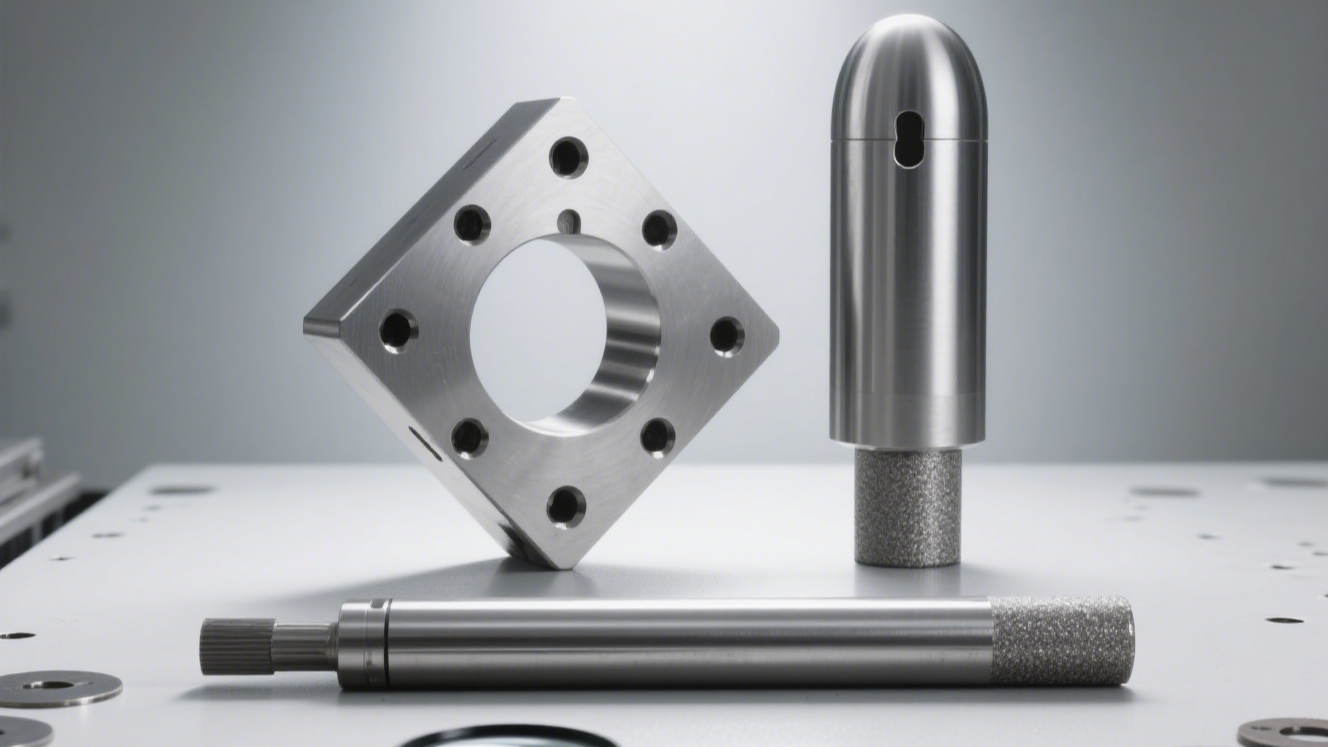

In the mold - making world, imagine a workshop cluttered not with a chaotic “pick - up sticks” mess of ejector and core pins but with a streamlined, efficient process. At Mastars, we’re all about turning that vision into reality for industrial designers and engineers. Here’s how pre - cut pins can transform your mold assembly — and why our one - stop manufacturing services (prototyping, mold design & fabrication, injection molding, 3D printing, sheet metal fabrication) are key to making it happen.

The “Pick - Up Sticks” Problem in Mold Assembly

For moldmakers, sifting through a jumble of pins to cut, measure, and fit is a time - drain. In today’s competitive market, reducing build times and costs is non - negotiable. Pre - cut ejector and core pins aren’t just a convenience — they’re a strategic solution to these industry pain points.

4 Game - Changing Benefits of Pre - Cut Pins (Backed by Mastars’ Expertise)

- Time Savings: Skip in - house cutting/measuring. With our pre - cut pins, jump straight to assembly. Whether you’re prototyping a new mold concept or ramping up production, we cut out wasted hours.

- Resource Optimization: Free your skilled team from manual pin prep. Let them focus on complex mold design, 3D - printed prototyping refinements, or high - precision sheet metal integration — tasks that truly need their expertise.

- Inventory Management: Ditch the stockpile of full - length pins. Our pre - cut solutions mean you order what you need, when you need it. Less waste, less storage hassle.

- Quality Assurance: Leverage our specialized cutting equipment (and decades of mold - making know - how). Pre - cut pins from Mastars ensure consistency, so your molds meet the tightest tolerances.

How to Choose the Right Pre - Cut Pin Supplier (Mastars’ Checklist)

Not all pre - cut pins are created equal. When vetting suppliers (or partnering with us!), look for:

- Comprehensive Inventory: A range of diameters, materials (match your mold’s needs), and styles. We stock options for every project, from delicate prototypes to heavy - duty injection molding tools.

- Precision Cutting: Exact specifications matter. Our pins are cut to the micron, ensuring a perfect fit for your mold cavities.

- Tolerance Flexibility: Different molds demand different tolerances. We offer:Standard: ±0.01 mm (0.0004″)Precision: ±0.007 mm (0.0003″)Extra Close: ±0.004 mm (0.0002″)Close: ±0.002 mm (0.0001″) Match these to your mold classification and materials (e.g., high - temp resins vs. metals).

- User - Friendly Ordering: Clear catalogs, fast quotes, and seamless integration with our one - stop services. Need a pre - cut pin for a custom 3D - printed mold insert? We make it simple.

Mastars: More Than Pre - Cut Pins — A Full - Service Partner

Pre - cut pins are just one piece of the puzzle. Our strength lies in integrating them into a seamless mold - making workflow:

- Mold Design & Fabrication: Pair pre - cut pins with expertly designed molds, optimized for your product’s specs.

- Prototyping: Test pre - cut pin assemblies in 3D - printed or CNC - machined prototypes before full production.

- Injection Molding: Scale up with confidence, knowing pre - cut pins ensure consistent, high - quality mold performance.

- Sheet Metal Fabrication: Integrate molds into larger assemblies with precision - cut metal components.

The Bottom Line: Efficiency = Competitive Edge

Moldmakers who embrace “off - the - shelf” solutions like pre - cut pins (and partner with full - service providers like Mastars) will stay ahead. Stop letting pin prep slow you down — focus on what matters: innovative design, high - quality molds, and faster time - to - market.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.