In the dynamic realm of manufacturing, plastic injection molding stands as a cornerstone technology, offering unparalleled precision and efficiency for creating a vast array of plastic components. At Mastars, our extensive experience in providing one - stop manufacturing solutions uniquely positions us to offer valuable insights into this crucial process for mechanical engineers and designers.

The Basics of Plastic Injection Molding

Plastic injection molding involves injecting molten plastic into a mold cavity under high pressure. Once cooled and solidified, the mold opens, and the finished part is ejected. This process's versatility allows for the creation of intricate shapes with tight toleances, making it a go - to for industries ranging from automotive to consumer electronics.

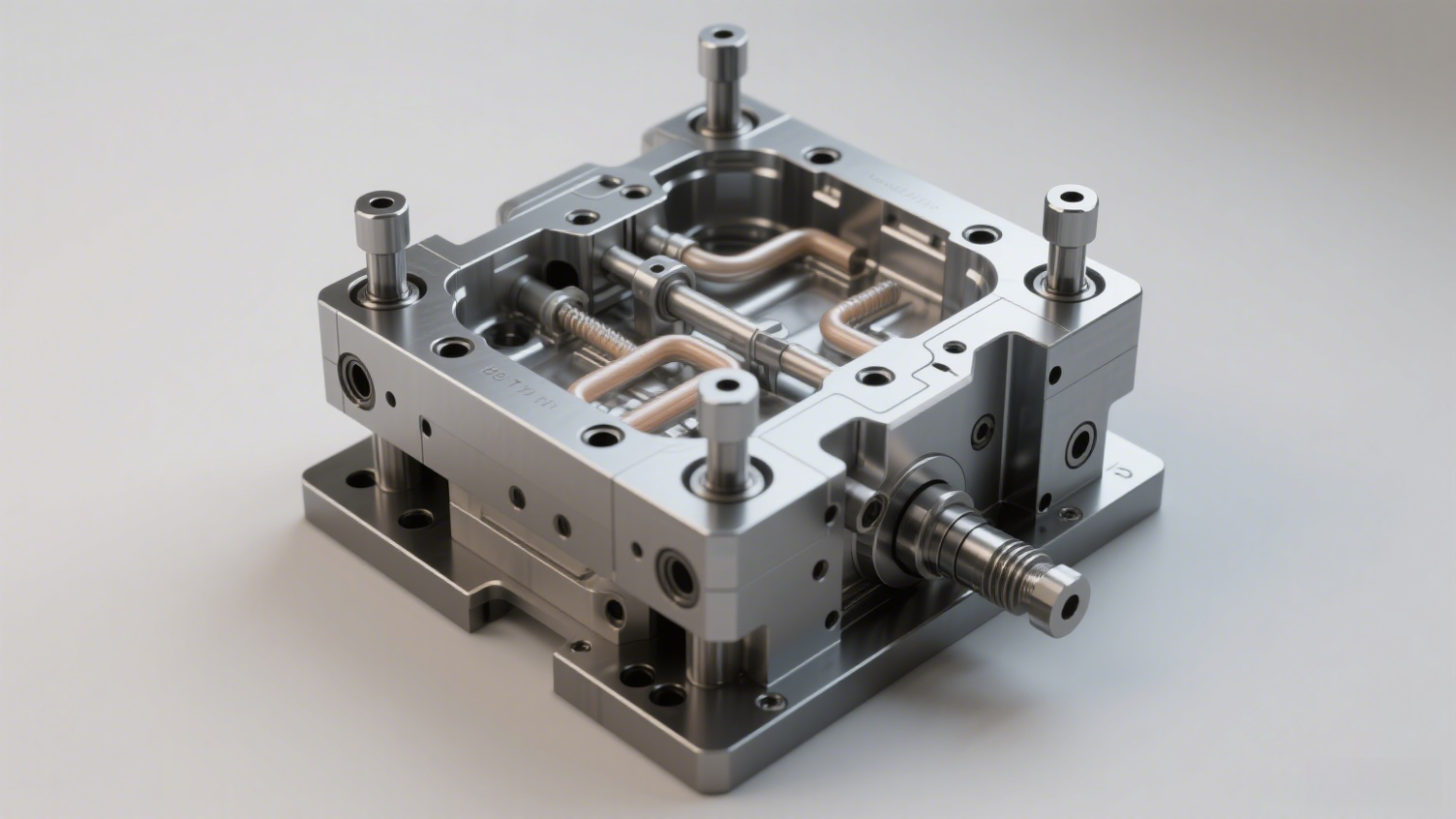

Key Components of an Injection Mold

- Mold Base: This serves as the structural foundation, typically made of high - strength steel. It provides support, alignment, and guidance for all other components within the mold.

- Core and Cavity: These are the heart of the mold, determining the part's final shape. The core forms the internal features, while the cavity shapes the exterior. Precision machining and high - quality materials are essential here to ensure accuracy and durability.

- Gating System: Comprising the sprue, runner, and gate, this system directs the flow of molten plastic into the mold cavity. The design of the gating system significantly impacts part quality, influencing factors like filling time, pressure distribution, and the formation of weld lines.

- Ejection System: After the plastic has solidified, this system, often using ejector pins, sleeves, or plates, ejects the finished part from the mold. A well - designed ejection system is crucial to prevent part damage during removal.

- Cooling System: Most injection molds have a cooling system, usually consisting of channels through which a cooling medium (such as water) circulates. Efficient cooling reduces cycle times and ensures uniform part quality by facilitating rapid and even cooling of the plastic.

Design Considerations for Optimal Results

- Part Geometry: Design parts with moldability in mind. Avoid sharp corners and deep undercuts, as these can cause filling and ejection issues. Incorporate draft angles to ease part removal from the mold.

- Wall Thickness: Maintain consistent wall thickness throughout the part. Sudden changes can lead to uneven cooling, resulting in warping, shrinkage, or other defects.

- Material Selection: Choose the right plastic material based on the part's intended application. Consider properties such as strength, heat resistance, chemical resistance, and cost. Different materials have different molding characteristics, so select one that aligns with both design and manufacturing requirements.

- Gate Location: Strategic gate placement is key. It should ensure uniform filling of the mold cavity, minimize weld lines, and avoid areas of high stress concentration.

- Ventilation: Adequate ventilation is essential to allow air and gases to escape from the mold cavity during injection. Otherwise, air pockets can form, leading to voids, burns, or other defects in the finished part.

Mastars: Your Partner in Injection Molding Success

At Mastars, we offer a comprehensive suite of services tailored to support mechanical engineers and designers at every stage of the injection molding process.

- Prototype Development: Leverage our state - of - the - art facilities, including 3D printing and CNC machining, to quickly turn your concepts into high - quality prototypes. These prototypes are invaluable for testing form, fit, and function before committing to full - scale production.

- Mold Design and Fabrication: Our team of skilled engineers uses advanced CAD/CAM software to create optimized mold designs. We fabricate molds using top - grade materials and precision machining techniques, ensuring durability and high - performance.

- Injection Molding Production: With our extensive fleet of injection molding machines, we can handle projects of any scale, from small - batch production to large - volume manufacturing. Our experienced operators and strict quality control processes guarantee that each part meets the highest standards.

- Value - Added Services: In addition to our core services, we offer value - added services such as secondary operations (assembly, painting, plating), quality inspection, and packaging. This comprehensive approach allows us to provide a complete turnkey solution for your manufacturing needs.

In conclusion, understanding the nuances of plastic injection molding and partnering with an experienced provider like Mastars can significantly enhance the success of your projects. By considering the design factors and leveraging our end - to - end services, you can bring your innovative ideas to market faster, more efficiently, and with the highest quality.

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.