Background

In the era of industrial upgrading, high-end manufacturing sectors such as aerospace, automotive, and energy demand components with complex geometries and ultra-high precision. This turbine impeller we made for an Australian client is a perfect example — its thin-walled blades, intricate curves, and tight tolerances reflect the ultimate challenge in balancing design freedom with manufacturing feasibility.

To achieve both aerodynamic performance and cost efficiency, manufacturers must rethink traditional machining strategies and embrace intelligent manufacturing.

The Challenges

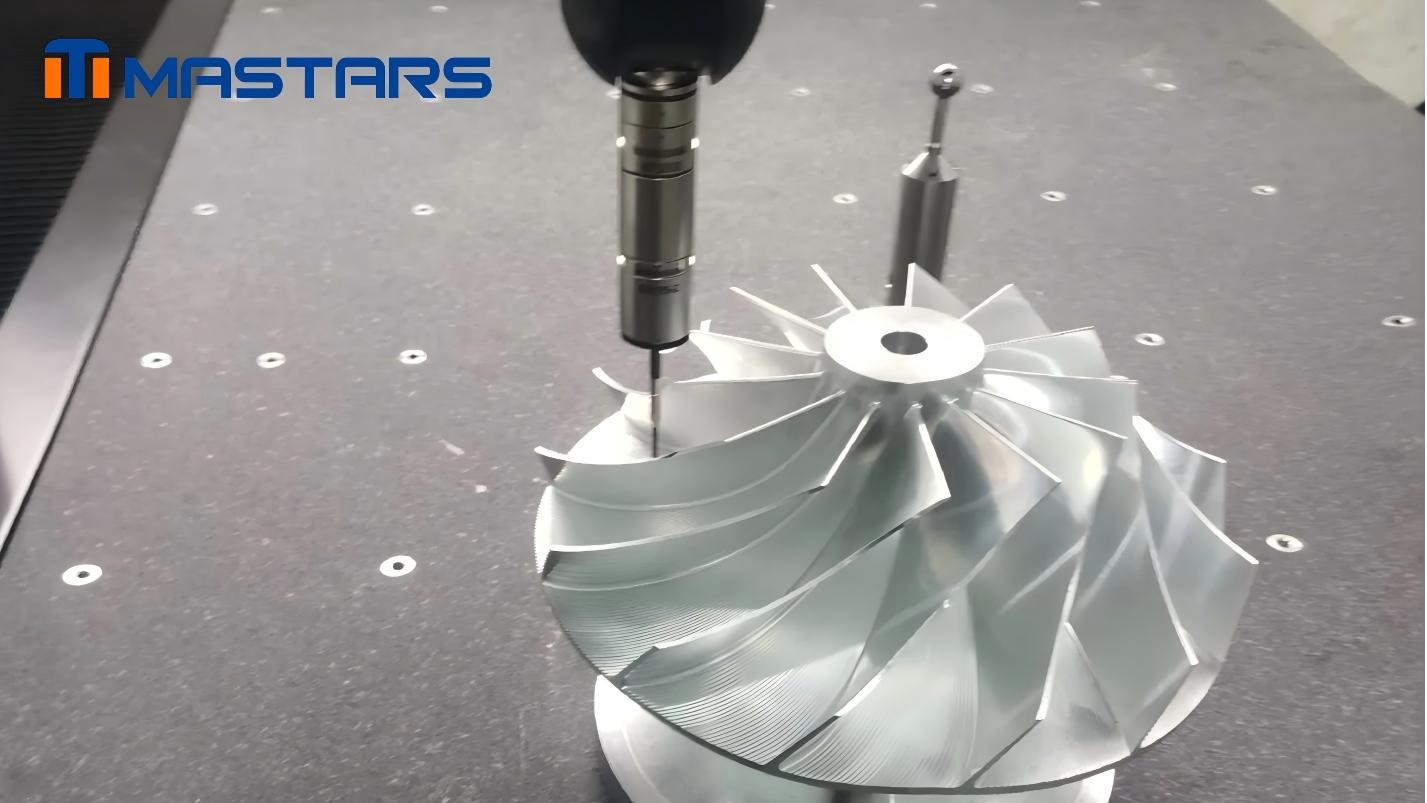

Close-up of the turbine sample, showing the precision that enables better aerodynamic and cost efficiency.

Producing turbine impellers involves multiple technical bottlenecks:

- Complex Geometry – Variable cross-sections and curved blades demand multi-axis coordination beyond 3-axis limits.

- Material Difficulty – Titanium and heat-resistant steels cause tool wear and thermal deformation.

- Low Efficiency in Small Batches – Flexible production often conflicts with rigid traditional setups.

- Quality Assurance – Maintaining dimensional consistency and balance across blades requires micron-level control.

Mastars Solution

Mastars integrates 5-axis CNC machining, additive manufacturing, and digital twin simulation to form a hybrid intelligent manufacturing system.

- Using CFD (Computational Fluid Dynamics), Mastars first optimizes the aerodynamic design of impellers.

- Then, it applies an “additive for complexity, subtractive for precision” approach — using 3D printing for near-net-shape blanks and 5-axis CNC finishing for micron accuracy.

- Finally, IoT sensors + AI algorithms monitor machining parameters in real time to ensure stability and surface integrity.

Turbine machined on a 5-axis CNC center, owned by Mastars in-house.

Benefits

Compared with traditional machining:

- Precision – Achieves micron-level accuracy meeting aerospace standards.

- Efficiency – Shortens production cycles by 30–50%.

Material Savings – Reduces waste by over 40%.

Validating dimension on CMM, ensuring each tube made by Mastars meets precision standards.

Use Cases

Mastars’ solution empowers industries, including:

- Aerospace – Engine turbine blades, impellers for air systems.

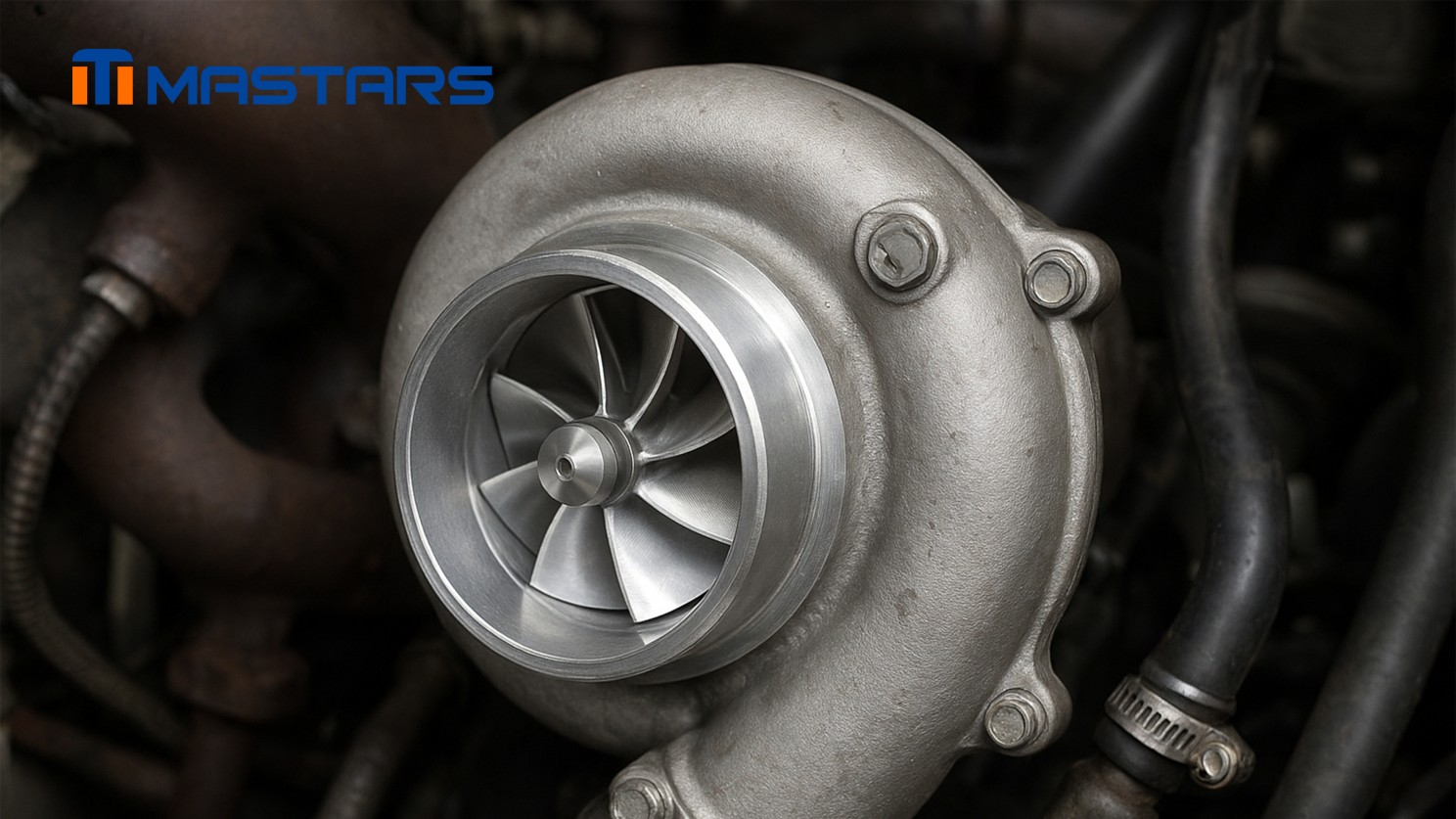

- Automotive – Turbocharger impellers, EV motor rotors.

- Energy – Gas turbines, compressor components.

- Industrial Machinery – Hydraulic pumps, cooling fans.

A case showing the usage of a turbine in part of the automotive engine system.

Mastars, to be the most trusted and reliable one-stop services partner for low-volume digital manufacturing worldwide!

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.