FMEA (Failure Mode and Effects Analysis), as a core tool for risk prevention, has been an important part of the quality systems of industries such as automotive, electronics, and machinery manufacturing for decades.

In 2019, AIAG and VDA jointly released a new "FMEA Manual", known in the industry as the 5th edition of FMEA , marking the official entry of FMEA into a new stage of structured and logical approach.

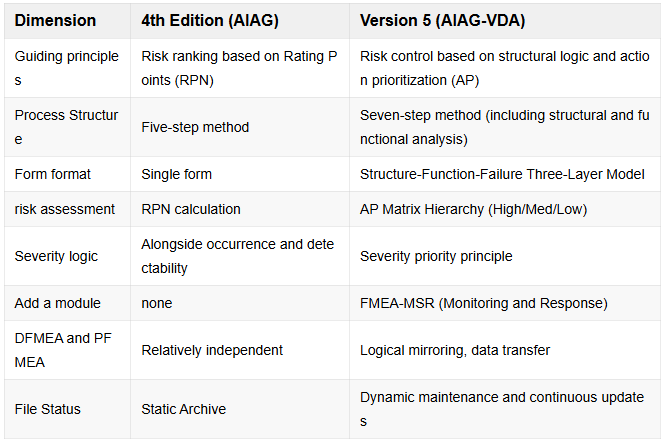

Many companies have experienced significant changes when transitioning from version 4 (AIAG version) to version 5 (AIAG-VDA joint version) : the forms, methods, logic, and focus are all different.

This article will systematically and professionally compare the key differences between the two versions of FMEA, helping quality and engineering personnel to accurately understand the core ideas and key implementation points of the new version.

I. From "RPN Management" to "Structured Risk Control"

The old version of FMEA (4th edition) used Risk Priority Number (RPN) as its core indicator.

The team calculated the RPN by scoring severity (S), occurrence (O), and detectability (D), and ranked the risks by numerical value.

This system is simple and easy to implement, but it has the following problems:

RPN product calculations are prone to a "masking effect," where high-severity failures may be diluted by low-occurrence or high-detectability failures.

The scoring is highly subjective, and the evaluation results vary greatly among different teams ;

Focusing on scores rather than root causes and solutions leads to a formalistic approach to analysis.

The new FMEA (5th edition) completely abandons the RPN mindset and introduces Action Priority (AP) , shifting the focus from score magnitude to the necessity of measures.

Its core concept is: first identify the structural and functional logic, then clarify the source of risk through causal chain analysis, use AP to determine whether action must be taken, and verify the effect of the action.

The essence of the new FMEA is to shift from scoring and ranking to structured logical analysis plus closed-loop action management .

II. Method and Flow: From 5 Steps to 7 Steps

The old version of FMEA mainly used a five-step method:

Identify the object of analysis;

Identification functions and potential failure modes;

Assess consequences, causes, and controls;

Calculate RPN;

Develop measures and conduct a review.

The new version of FMEA adopts a more systematic seven-step method , with more complete logic and clearer hierarchy:

Planning and Preparation : Define the FMEA objectives, scope, team composition, and timeline.

Structure Analysis : Establishing structural relationships between system, subsystem, and component (DFMEA) or between process, operation, and step (PFMEA).

Function Analysis : Clarify the function, performance, and interface relationships of each layer of the structure.

Failure Analysis : Establishing a logical chain of "failure consequences - failure modes - failure causes".

Risk Evaluation : Based on severity (S), occurrence (O), and detectability (D) levels, and combined with action priorities (AP), determine the key areas for improvement.

Optimization : Develop prevention and detection measures, and assign responsibilities, plans, and verification requirements.

Results Documentation : Summarize the analysis conclusions to form a complete and traceable FMEA document, and maintain consistency with the control plan.

The new version of FMEA avoids arbitrary scoring based on experience through front-end "structure + function" analysis, and ensures closed-loop performance through back-end "implementation of measures + verification", thus achieving a complete logical chain.

III. Risk Assessment: RPN is abolished, AP becomes the core

1. Older RPN method

The old version was based on RPN = S × O × D.

The sorting is simple, but the logical flaws are obvious:

Different combinations may yield the same RPN, failing to reflect the essential differences in risk .

High-severity items may be overlooked due to low scores on other factors;

Prioritizing improvements relies on human judgment, which lacks consistency.

2. New version of AP (Action Priority)

The new version uses an AP matrix table , which directly provides action priorities based on the combination of the three elements of S/O/D:

High (Action must be taken)

Medium (Recommendation to take action)

Low (Action to be considered)

The new evaluation system prioritizes severity.

Even if the probability of occurrence is low and the detection capability is high, if the risk occurs and would have a serious impact on safety, regulations, or customers, immediate action must still be taken.

The key change in the new version is that it no longer compares scores, but rather focuses on logic and measures.

IV. Analysis Structure: From "Single Table Records" to "Structured Model"

The old version of FMEA was a linear table, recording each line from function to failure mode, consequence, cause, and control.

Although concise, it lacks a sense of hierarchy, and the levels of system, component, and element are easily confused, making it difficult to trace the logical relationships.

The new FMEA adopts a three-layer model : structure-function-failure .

Structural analysis : Clarify the system composition and hierarchy;

Functional analysis : Describe the function of each structural unit and its interface relationship with the superior unit;

Failure analysis : Establish a clear causal chain, from the consequences of failure to the root cause.

This structured approach makes FMEA logic more rigorous and provides a foundation for the integration of DFMEA and PFMEA .

Key features and failure information output from the design side can be directly transmitted to the process side, realizing a closed-loop risk chain from design to manufacturing .

V. Evaluation Dimensions: Clearer definitions, focusing on control effectiveness

The new version has made substantial revisions to the definition of the three elements:

Severity (S) : More focused on security, regulations, and customer impact;

Occurrence (O) : Linked to the effectiveness of prevention and control , rather than simply probability;

Detectability (D) : Related to detection and control capabilities , emphasizing actual detection rate and response speed.

This means that the new FMEA requires assessments based on data and control logic , rather than empirical judgments.

Especially in process FMEA, the definitions of O and D are directly related to the actual effectiveness of error prevention, detection, and monitoring measures in the control plan.

VI. FMEA-MSR: A newly added monitoring and system response module

The 5th edition of FMEA introduced FMEA-MSR (Monitoring and System Response) , which is mainly applied to functional safety and monitoring scenarios during vehicle use and product operation.

It requires the team to analyze:

Can the fault be detected in actual use?

Can the system respond automatically, issue an alarm, or enter safe mode?

Are users promptly alerted and can appropriate measures be taken?

FMEA-MSR fills the gap in traditional FMEA regarding "risks during the usage phase," enabling FMEA to cover risk assessment throughout the entire product lifecycle.

VII. Changes in the Relationship between DFMEA and PFMEA

Although the old version of FMEA was divided into DFMEA and PFMEA, the two were often compiled independently and were not closely related.

The new version achieves a logical mirror relationship between the two through a unified structure and terminology:

The new version explicitly requires that the conclusions of the design FMEA must be communicated to the process FMEA and control plan to ensure that design risks can be effectively addressed by process control.

VIII. Document Maintenance and Management: From Static Documents to Dynamic Systems

Older versions of FMEAs are often regarded as client review documents and are rarely updated after projects are put into production.

The new version explicitly states that FMEA is a living document . It must be continuously updated as design changes, process variations, supplier adjustments, or quality issues arise.

New requirements:

AP is reviewed again after each change;

The control plan, process flowchart, and FMEA should be kept consistent with each version.

All improvement measures must be tracked, verified, and the results recorded.

This means that FMEA is no longer a one-time submission task, but a core process document in the company's quality management system

IX. Core Differences Comparison Table

The changes in the new version of FMEA are not just about updating the template, but about transforming the way of thinking.

The old version was more of a scoring tool, while the new version is a systematic methodology. It requires teams to first clarify the structural logic and then use data and evidence to support their judgments; it also requires seamless integration of risk analysis and control plans to achieve a closed loop from design to production.

Reposted from: https://mp-weixin-qq-com.translate.goog/s/Csf1Z0lyDIrqlcNBMqVCjQ?_x_tr_sl=auto&_x_tr_tl=en&_x_tr_hl=zh-CN&_x_tr_pto=wapp

Hot Articles

Hot Tags

Manufacturing on Demand

Please fill in the following information to obtain plan details (information is confidential and not disclosed publicly), we will contact you within 24 hours, please keep your phone available!

Upload a 3D/2D model to see instant pricing, lead time, and DFM feedback.