential for stable machining.

4. Machine Maintenance

A poorly maintained machine will struggle to achieve fine finishes and tight tolerances. Regular maintenance is crucial to address mechanical issues and ensure optimal performance. Neglecting this can exacerbate chatter problems beyond the typical causes.

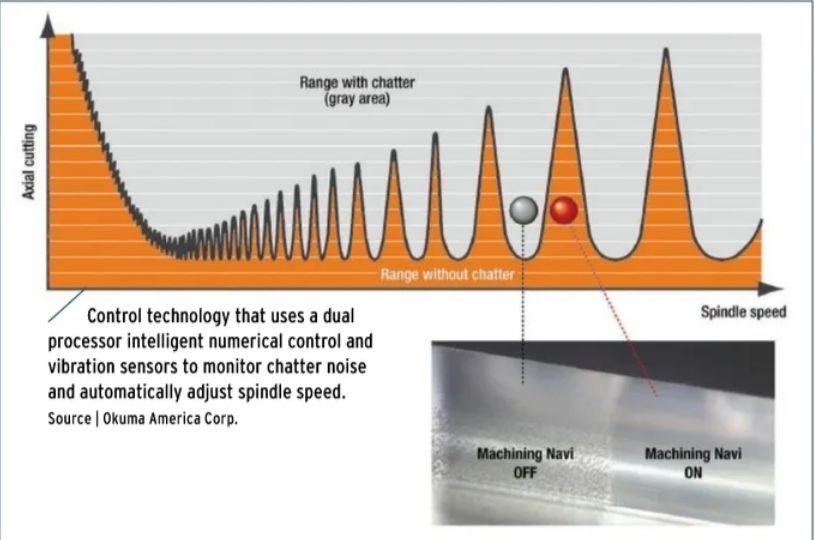

5. Control Solutions

While the above methods address many chatter sources, they have limitations. Advanced control technologies, such as smart systems, can dynamically monitor and adjust spindle speeds in real time using vibration sensors and intelligent numerical controls. This eliminates trial-and-error processes, allowing continuous high-performance operation without operator intervention.

By implementing these techniques, mold shops can enhance surface finish, reduce costs, and gain a competitive edge in precision machining.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.